In the high-speed world of fiber optic networks, components like transceivers and cables grab most of the attention. Yet, silently ensuring the seamless operation of these critical elements is a small but vital piece of hardware: the fiber optic cage. Understanding what a fiber optic cage is and its role is essential for anyone designing, deploying, or maintaining robust optical infrastructure. This guide delves deep into the purpose, function, types, and importance of these fundamental components, highlighting their synergy with optical transceivers.

✦ Understanding the Fiber Optic Cage: Core Function

Simply put, a fiber optic cage (also commonly called an optical transceiver cage or cage assembly) is a precision metal housing designed to securely hold, align, and connect an optical transceiver module to a printed circuit board (PCB). It acts as the critical mechanical and electrical interface between the transceiver and the host system.

Think of it as a specialized docking station. Its primary roles are:

Secure Physical Mounting: Provides a robust and vibration-resistant slot for inserting and removing the optical transceiver.

Precise Optical Alignment: Ensures the transceiver's internal optical ports align perfectly with the external fiber optic connectors (LC, SC, MTP/MPO, etc.) plugged into the front panel of the device. This alignment is paramount for minimizing insertion loss and back reflection, which directly impacts signal integrity and transmission distance.

Electrical Connection: Incorporates a socket that mates with the transceiver's electrical edge connector, facilitating high-speed data transfer and communication between the transceiver and the host system's electronics.

Electromagnetic Interference (EMI) Shielding: Constructed primarily from metal (often steel alloys with plating like nickel or gold over copper), the cage forms a Faraday cage around the transceiver. This containment is vital for preventing the transceiver's high-frequency signals from leaking out (interfering with other components) and shielding it from external electromagnetic noise, ensuring signal integrity and regulatory compliance (e.g., FCC, CE).

Thermal Management: Provides a conductive path to help dissipate heat generated by the optical transceiver towards the PCB and potentially a heatsink. While not a primary heatsink itself, its design influences thermal performance.

Latching Mechanism: Integrates features (like bail latches or pull tabs) that work with the transceiver's own latching system for secure insertion and easy, tool-less extraction.

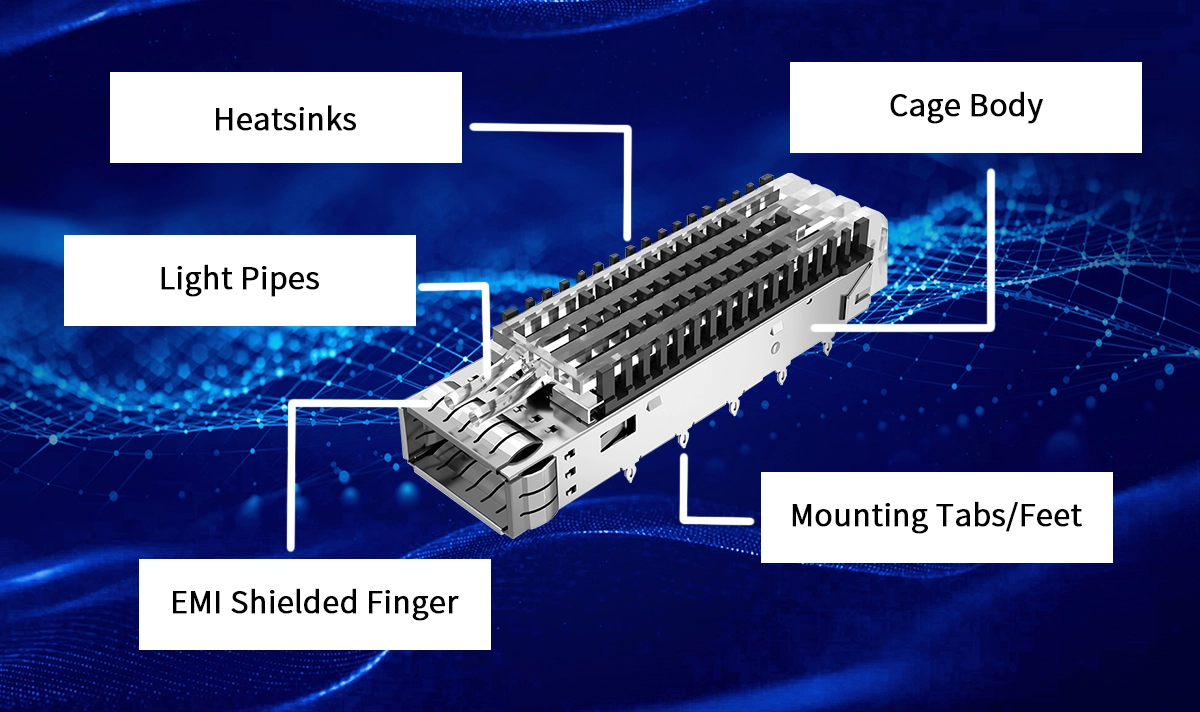

✦ Key Components of a Fiber Optic Cage Assembly

A typical cage assembly consists of several parts:

Cage Body: The main metal housing that surrounds the transceiver.

Shielding Fingers/Tangs: Flexible metal contacts that ensure continuous EMI shielding when the cage is mounted in the chassis cutout and when a transceiver is inserted.

PCB Mounting Tabs/Feet: Structures for soldering the cage securely onto the PCB.

Latching Mechanism Support: Features designed to engage with the transceiver's latching mechanism.

Optional Light Pipes: For cages supporting transceivers with LED status indicators, light pipes may be integrated to channel the light to the front panel.

Optional Heatsinks: Heat generated by the optical transceiver module is transferred through the cage to an external heatsink attached to the cage, facilitating efficient cooling.

✦ Types of Fiber Optic Cages

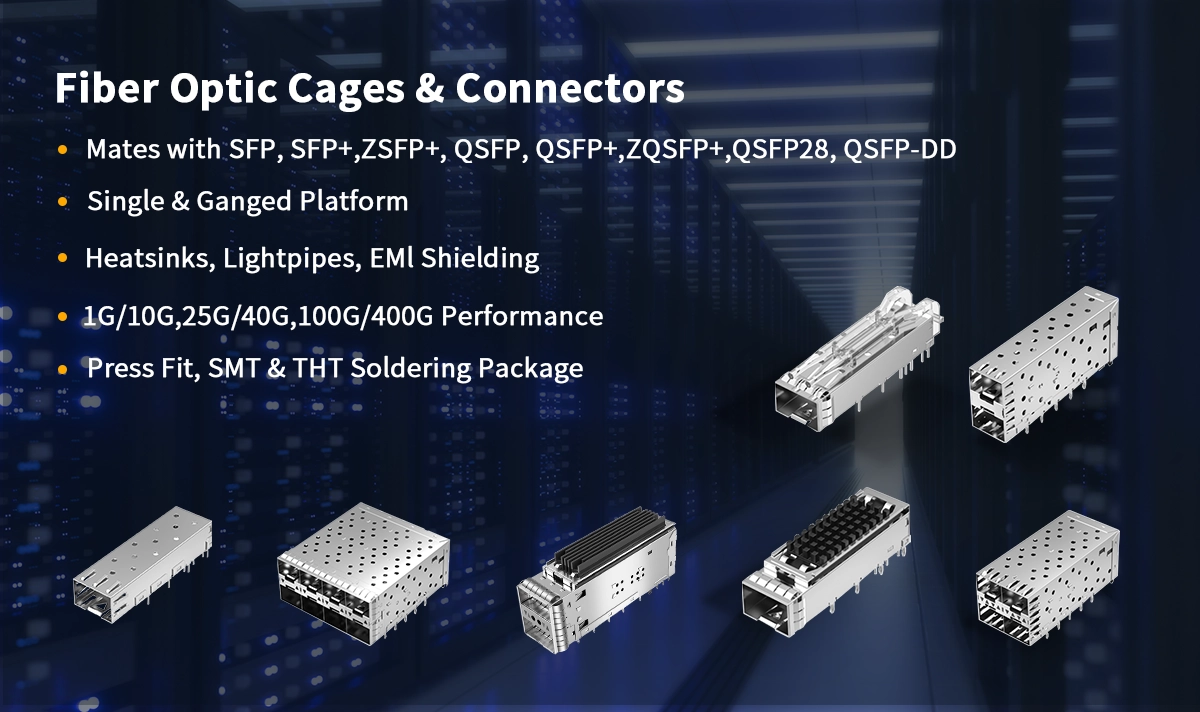

Cages are primarily categorized by the type and number of optical transceiver modules they accommodate, defined by Multi-Source Agreement (MSA) standards:

SFP Cage: Holds a single Small Form-factor Pluggable (SFP, SFP+, SFP28, SFP56) transceiver.

SFP+ Cage: Specifically designed for higher-speed 10 Gigabit SFP+ modules, though often backward compatible with SFP. Key for optical transceiver compatibility in 10G applications.

QSFP Cage: Holds a single Quad Small Form-factor Pluggable (QSFP+, QSFP28, QSFP56, QSFP-DD) transceiver, supporting 40G, 100G, 200G, and 400G speeds. Crucial for high-density fiber optic port density.

QSFP-DD Cage: Designed for the deeper Double Density QSFP-DD modules used for 400G and 800G. Requires specific fiber optic cage dimensions.

Multi-port Cages: Houses 2, 4, or even 8 individual SFP/SFP+ modules within a single cage assembly footprint, optimizing fiber optic port density on a switch line card.

✦ Cage Specifications and Material Choices

Cages are precisely engineered components. Key specifications include:

Compliance: Adherence to relevant MSA standards (SFF-8431 for SFP+, SFF-8636 for QSFP28, SFF-8665 for QSFP-DD, etc.).

Material: Typically stainless steel or specialized copper alloys (like C7025) for optimal EMI performance and spring characteristics. Plating (Sn, Ni/Au) ensures solderability and corrosion resistance.

Port Configuration: Defines the external fiber connector type (LC Duplex, MTP/MPO-12, etc.) the cage is designed for.

Height Profile: Standard or low-profile (for constrained chassis designs).

Thermal Design: Features like open tops for heatsink attachment or integrated thermal pads.

Material Comparison for Optical Transceiver Cages

Material | Primary Advantages | Primary Disadvantages | Common Use Cases |

|---|---|---|---|

Stainless Steel | High strength, good corrosion resistance, cost-effective | Lower electrical conductivity (EMI), less thermal conductivity | Standard SFP/SFP+ cages, cost-sensitive apps |

Copper Alloy (e.g., C7025) | Excellent electrical conductivity (superior EMI shielding), good thermal conductivity | Higher cost, heavier than steel | High-speed cages (QSFP28, QSFP-DD), critical EMI environments |

Phosphor Bronze | Good spring properties (for shielding fingers), decent conductivity | Cost, conductivity less than pure copper | Shielding fingers/tangs within cages |

✦ Why Fiber Optic Cage Quality Matters

Choosing a high-quality optical transceiver cage is non-negotiable for network reliability:

Signal Integrity: Poor alignment or inadequate EMI shielding causes signal degradation, errors (bit errors), and link failures. Fiber optic cage performance directly impacts this.

Transceiver Lifespan: Excessive heat buildup due to poor thermal management or mechanical stress from a subpar cage can shorten transceiver life.

System Reliability: A failing cage interface can cause intermittent connections or complete port failure.

Compliance: Non-compliant cages may fail EMI/EMC regulatory testing, preventing equipment certification or sale.

✦ Selecting the Right Fiber Optic Cage: The LINK-PP Advantage

When sourcing optical transceiver cages, partnering with a reputable manufacturer like LINK-PP is essential. LINK-PP specializes in high-precision optical connectivity solutions, including a comprehensive range of MSA-compliant cages engineered for peak performance and durability.

LINK-PP Fiber Optic Cages are renowned for:

Strict MSA Compliance: Guaranteeing seamless fit and function with all major optical transceiver brands.

Premium Materials: Utilizing high-grade copper alloys and stainless steel with optimal plating for superior EMI shielding and longevity.

Precision Engineering: Ensuring perfect optical alignment and robust mechanical latching for reliable operation.

Rigorous Testing: Undergoing extensive quality control for insertion loss, EMI shielding effectiveness, mechanical durability, and solderability.

Comprehensive Portfolio: Offering cages for all major form factors (SFP+, QSFP28, QSFP-DD, OSFP, etc.) and port configurations (LC, MTP/MPO).

Explore Popular LINK-PP Optic Cage Solutions:

LINK-PP LP14BC01000: High-density 4-port SFP+ cage assembly for LC duplex connectors. Ideal for maximizing fiber optic port density in 10G switches. Download datasheet ➙

LINK-PP LP11BC02100: Single port SFP+ cage assembly designed with light pipe, essential for 10G ethernet applications. Download datasheet ➙

Ensuring Optimal Performance: Cage and Transceiver Compatibility

Always verify that your chosen fiber optic cage is compatible with your specific optical transceiver modules (form factor, speed, connector type) and your host board/chassis design. Refer to the manufacturer's datasheets and application notes. LINK-PP provides detailed technical specifications for all their cage products to simplify this process.

✦ Conclusion: The Vital Link in Your Optical Network

While small, the fiber optic cage is a mission-critical component. It provides the secure, shielded, and precisely aligned environment necessary for optical transceivers to perform reliably at ever-increasing speeds. Neglecting cage quality can lead to network instability, reduced performance, and increased downtime costs.

Ready to enhance your network's reliability and performance? Explore LINK-PP's extensive range of high-quality, MSA-compliant fiber optic cages designed for the most demanding applications.

✦ See Also

Understanding Erbium-Doped Fiber Amplifiers In Optical Systems