When designing Ethernet-based devices—routers, industrial switches, PoE injectors—selecting the right magnetic module is fundamental. Two widely used formats are DIP (through-hole) and SMT (surface-mount) LAN transformers. Each format has strong design implications in terms of mechanical strength, signal integrity, assembly cost, and reliability.

What Are Ethernet Transformers?

Basic Functions

Ethernet transformers, also known as magnetics, are key components in network hardware. They provide electrical isolation, protecting devices from voltage spikes and fault currents. By converting single-ended to differential signals, they improve signal clarity and help reject common-mode noise—essential for Gigabit Ethernet.

These magnetics also reduce EMI (electromagnetic interference) and act as low-pass filters, shaping signals and matching impedance between the network line and the device. Unlike optocouplers, transformers transmit signal power without extra power sources, though they don't support DC signals and require proper line coding.

Note: Many Ethernet designs use discrete or integrated magnetics modules to meet EMI and safety standards.

Role in Ethernet Design

Ethernet magnetics are essential for meeting IEEE 802.3 standards, which require 1500 VRMS isolation. They provide galvanic isolation to protect circuits from surges and include common mode chokes to reduce EMI. Proper PCB layout—especially grounding and routing—further enhances noise suppression.

These LAN transformers support speeds from 10BASE-T to 10GBASE-T, enabling reliable connections in switches, routers, and industrial networks. By ensuring clear signals, electrical isolation, and EMI control, magnetics play a critical role in building robust, high-speed Ethernet systems for data centers, smart buildings, and industrial applications.

DIP vs SMT Ethernet Transformers

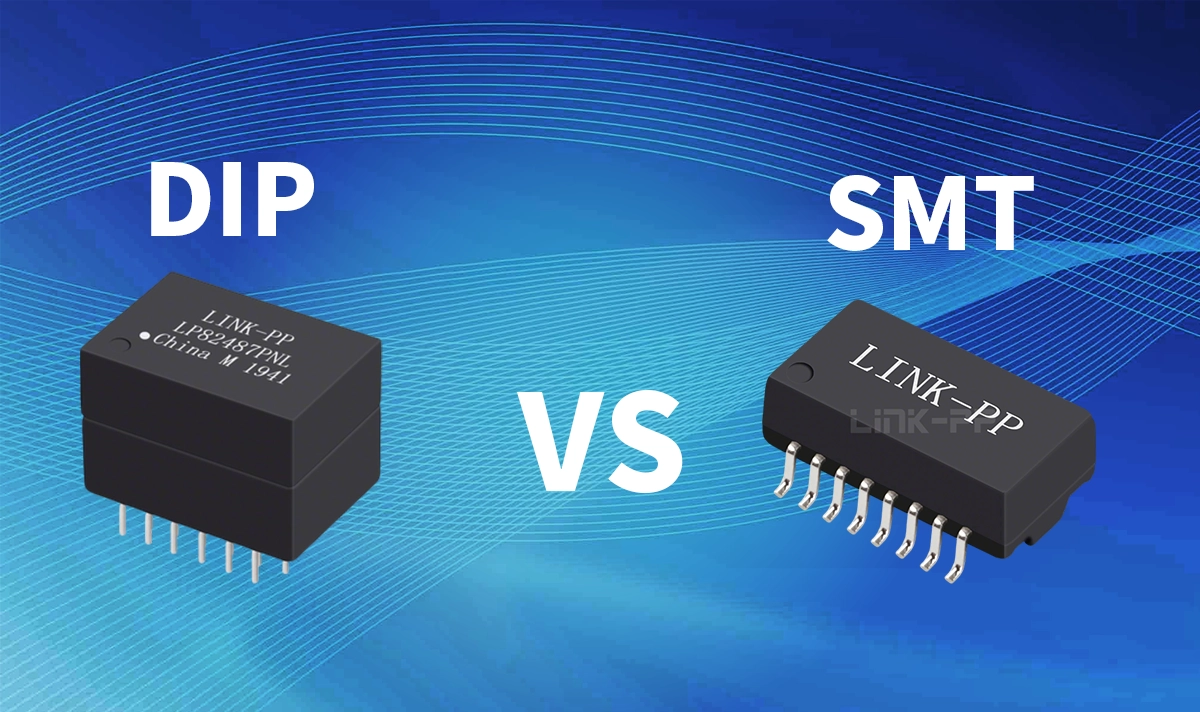

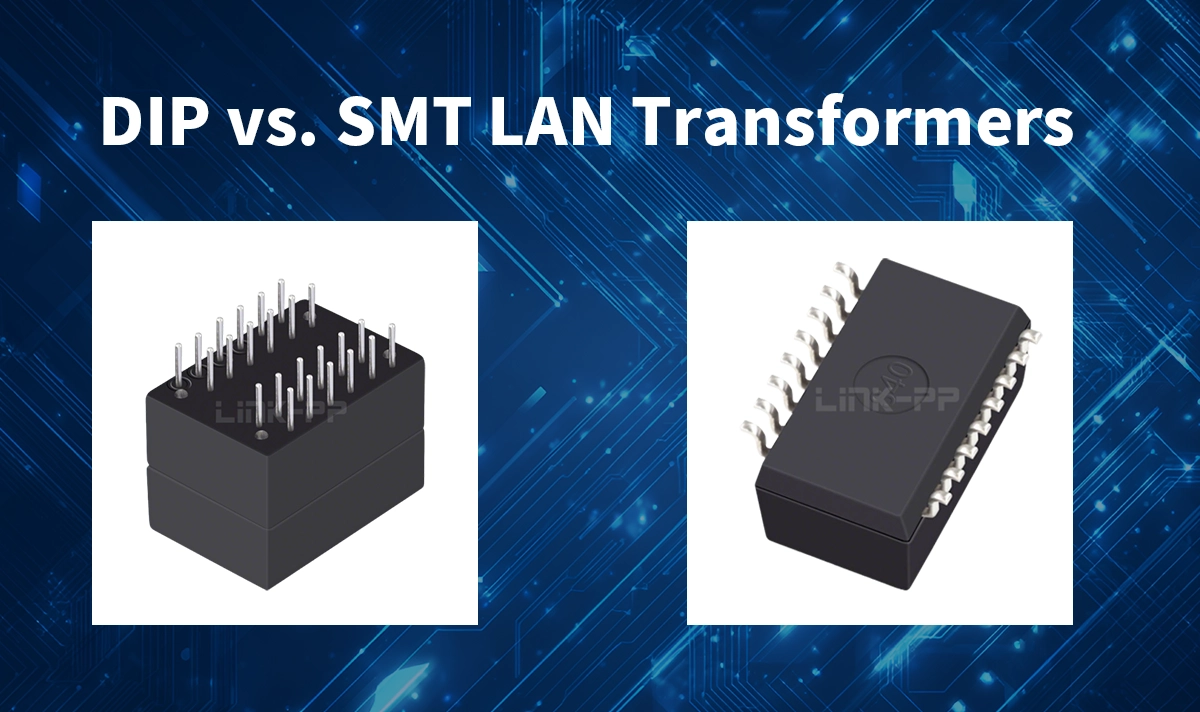

Package & Mounting: What Sets Them Apart

DIP (Dual In-Line Package) uses long leads inserted into PCB holes, soldered typically via wave soldering.

SMT (Surface-Mount Technology) attaches components directly onto PCB pads using reflow soldering, supporting higher component density.

Key Differences

Feature | DIP LAN Transformer | SMT LAN Transformer |

|---|---|---|

Assembly Method | Manual/insertion machine + wave solder | Automated pick-and-place + reflow |

Board Area | Larger footprint, lower density | Compact, high density |

Mechanical Strength | Superior robustness; ideal for vibration environments | Good, but less suited for shock stress |

High-Frequency Performance | Increased lead inductance may affect crosstalk | Short leads = improved signal integrity |

Production Efficiency | Lower throughput; labor-intensive | High-speed mass production |

Ease of Maintenance | Easy to replace; plug-in friendly | Harder to rework due to dense placement |

Cost Considerations | Higher labor cost, lower part cost | Lower assembly cost, higher initial machine investment |

Real-World Implications in Ethernet Design

Industrial and Outdoor Networking: DIP modules excel in harsh environments (vibration, temperature shifts, shock). They offer strong solder joints and thru-hole retention.

Consumer & Space-Constrained Designs: SMT transformers are ideal for compact, high-density boards in PCs, cameras, routers.

Signal Integrity: At gigabit speeds, SMT's short interconnect paths reduce crosstalk and insertion loss, a key advantage in high-frequency signals.

Maintenance & Prototyping: DIP components are easily hand-soldered and replaced, making them ideal for field-tested or user-serviceable products.

Hybrid Use & Selection Tips

Modern PCB designs often combine both formats:

Use SMT LAN transformers for most data ports where space and performance are premium.

Reserve DIP options for PoE channels, power-handling ports, or connectors in rugged applications.

Designers should consider:

Vibration, shock & thermal profile

Signal bandwidth and EMI requirements

Cost vs assembly volume

Serviceability and prototyping needs

Conclusion

No single package is perfect. DIP transformers excel where reliability and manual serviceability are prioritized, while SMT modules dominate in space- and cost-sensitive, high-frequency applications.

From a holistic Ethernet design standpoint, choosing the right type—or combining both—ensures optimal electrical performance, manufacturability, and field reliability. That is why LINK‑PP offers both robust DIP LAN transformers and compact SMT magnetics to suit varied application demands.

FAQ

What is the main difference between DIP and SMT Ethernet transformers?

DIP transformers are put into holes on the board. They are very strong and last a long time. SMT transformers sit flat on top of the board. They help save space and fit in small places. Engineers pick DIP for rough places. They use SMT when they need to make many small devices.

Can SMT Ethernet transformers handle industrial environments?

Some SMT transformers can work in hard places. Makers build them to handle hot and cold and block strong EMI. DIP transformers are still better for shaking and last longer in factories.

Do both types support Power over Ethernet (PoE)?

Yes, both DIP and SMT transformers can work with PoE. Designers should check the datasheet to make sure about PoE and isolation voltage. Most new transformers follow IEEE rules for PoE.

Which type is easier to replace during prototyping?

DIP transformers are simple to take out and put back in. Their leads go through the board, so you can swap them fast. SMT transformers need special tools and careful work so you do not break the board.

How do I choose the right transformer for my project?

Tip: Write down what your project needs, like space, strength, speed, and how you will put it together. Match these needs to what the transformer can do. Look at datasheets and ask LINK-PP Team to help you pick the best one.