🌐 Introduction

EtherCAT (Ethernet for Control Automation Technology) is a high‑performance, real‑time Industrial Ethernet protocol widely adopted in automation, robotics, CNC machinery, and smart factory applications. With deterministic timing, ultra‑low communication latency, and sub‑microsecond synchronization, EtherCAT has become a foundational technology for modern motion control and high‑speed industrial systems.

This guide provides a professional, engineering‑level explanation of EtherCAT’s operating principles, synchronization mechanisms, topology options, safety standards, and physical‑layer considerations.

🌐 Limitations of Traditional Ethernet in Industrial Automation

Standard Ethernet was originally designed for office environments—not for synchronized, deterministic industrial control. Key limitations include:

Non‑deterministic communication caused by CSMA/CD arbitration

High protocol overhead due to multi‑layer processing

High jitter is unsuitable for motion control loops

Poor scalability when many devices are connected in a time‑critical system

Industrial applications such as robotics and multi‑axis servomotion often require cycle times under 100 µs and jitter measured in hundreds of nanoseconds or less. Traditional Ethernet cannot meet these constraints.

EtherCAT directly addresses these real‑time challenges with a hardware‑accelerated communication model designed specifically for high‑performance automation.

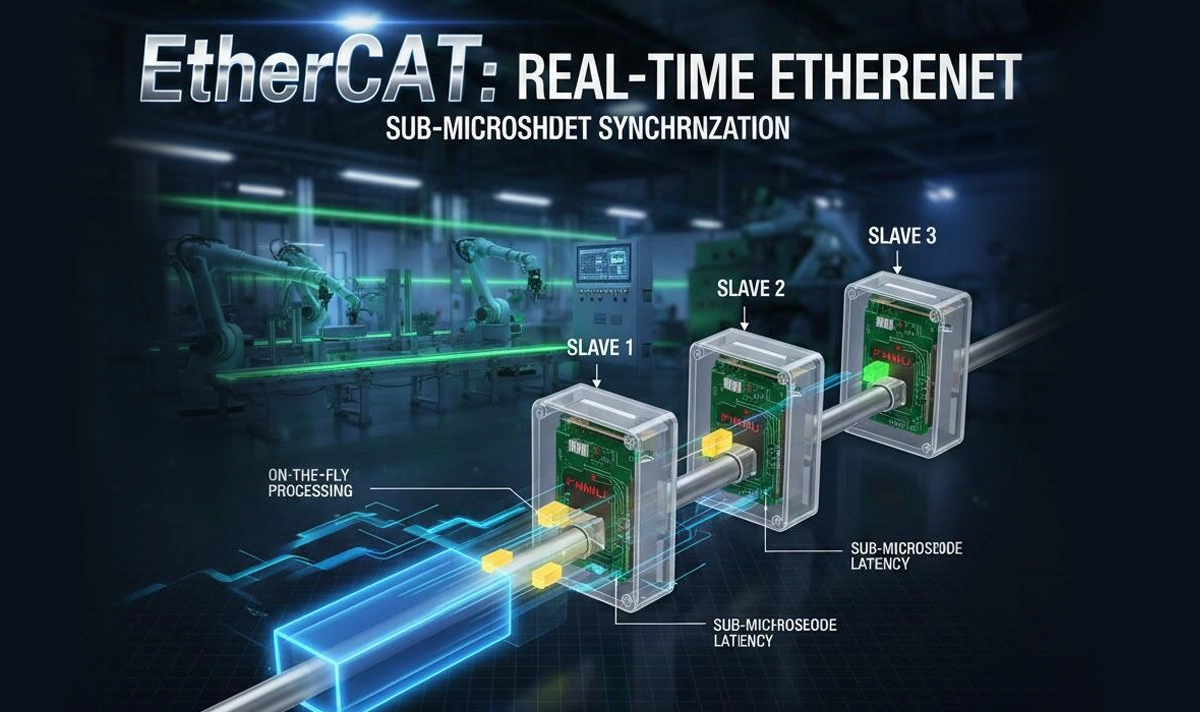

🌐 Core Principle: On‑the‑Fly Frame Processing (FMMU)

The fundamental concept that differentiates EtherCAT from other Industrial Ethernet systems is its method of processing Ethernet frames on the fly, enabled by a hardware unit known as the FMMU (Fieldbus Memory Management Unit).

● How EtherCAT Processes Data

Single Frame Transmission: The EtherCAT master sends one standard Ethernet frame containing datagrams for all slave devices.

On‑the‑Fly Hardware Processing: Each slave extracts its output data and inserts its input data directly into the frame as it passes by. Typical processing delay per slave is < 1 µs.

Frame Loopback: The modified frame returns to the master with consolidated input data from all slaves.

● Performance Characteristics

Deterministic latency independent of node count

Bandwidth utilization > 90%

Example performance:

1000 digital I/O points in ~30 µs

100 servo axes in ~100 µs

This efficiency makes EtherCAT one of the fastest industrial networks available today.

🌐 Distributed Clocks (DC): Sub‑Microsecond Synchronization

Precise synchronization is essential for coordinated robotics, CNC machining, and multi‑axis servomotion. EtherCAT achieves synchronization better than 100 ns using a decentralized, clock‑distribution mechanism.

▷ DC Operating Principle

Reference Clock Selection: The first DC‑capable slave acts as the reference clock.

Timestamp Capture: Each slave measures frame arrival and departure times to determine propagation delay.

Automatic Drift Compensation: The master computes offsets and distributes correction values to all slaves.

▷ Benefits of DC Synchronization

Nanosecond‑level phase alignment across hundreds of devices

Extremely stable motion profiles for robotics and positioning systems

Accurate simultaneous data acquisition

The DC system provides deterministic and precise network timing without requiring a centralized master clock.

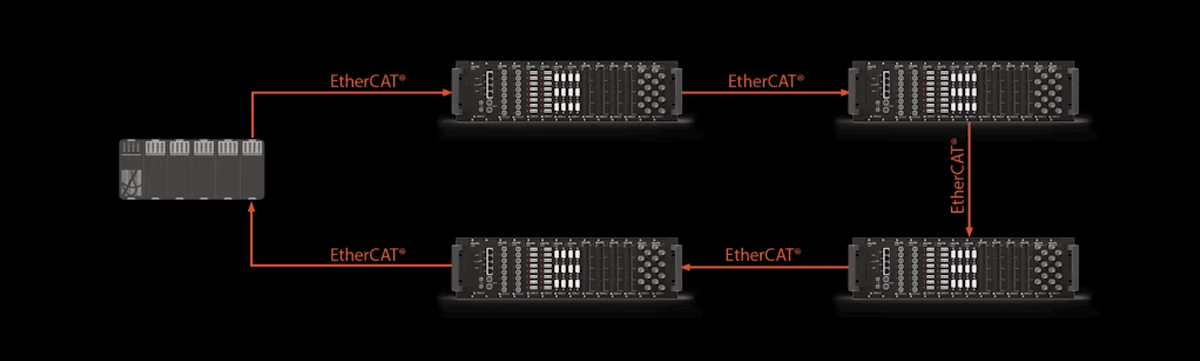

🌐 Flexible Network Topology and Redundancy

EtherCAT supports a wide range of wiring topologies without requiring Ethernet switches.

1. Supported Topologies

Line (most common)

Tree / Branch / Drop Line

Star (using EtherCAT junctions)

Ring (full media redundancy)

2. Fault Tolerance

In a ring structure, if a cable breaks:

The frame automatically reverses direction

Communication with the remaining network continues uninterrupted

This ensures high availability in demanding industrial environments.

🌐 Functional Safety over EtherCAT (FSoE)

EtherCAT integrates functional safety within the same network using FSoE, a TÜV‑certified protocol supporting SIL 3 (IEC 61508).

Examples of safety functions:

Emergency stop

Safe Torque Off (STO)

Safe Speed Monitoring (SSM)

Safe limited position or direction monitoring

By embedding safety data inside standard EtherCAT frames, FSoE eliminates the need for a separate safety bus, reducing cost and wiring complexity.

🌐 Role of Physical Layer Components in EtherCAT Performance

While EtherCAT’s performance is protocol‑driven, its real‑time integrity relies heavily on physical‑layer hardware quality.

Key requirements include:

High signal integrity under heavy EMI conditions

Excellent common‑mode noise rejection

Reliable transformer‑based galvanic isolation

Industrial‑grade RJ45 integrated magnetic connectors

High‑quality magnetics and PHY components enable EtherCAT systems to maintain microsecond‑level timing and nanosecond‑level synchronization even in electrically noisy environments.

🌐 Global Adoption and Application Domains

EtherCAT is one of the fastest‑growing Industrial Ethernet technologies worldwide, supported by the EtherCAT Technology Group (ETG). Its high performance and open architecture drive widespread use in:

Semiconductor equipment

Robotics and automation systems

CNC machines and high‑precision machining

Packaging machinery

Wind turbines and renewable energy systems

Smart factory / Industry 4.0 infrastructure

Its scalability, low cost, and real‑time capability have made EtherCAT a global automation standard.

🌐 Summary of Technical Advantages

Feature | Technical Benefit | Impact on Control System |

|---|---|---|

On‑the‑Fly Processing | Eliminates protocol‑stack overhead | Deterministic, ultra‑low latency |

Distributed Clocks | <100‑ns synchronization | High‑precision multi‑axis control |

Flexible Topologies | Supports Line, Tree, Star, Ring | Simplified wiring, lower costs |

FSoE Integration | SIL3‑certified functional safety | Unified safety + control network |

🌐 Conclusion

EtherCAT delivers industry‑leading real‑time performance through deterministic communication, efficient bandwidth usage, and nanosecond‑level synchronization. Its flexible topology, integrated functional safety, and robust physical‑layer requirements make it a foundational technology for next‑generation industrial automation.

For engineers developing motion control, robotics, CNC, or high‑performance automation systems, EtherCAT offers an unparalleled balance of speed, reliability, and scalability.