📐Introduction

When working with high-speed optical transceivers such as SFP+ modules, it is not only the electrical interface that matters. The mechanical design plays an equally critical role in ensuring signal integrity, reliable operation, and long-term compatibility. The SFF-8432 specification, also known as the Improved Pluggable Formfactor (IPF) standard, defines the mechanical requirements for SFP+ modules and their cages. This standard has become essential for manufacturers, system designers, and network operators aiming for seamless interoperability.

📐What is SFF-8432?

SFF-8432 is a specification maintained by the Small Form Factor (SFF) Committee. Unlike communication protocols, SFF-8432 focuses on the physical and mechanical aspects of SFP+ transceivers. It sets the framework for:

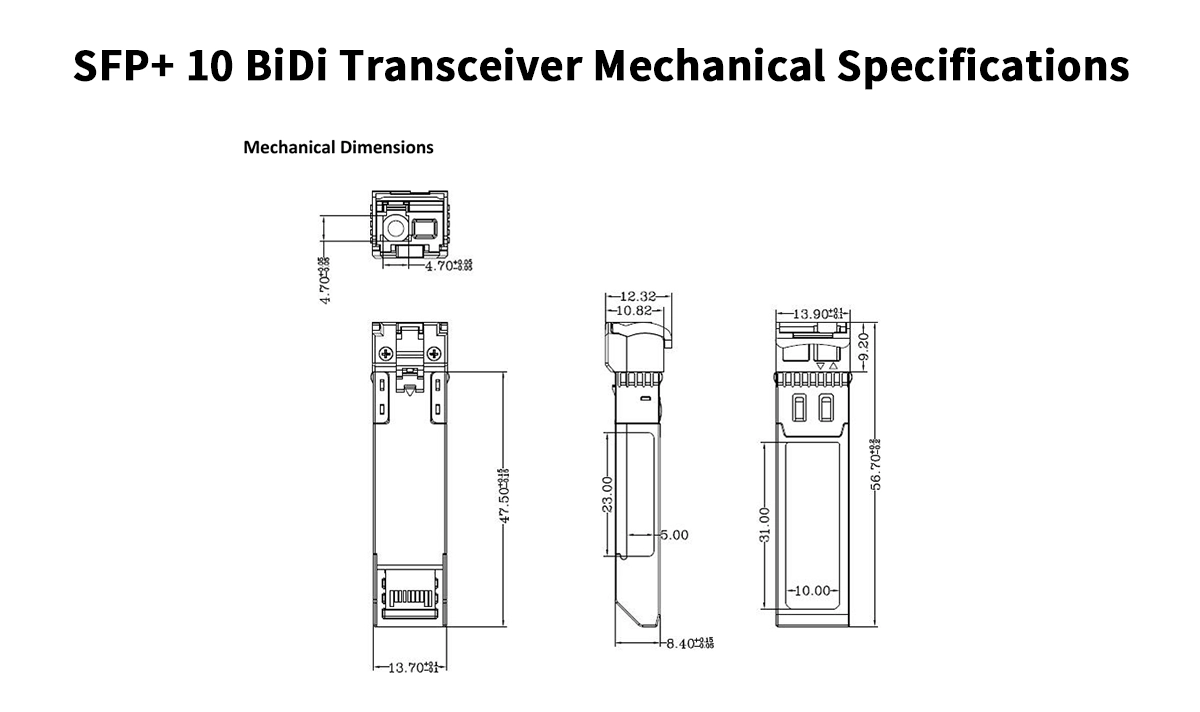

Module dimensions and tolerances

Insertion and retention forces

Durability across repeated mating cycles

EMI (Electromagnetic Interference) shielding when paired with compliant cages

This ensures that SFP+ modules from different vendors can operate interchangeably, supporting the global networking equipment ecosystem.

📐Key Features of the SFF-8432 Standard

1. Mechanical Interoperability

SFF-8432 modules are designed to fit standard SFP+ cages, providing backwards compatibility with earlier SFF-8074 designs. This consistency allows system builders to mix and match components from multiple vendors without mechanical conflicts.

2. EMI Performance

The standard specifies cage and module designs that improve electromagnetic shielding. When combined with an IPF-compatible cage, SFP+ modules achieve significantly better EMI containment, which is critical in high-density data center environments.

3. Insertion and Retention Requirements

Insertion Force: ≤ 18 N

Withdrawal Force: ≤ 12.5 N

Retention Force: 90–170 N

Durability: At least 50 insertion cycles without mechanical or functional damage

These requirements ensure that modules remain securely connected while still being serviceable in the field.

4. Contact Sequence Design

The connector layout ensures that ground pins mate first, followed by power, and finally high-speed signal contacts. This staged connection helps prevent electrical damage during hot-swapping.

📐Why SFF-8432 Matters in Modern Networking

As data rates scale to 10Gbps and beyond, physical stability and EMI resistance are no longer optional. The SFF-8432 standard addresses these challenges by:

Supporting higher port densities in switches and servers

Minimizing system downtime caused by mechanical wear

Enabling reliable hot-swappable transceivers in mission-critical environments

For system integrators, compliance with SFF-8432 ensures long-term interoperability and reduces risks of vendor lock-in.

📐LINK-PP’s Role in SFF-8432 Compliance

At LINK-PP, we design and manufacture 10G SFP+ optical transceiver modules that fully align with SFF-8432 requirements. Our modules deliver stable performance across diverse networking platforms while meeting the highest mechanical and EMI standards.

Explore our 10G SFP+ Modules to see how LINK-PP supports enterprises, telecom providers, and data centers with reliable and compliant optical solutions.

📐Conclusion

The SFF-8432 specification may not define transmission speeds or protocols, but its role is just as vital. By standardizing the mechanical design of SFP+ modules and cages, it ensures that optical transceivers operate reliably in high-performance networks. For organizations seeking future-proof connectivity, adopting modules that meet SFF-8432 requirements—such as those from LINK-PP—is a critical step.