In our electronics-driven world, the Printed Circuit Board Assembly (PCBA) is an indispensable core. It's the lifeblood of nearly every gadget, enabling functionality and connectivity. This article provides a clear, professional explanation of "What is PCBA?", covering its definition, significance, manufacturing, and widespread role. Understanding PCBA is key to comprehending the technology that shapes our modern lives.

PCBA Fundamentals

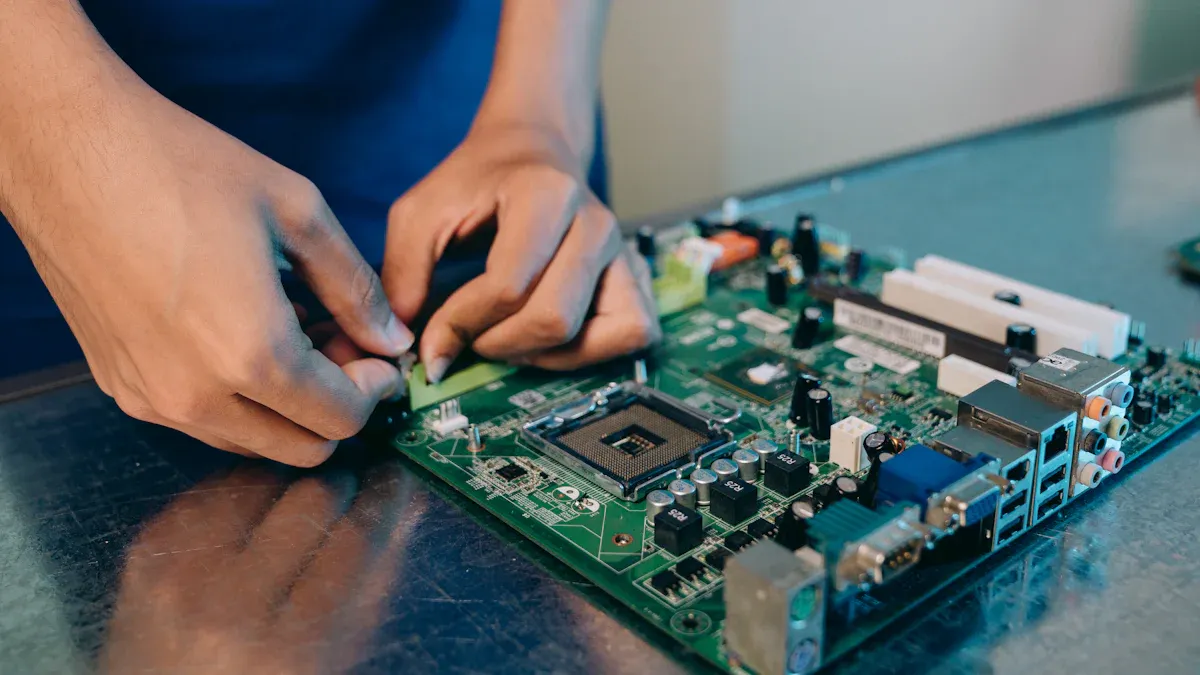

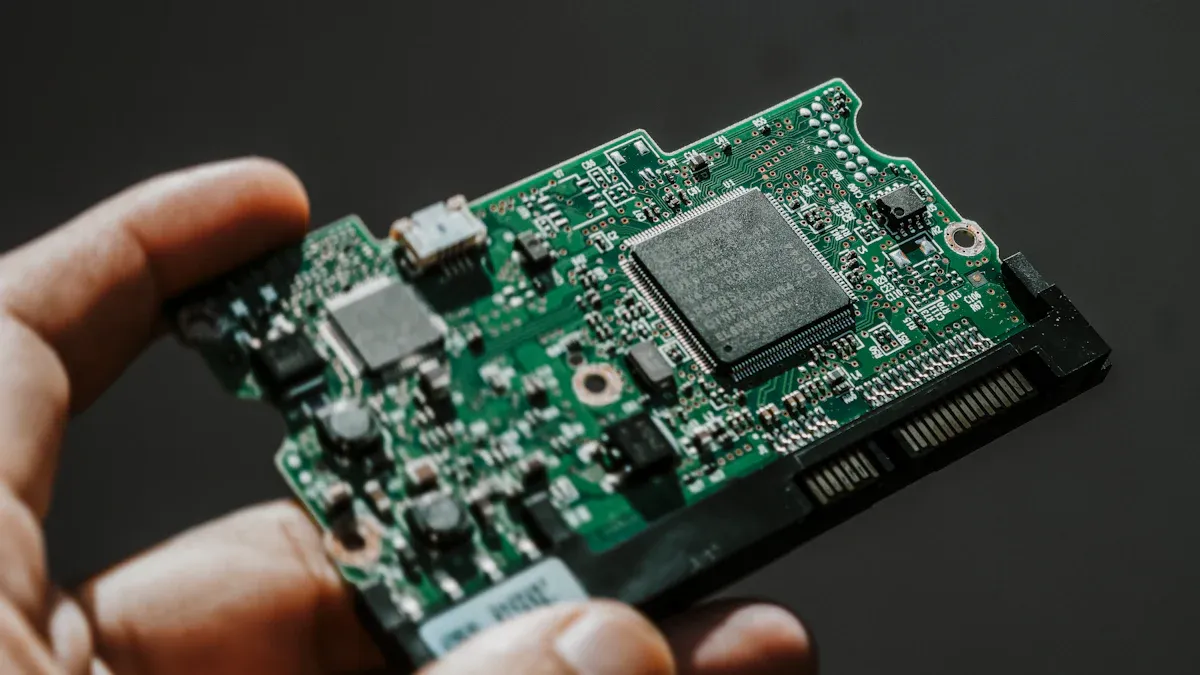

PCBA (Printed Circuit Board Assembly): The process of mounting and soldering electronic components onto a PCB (Printed Circuit Board) to create a fully functional circuit. It involves multiple stages, including design, fabrication, component placement, and testing.

PCB vs. PCBA:

Term | Definition |

|---|---|

PCBA | A populated PCB with components like resistors, capacitors, ICs, and connectors. |

PCB | A bare board with conductive pathways (traces) but no components. |

The PCBA Process-The Journey from PCB to PCBA

The transformation from a bare PCB to a functional PCBA involves several meticulous steps:

Component Procurement: Sourcing all necessary electronic components based on the design specifications.

Solder Paste Application: Applying solder paste to the PCB's pads where components will be placed.

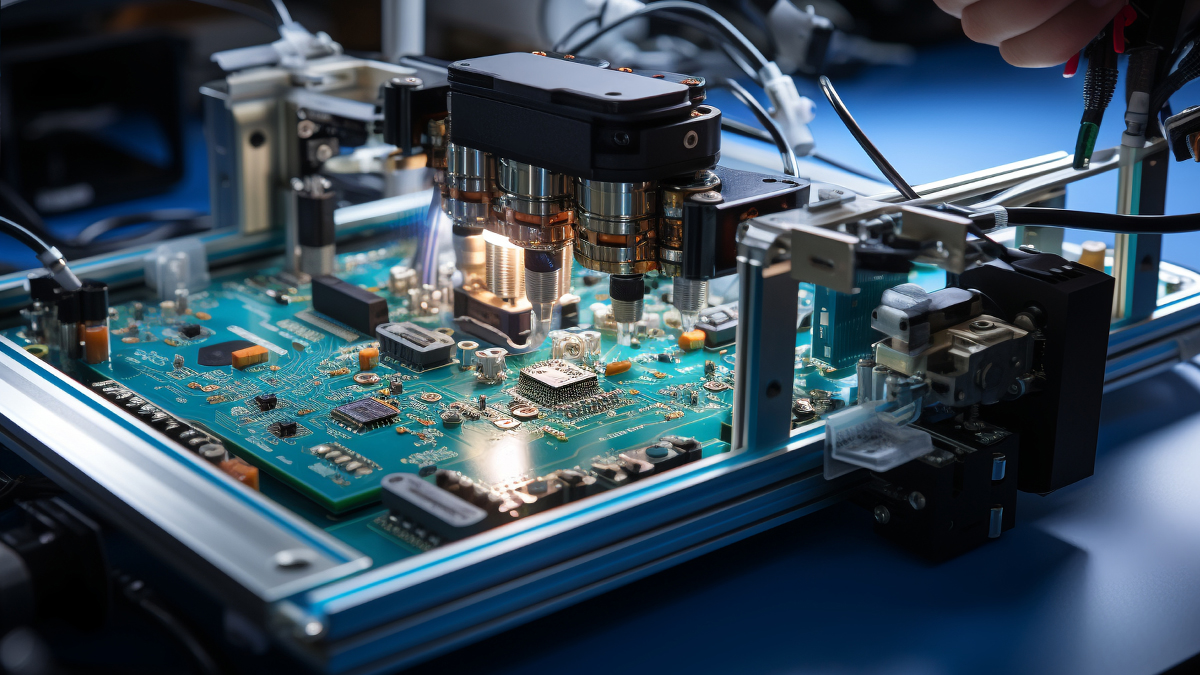

Component Placement: Using automated machines to accurately place components onto the PCB.

Soldering: Securing components to the PCB through reflow soldering (for Surface Mount Technology) or wave soldering (for Through-Hole Technology).

Inspection and Testing: Conducting thorough inspections, including Automated Optical Inspection (AOI) and X-ray inspection, followed by functional testing to ensure the assembly meets quality standards.

These steps ensure that the PCBA functions as intended, with high reliability and performance.

Applications of PCBA

Consumer Electronics: Smartphones, laptops, TVs, and gaming consoles rely on complex PCBAs.

Automotive: Engine control units (ECUs), ADAS, and infotainment systems use robust PCBAs.

Medical Devices: Diagnostic equipment, monitoring systems, and implantables depend on highly reliable PCBAs.

Industrial Equipment: Automation, robotics, and control systems utilize rugged PCBAs.

Telecommunications: Routers, switches, and base stations incorporate advanced PCBAs. For instance, specialized components like LINK-PP's RJ45 connectors with integrated magnetics are mounted on these PCBAs, crucial for network performance.

Conclusion: The Indispensable Core

The Printed Circuit Board Assembly (PCBA) is the engineered heart of modern electronics. It transforms a bare board into a functional unit, powering countless devices across industries. Understanding "What is PCBA?" is crucial for appreciating the technology underpinning our digital world, a technology poised for continued evolution and innovation.

FAQ

What is the difference between SMT and THT in PCBA?

Surface Mount Technology (SMT) places components directly on the PCB surface. Through-Hole Technology (THT) inserts components into drilled holes. SMT is faster and ideal for compact designs. THT offers stronger connections, making it suitable for high-stress applications.

How do you ensure the quality of a PCBA?

You ensure quality through inspection and testing. Automated Optical Inspection (AOI) detects errors like misaligned components. Functional testing verifies the board’s performance. Environmental stress tests simulate extreme conditions to check reliability.

Can PCBA be repaired if damaged?

Yes, you can repair a damaged PCBA. Techniques like soldering or replacing faulty components restore functionality. However, repair feasibility depends on the damage severity and the board’s complexity.

Why is lead-free soldering important in PCBA?

Lead-free soldering complies with environmental regulations like RoHS. It reduces toxic waste and aligns with sustainable practices. Although it requires higher temperatures, it ensures safer and eco-friendly manufacturing.

What industries benefit most from PCBA?

Industries like consumer electronics, automotive, healthcare, and telecommunications benefit greatly. PCBA enables compact designs, reliable performance, and advanced features in devices ranging from smartphones to medical equipment.