🔹 Introduction

As industrial systems continue moving toward distributed, data-driven architectures, Industrial PCs (IPCs) increasingly operate as edge computing nodes that must exchange large volumes of data with controllers, gateways, and cloud platforms. In harsh electrical environments, copper-based Ethernet may face bandwidth or EMI limitations—making fiber connectivity essential.

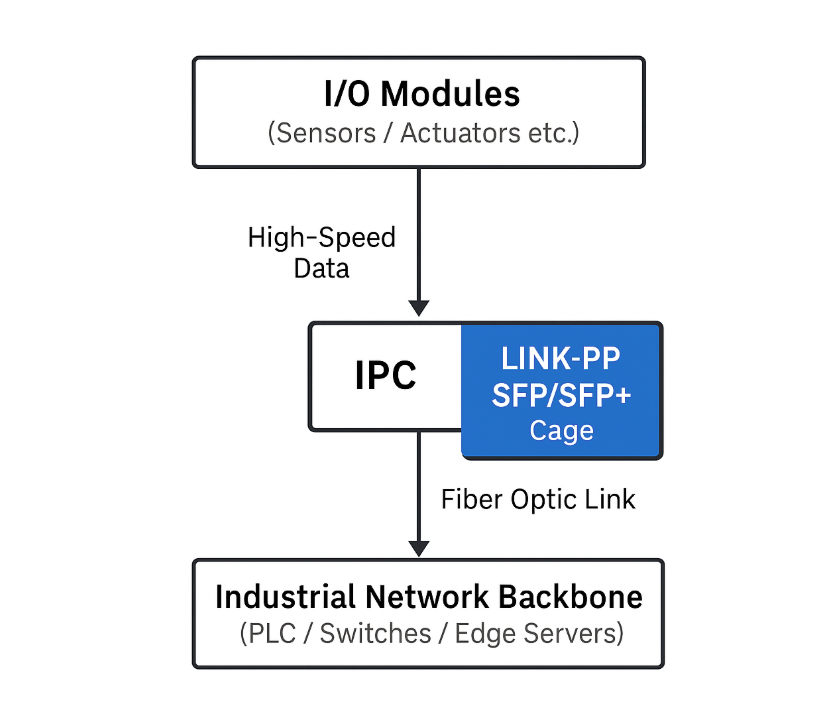

This case study illustrates how an IPC deployed at the industrial edge uses LINK-PP SFP/SFP+ cages and modules to build a robust, high-speed optical link for long-distance, low-latency communication.

🔹 Why SFP/SFP+ Cages Matter in Industrial IPCs

SFP (1G) and SFP+ (10G) cages serve as the mechanical and electromagnetic interface between an IPC’s network controller and a pluggable optical transceiver. Their role is often underestimated, but in industrial systems, they directly influence reliability, thermal stability, and long-term performance of fiber modules.

Key Functions

Mechanical Protection: Rigid metal cage secures the SFP/SFP+ module in place, preventing vibration-related signal dropouts.

EMI Shielding: A conductive cage structure creates a protected environment, maintaining signal integrity even in the presence of motors, drives, and high-power equipment.

Thermal Support: Optimizes airflow and heat dissipation for long-duration operation.

Standards Compatibility: Supports MSA-compliant SFP/SFP+ transceivers used in industrial fiber networks.

Advantages of Industrial Networking

Enables low-latency, long-distance fiber communication

Reduces EMI exposure compared with copper links

Supports edge computing workloads requiring high bandwidth

Ensures stable operation in rugged environments (temperature, vibration, noise)

🔹 Case Scenario: IPC + SFP Cage + Edge Computing

Application: Smart manufacturing edge node transmitting high-resolution sensor data to a central controller and cloud analytics platform.

Workflow

IPC deployed at the industrial edge processes real-time vision, motion, and I/O data.

The IPC uses an SFP/SFP+ port for uplink to a plant network backbone or data center aggregation switch.

LINK-PP SFP/SFP+ cages ensure the optical module maintains stable electrical contact, EMI shielding, and secure retention during vibration.

Data reaches the PLC or cloud infrastructure with high bandwidth, low latency, and zero packet loss—even across long fiber runs.

🔹 Why Integrators Choose LINK-PP

LINK-PP’s SFP/SFP+ cages and connectors are engineered for industrial environments, supporting:

1G/10G fiber uplinks

Rugged system designs (EMI-sensitive environments)

High vibration and continuous operation

Broad compatibility with standard SFP/SFP+ optical modules

Their proven performance makes them ideal for edge IPCs, factory control networks, industrial switches, and high-speed data acquisition systems.

🔹 Conclusion

As smart factories demand higher data throughput and cleaner electromagnetic performance, fiber-based uplinks using SFP/SFP+ modules have become essential. LINK-PP’s SFP/SFP+ cages provide the mechanical robustness, EMI protection, and long-term stability required for industrial IPCs operating at the edge.

These components ensure that the IPC can maintain consistent, high-speed links to PLCs, SCADA systems, industrial switches, or cloud platforms—supporting the next generation of industrial automation and data intelligence.