In today’s connected industrial landscape, Supervisory Control and Data Acquisition (SCADA) systems are the foundation of modern automation and remote monitoring. SCADA solutions enable operators to collect, analyze, and act on real-time data from distributed assets, ensuring process efficiency, safety, and reliability across manufacturing plants, utilities, energy grids, and smart infrastructure.

▶ What Is a SCADA System?

SCADA — short for Supervisory Control and Data Acquisition — is a control system architecture that uses computers, networked data communications, and graphical interfaces to monitor and control industrial processes.

According to the National Institute of Standards and Technology (NIST), a SCADA system “gathers and processes data, and applies operational controls over long distances.” This makes it an essential technology for remote or large-scale operations such as power distribution, oil pipelines, and water treatment facilities.

Simply put, SCADA connects field devices (like sensors and actuators) to a central control station, enabling continuous supervision, data logging, and decision-making.

▶ Why SCADA Systems Matter

As industries move toward digital transformation, SCADA systems play a critical role in connecting operational technology (OT) with information technology (IT). The following trends define their growing importance:

Operational Efficiency: Real-time data improves productivity and reduces downtime.

Remote Asset Control: SCADA enables monitoring of assets across vast geographical areas.

IoT and Edge Integration: Next-generation SCADA leverages IoT devices and edge computing for smarter data analytics.

Regulatory Compliance: Reliable data collection supports safety, environmental, and quality standards.

Cybersecurity Awareness: Protecting SCADA networks against cyber threats is now a top operational priority.

▶ SCADA Architecture and Core Components

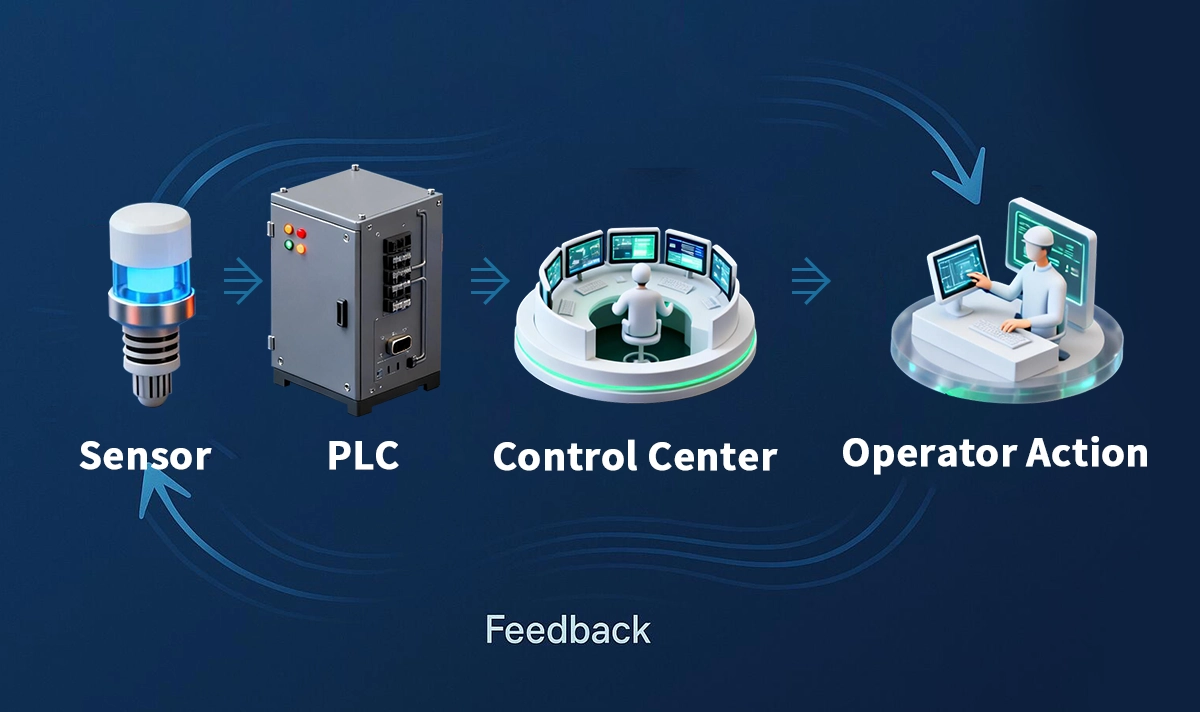

A SCADA system is typically organized into several functional layers:

Field Devices and Sensors

Collect data such as pressure, temperature, flow, and voltage from equipment in the field.Remote Terminal Units (RTUs) or Programmable Logic Controllers (PLCs)

Execute local control logic and communicate with the supervisory server.Communication Network

Transmits data between remote devices and control centers using Ethernet, fiber optics, or wireless connections.

LINK-PP provides high-performance Ethernet magnetic connectors, RJ45 jacks, and SFP optical transceivers designed for reliable SCADA communication.SCADA Server and HMI (Human-Machine Interface)

Centralized systems that visualize process data, generate alarms, and allow operators to control operations.Database and Historian

Store long-term operational data for performance tracking, reporting, and predictive maintenance.

▶ Main Functions of a SCADA System

Data Acquisition: Collects and digitizes sensor information.

Real-Time Monitoring: Displays process variables via operator dashboards.

Supervisory Control: Enables human or automated commands to adjust system parameters.

Alarm Management: Alerts operators to abnormal conditions or failures.

Data Logging and Reporting: Provides historical data for analysis and compliance.

Decision Support: Assists in optimizing operations and resource allocation.

▶ Key Application Areas

SCADA systems are widely used across industries where real-time monitoring and control are essential:

Power Generation and Distribution – monitoring substations, transformers, and grid performance.

Oil and Gas – controlling drilling sites, storage tanks, and pipelines.

Water and Wastewater Management – regulating flow rates, pressure, and water quality.

Manufacturing and Industrial Automation – ensuring production consistency and efficiency.

Transportation and Smart Infrastructure – managing tunnels, traffic systems, and railway networks.

In all these sectors, LINK-PP connectivity components — such as industrial RJ45 connectors, PoE magnetic transformers, and fiber optic transceivers — provide the high-speed, interference-resistant links that SCADA systems depend on.

▶ Emerging Trends in SCADA Systems

Edge Computing and IoT Integration

SCADA is evolving to incorporate IoT sensors and edge intelligence for faster decision-making and reduced latency.Cloud-Based SCADA

Cloud architectures improve scalability, accessibility, and disaster recovery for remote facilities.Cybersecurity Reinforcement

With more connected assets, security measures such as network segmentation, encryption, and intrusion detection are crucial.AI and Predictive Maintenance

Machine-learning algorithms analyze SCADA historical data to predict equipment failures and optimize maintenance schedules.Standardization and Interoperability

Support for modern industrial protocols, such as OPC UA, Modbus TCP, and IEC 60870, ensures cross-vendor compatibility.

▶ Best Practices for Implementing SCADA

Design a scalable and modular architecture.

Use reliable, shielded communication hardware for noise-resistant data transfer.

Integrate redundancy for mission-critical operations.

Employ strict user access control and cybersecurity policies.

Regularly analyze SCADA data for continuous improvement.

▶ Conclusion

Supervisory Control and Data Acquisition (SCADA) systems are at the heart of industrial automation, providing real-time visibility and control over critical infrastructure. As industries adopt smarter, interconnected solutions, the combination of robust networking hardware and secure SCADA architecture becomes vital for ensuring efficiency and reliability.

With advanced Ethernet magnetic solutions and optical transceivers, LINK-PP continues to support the evolving needs of SCADA, IoT, and industrial communication systems worldwide.