▶ Introduction

In today’s rapidly advancing industrial world, the Programmable Logic Controller (PLC) remains the foundation of automation and process control. A PLC is a robust industrial computer that continuously monitors inputs, executes programmed logic, and controls outputs to manage machinery and production systems.

Since its introduction in the late 1960s, the PLC has evolved from replacing hard-wired relay panels to becoming a highly flexible and networked control platform essential to modern manufacturing and smart factories.

This article provides a detailed overview of PLCs — including their definition, architecture, module types, working principles, and real-world applications — offering insights for engineers, integrators, and industrial automation professionals.

▶ What Is a PLC?

A Programmable Logic Controller (PLC) is a digital control device designed to operate reliably in demanding industrial environments that may involve vibration, temperature variations, or electrical interference.

According to the National Institute of Standards and Technology (NIST), a PLC is “a solid-state control system that stores user-programmed instructions for implementing functions such as input/output control, logic, timing, counting, PID control, communication, arithmetic, and data processing.”

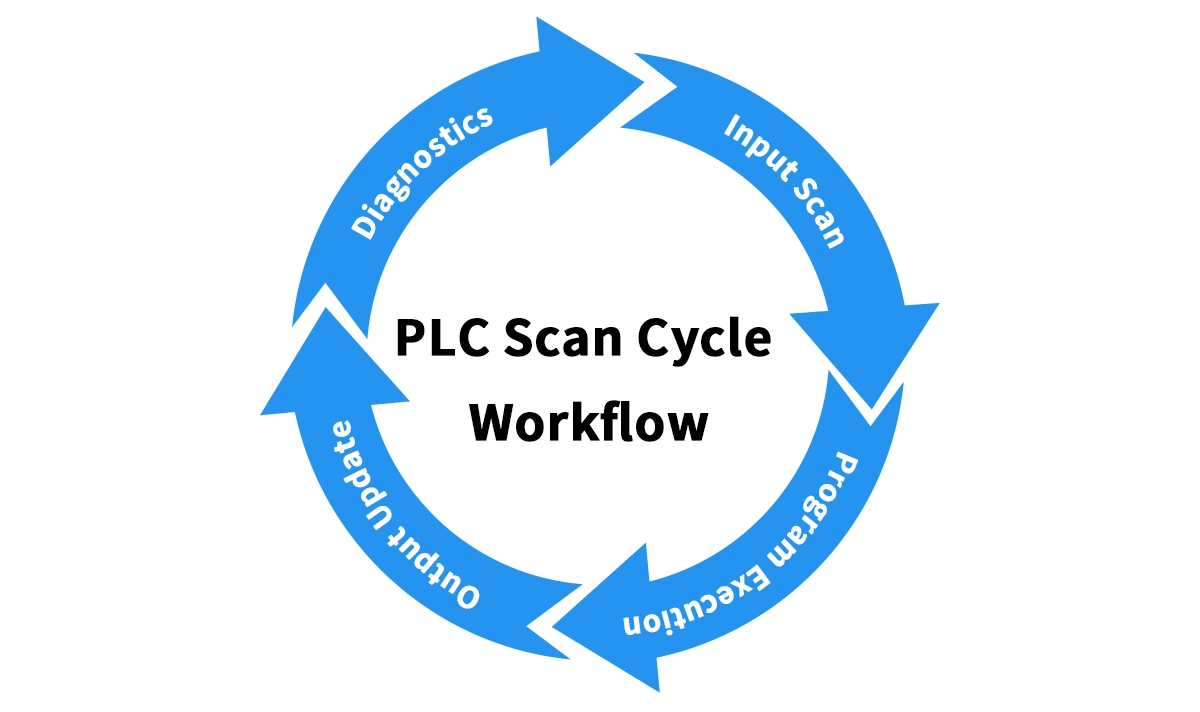

In simple terms, a PLC continuously performs a scan cycle consisting of:

Input Scan: Reading signals from sensors and switches.

Program Execution: Running user-defined control logic.

Output Update: Activating actuators, motors, or relays.

Diagnostics: Performing internal checks and communications.

▶ PLC Architecture and Key Components

A PLC system consists of several interconnected modules that work together to execute control tasks. Understanding its architecture helps engineers design more reliable systems and select compatible communication hardware such as LINK-PP’s RJ45 connectors, LAN transformers, and industrial optical transceivers.

♦ Core Components

CPU / Processor Module: Executes control programs and handles communication and diagnostics.

Power Supply: Converts incoming voltage to regulated DC power for internal modules.

Input Modules: Receive signals from sensors, switches, or meters (digital or analog).

Output Modules: Send control signals to actuators, relays, and motors.

Communication Modules: Enable data exchange with HMIs, SCADA systems, or industrial Ethernet networks such as EtherNet/IP, Modbus TCP, or Profinet.

Memory & Programming Interface: Store user logic and facilitate programming via software tools (IEC 61131-3 standard).

♦ Fixed vs. Modular Architecture

Fixed (Compact) PLC: Combines CPU, power, and I/O modules in one unit — compact and cost-effective for smaller systems.

Modular PLC: Uses separate plug-in modules for each function, offering scalability, flexibility, and easier maintenance for complex or expanding systems.

▶ Types and Classifications of PLCs

PLCs can be categorized based on their design and functionality:

Compact PLCs: Simple, all-in-one units ideal for small automation projects.

Modular PLCs: Rack-mounted, expandable systems suitable for large-scale industrial operations.

By Control Type: Discrete logic control, motion control, or process control, depending on application needs.

Modern PLCs support IEC 61131-3 programming languages, including:

Ladder Diagram (LD)

Function Block Diagram (FBD)

Structured Text (ST)

Sequential Function Chart (SFC)

Instruction List (IL)

▶ Benefits and Considerations

♦ Benefits

High Reliability: Designed for continuous operation in harsh environments.

Flexibility: Easily reprogrammed to adapt to process changes without rewiring.

Scalability: Modular PLCs allow expansion of I/O and communication modules.

Connectivity: Seamless integration with HMIs, SCADA, MES, and IIoT systems for real-time monitoring and control.

♦ Considerations

Initial Investment: Modular systems can be costly for small-scale applications.

Programming Skills: Complex automation tasks require professional programming expertise.

Compatibility: Selecting proper communication and I/O interfaces is critical for system reliability.

▶ LINK-PP Products in PLC Systems

As a global manufacturer of network magnetic components, RJ45 connectors, and industrial optical modules, LINK-PP provides key building blocks for PLC-based communication and automation infrastructure.

How LINK-PP Products Support PLC Networks

RJ45 Magnetic Connectors ensure stable Ethernet communication between PLCs, HMIs, and switches.

LAN Transformers enhance signal isolation and reduce electromagnetic interference.

Industrial SFP Optical Modules enable high-speed data transmission over long distances.

Shielded Connectors protect against noise and interference, maintaining reliable signal integrity in factory environments.

From PLC backplanes to Ethernet I/O modules and industrial gateways, LINK-PP’s connectivity solutions deliver robust performance for modern automation systems.

▶ Future Trends in PLC Technology

Edge Computing Integration: PLCs now feature onboard analytics for faster decision-making at the edge.

Industrial IoT (IIoT): Enhanced connectivity with smart sensors and cloud-based systems.

Modular Expansion: Hot-swappable modules improve system flexibility and uptime.

Cybersecurity: Hardware and network-level protection are becoming standard features.

AI-Assisted Programming: Emerging technologies support faster development and system optimization.

▶ Conclusion

The Programmable Logic Controller (PLC) remains the cornerstone of industrial automation — from controlling individual machines to orchestrating complex production lines.

For LINK-PP, understanding PLC architecture highlights the critical role of communication components such as connectors, transformers, and optical modules in ensuring reliable data transfer and system stability.

As factories become increasingly connected and intelligent, the reliability of the physical network layer — powered by LINK-PP — continues to define the performance and resilience of automation systems.

▶ FAQ

What is the main job of a PLC in automation?

A PLC helps control machines and processes. It can turn devices on or off. It reads sensors to check what is happening. It keeps your system working well.

What types of devices can you connect to a PLC?

You can connect sensors, switches, motors, lights, valves, and alarms.

Tip: Input modules get signals from sensors. Output modules send commands to devices.

What makes a PLC different from a regular computer?

A PLC is built to be tough. You use it in places like factories. It works well with lots of dust and shaking. It handles electrical noise better than a regular computer.

What programming languages can you use for PLCs?

You can use ladder logic, function block diagrams, structured text, and instruction lists.

Language | Common Use |

|---|---|

Ladder Logic | Simple controls |

Structured Text | Complex logic |