Introduction

Modern Programmable Logic Controllers (PLCs) are central to industrial automation, controlling machinery, production lines, and complex processes.

As automation systems evolve toward distributed architectures and smart factories, high-speed and long-distance communication between PLC modules, sensors, HMIs, and SCADA systems becomes essential.

Optical modules, such as SFP and SFP+ transceivers, play a critical role in providing reliable, high-performance connectivity for PLC networks. This article explores their applications, benefits, and practical scenarios in industrial automation.

1. Role of Optical Modules in PLC Systems

Traditional copper-based Ethernet connections may face challenges in industrial environments:

Electromagnetic interference (EMI) from motors, drives, and welding machines

Signal degradation over long distances

High-speed data transmission requirements for distributed control and monitoring

Optical modules overcome these limitations by providing fiber-optic links that deliver:

Immunity to EMI and crosstalk

Long-distance data transmission (up to tens of kilometers)

Low-latency, deterministic communication for real-time PLC control

2. Types of Optical Modules Used in PLC Networks

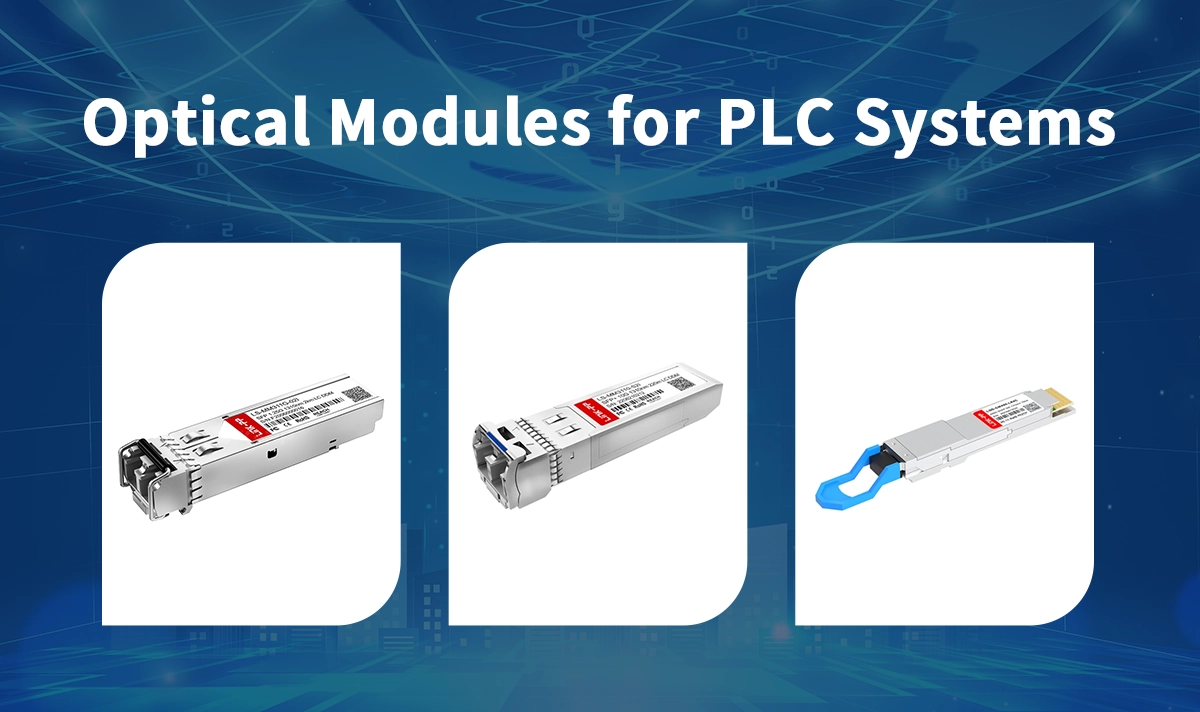

2.1 SFP (Small Form-factor Pluggable) Modules

Support 1G and 1.25G Ethernet speeds

Hot-swappable for easy maintenance and network expansion

Compatible with industrial switches and PLC communication ports

Ideal for connecting modular PLC racks across medium distances

2.2 SFP+ Modules

High-speed 10G Ethernet support for large-scale or high-performance PLC systems

Extended temperature operation for harsh industrial environments (-40°C to 85°C)

Compact form factor suitable for dense PLC switch panels and edge gateways

2.3 CPRI/eCPRI Compatible Modules

Enable real-time data communication for distributed PLC systems

Support integration with IIoT gateways and smart sensors

Low latency ensures precise control of synchronized processes

3. Integration Benefits of Optical Modules in PLC Systems

Benefit | Description |

|---|---|

Signal Integrity | Immune to EMI and voltage fluctuations, ensuring reliable data transmission. |

Long-Distance Communication | Fiber optic links extend PLC connectivity beyond copper limitations. |

High-Speed Data Transfer | Supports real-time control and monitoring for complex automation tasks. |

Scalability & Flexibility | Hot-swappable modules allow easy network expansion. |

Harsh Environment Compatibility | Industrial-grade optical modules operate reliably in extreme temperatures and vibration. |

4. Application Scenarios

Distributed PLC Systems: Fiber optic links connect remote I/O racks and edge devices to the main PLC CPU.

Smart Factory Networks: Optical modules integrate PLCs with industrial Ethernet switches, HMIs, SCADA, and IIoT gateways.

Robotics & Motion Control: High-speed, deterministic optical communication between PLCs and robotic controllers.

Edge Automation & Data Aggregation: Fiber modules transmit sensor data to edge or cloud systems for analytics and process optimization.

5. LINK-PP Optical Modules for PLC Systems

LINK-PP provides industrial-grade optical modules optimized for PLC networks:

SFP and SFP+ transceivers supporting 1G/10G Ethernet and extended temperature ranges.

CPRI/eCPRI-compatible modules for distributed automation and real-time data transmission.

Compact, low-power designs for integration in PLC communication racks, industrial switches, and edge devices.

High reliability ensures continuous operation in electrically noisy and harsh industrial environments.

By integrating LINK-PP fiber transceivers, PLC systems achieve enhanced network performance, extended reach, and future-proof connectivity for modern industrial automation.

6. Conclusion

Optical modules are transforming PLC systems by enabling high-speed, long-distance, and interference-free communication. They are essential for distributed PLC architectures, IIoT integration, and smart factory deployments.

LINK-PP SFP modules provide the performance, durability, and scalability needed to maintain reliable PLC network connectivity, making them a vital component in modern industrial automation systems.