In the intricate world of networking, choosing the right transceiver is crucial for performance, density, and cost. Two historic yet often confused players in this space are SFF and GBIC. While both paved the way for modern fiber optics, they serve distinct purposes and are built with fundamentally different philosophies.

Understanding the difference between a Solder-Type SFF and a GBIC is more than a history lesson; it's about making informed decisions for existing infrastructure and appreciating the evolution of network technology. Let's dive in!

✅ SFF vs GBIC: A Head-to-Head Comparison

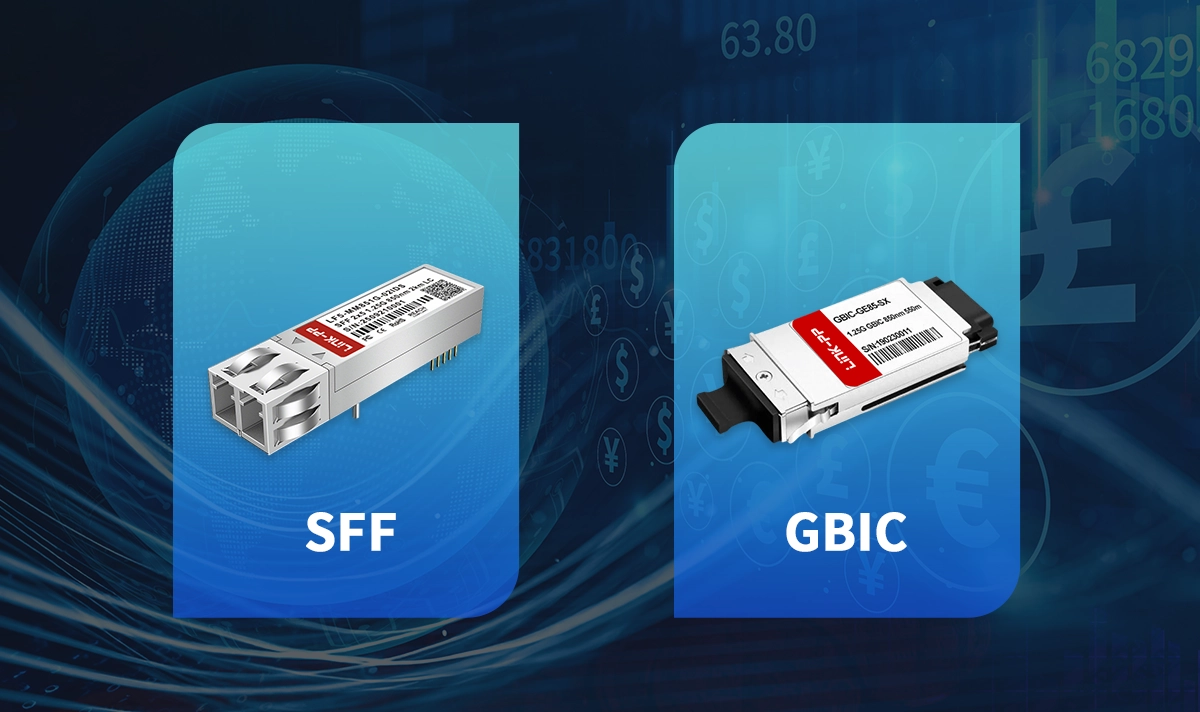

First, let's clear a major point of confusion. In this context, SFF stands for Small Form-Factor, specifically referring to the solderable, non-pluggable transceivers defined by the SFF Committee. This is not the same as the later, hot-pluggable SFP. The key difference is that SFF modules are permanently soldered onto the host board, while GBICs and SFPs are pluggable.

The following table outlines the core differences:

Feature | GBIC (Gigabit Interface Converter) | SFF (Small Form-Factor) |

|---|---|---|

Form Factor | Larger, pluggable module | Very small, solderable module |

Hot-Swappable | Yes ✅ | No ❌ (Permanently attached) |

Port Density | Low (1 port per module) | Very High (Multiple per line card) |

Primary Use Case | Switches, Routers, where flexibility is key | Fixed-function devices, embedded systems |

Maintenance | Easy to replace without powering down | Requires soldering, difficult to replace |

Cost Consideration | Higher per-port cost, but flexible | Lower per-port cost, but fixed |

Example Application | Enterprise network switches | Optical Network Terminals (ONTs), media converters |

✅ Deep Dive: The GBIC (Gigabit Interface Converter)

The GBIC was a revolutionary step forward. Its defining feature was hot-swappability. Network administrators could easily upgrade, configure, or repair a fiber link by simply unplugging one GBIC and inserting another, without disrupting the entire system.

Pros:

Flexibility: Supported a wide range of fiber types (single-mode, multi-mode) and distances simply by swapping the module.

Ease of Use: Simplified inventory management and reduced downtime.

Interoperability: Standardized form factor allowed for multi-vendor solutions.

Cons:

Size: Its large size limited port density on switches and routers.

Cost: Generally more expensive per port than fixed alternatives.

✅ Deep Dive: The Solder-Type SFF Module

The SFF module was designed with a different goal: maximize port density and reduce cost. By soldering the transceiver directly onto the motherboard, manufacturers saved space and cost, eliminating the need for a bulky cage and latch assembly.

⚠️ Important Note: This is the critical distinction. These SFF modules are not user-replaceable. They are a permanent part of the device's hardware. You will commonly find them in consumer-grade or fixed-configuration equipment like:

Optical Network Terminals (ONTs) from ISPs

Certain media converters

Embedded telecom systems

This is where choosing a reliable supplier from the start is paramount. For instance, a high-quality SFF module soldered into an ONT ensures stable, long-term performance without the need for replacement.

✅ GBIC vs SFF: Which One is Right for You?

The choice is typically made by the hardware manufacturer, but understanding it helps you choose the right equipment.

Choose equipment with GBICs (or their modern successor, the SFP) if you need flexibility, scalability, and ease of maintenance. This is ideal for enterprise data centers and networks where technology needs may change.

Equipment with soldered SFF modules is designed for cost-effective, high-density, and fixed-function applications. You "choose" it by selecting a device that meets your long-term speed and distance requirements upfront, as you cannot change it later.

✅ The Modern Landscape and The LINK-PP Advantage

Today, the GBIC is largely obsolete, replaced by its smaller sibling, the SFP (Small Form-factor Pluggable). However, solder-type SFF modules are still widely used in specific OEM applications.

Whether you're dealing with legacy GBIC equipment or sourcing devices with integrated SFF modules, quality is non-negotiable. This is where LINK-PP excels.

LINK-PP provides reliable, high-performance optical components that meet strict standards. For your pluggable needs, the LINK-PP GBIC offers flawless compatibility and stable data transmission. For manufacturers looking to integrate solder-type modules, LINK-PP offers a range of dependable SFF options designed for longevity and performance.

> 🛠️ Explore LINK-PP's full range of compatible and high-quality optical transceivers to find the perfect solution for your network's legacy and modern needs. [Discover LINK-PP Modules Today!]

✅ Conclusion

The GBIC vs. SFF debate is a classic example of a trade-off between flexibility and density/cost. The pluggable GBIC brought unparalleled ease of use to networks, while the solder-type SFF enabled the compact, affordable devices we often use at the edge of the network. Knowing the difference empowers you to better understand your network's architecture and make smarter purchasing decisions for years to come.