In the vast ecosystem of fiber optic transceivers, pluggable modules like SFP, QSFP, and OSFP get most of the attention. However, for many mission-critical applications where reliability, size, and cost are paramount, a different solution shines: the SFF (Small Form-Factor) Optical Module.

Unlike their pluggable cousins, SFF modules are designed to be permanently soldered onto a host board (PCB). This fixed-design approach makes them the invisible engine powering a massive range of network equipment you use every day.

➤ SFF vs. SFP: Clearing the Confusion

It's the most common point of confusion. While both share the "Small Form-Factor" name, they serve fundamentally different purposes.

SFF (Small Form-Factor): Refers to a fixed or soldered optical transceiver. It is a compact component permanently attached to the device's main board. It is not hot-pluggable.

SFP (Small Form-factor Pluggable): Refers to a hot-pluggable transceiver that inserts into a dedicated cage/port on a switch or router. SFP is a specific implementation of a small form-factor that prioritizes flexibility.

The key difference is pluggability. SFF is for embedded, permanent design; SFP is for field-replaceable flexibility.

➤ Why Choose a Soldered SFF Optical Module?

Why would a manufacturer choose a fixed SFF module over a pluggable one? The advantages are significant for specific use cases:

Enhanced Reliability: With no moving parts, connectors, or cages, the soldered connection is far more robust against vibration, shock, and physical wear, leading to a higher mean time between failures (MTBF).

Superior Density: By eliminating the large port cage, SFF modules allow for an even higher port density on a single PCB, perfect for compact hardware.

Cost-Effectiveness: Removing the expensive cage, latch, and connector significantly reduces the total bill of materials (BOM) cost for high-volume production.

Thermal Performance: Direct soldering to the board often allows for more efficient heat dissipation away from the laser.

➤ SFF vs. Pluggable Modules: Application Comparison

The following table illustrates how the choice between SFF and pluggable forms is driven by the application's core requirements.

Feature / Application | SFF (Soldered) | SFP (Pluggable) |

|---|---|---|

Primary Use | Embedded, fixed configuration within equipment | Field-replaceable ports on networking gear |

Key Advantage | Reliability, Density, Cost | Flexibility, Interoperability, Upgradability |

Typical Hardware | Network Interface Cards (NICs), Router/Switch Line Cards, GPON ONTs/OLTs, Embedded Systems | Network Switches, Routers, Media Converters |

Hot-Swappable | ❌ No | ✅ Yes |

Unit Cost | Lower | Higher |

➤ Key Applications of SFF Optical Modules

You won't see them, but SFF modules are everywhere inside:

Network Interface Cards (NICs): High-performance server NICs often use soldered SFF optics to provide reliable fiber connectivity.

Fiber Optic Transceivers for GPON/XPON: The Optical Network Terminals (ONTs) at your home or office and the Optical Line Terminals (OLTs) at the provider's central office heavily rely on SFF technology.

Router and Switch Line Cards: Many large chassis-based systems use line cards with embedded SFF optics for high-density uplinks.

Industrial and Embedded Networking: Equipment designed for harsh environments favors the rugged reliability of soldered optics.

For these embedded optical transceiver solutions, performance consistency is non-negotiable.

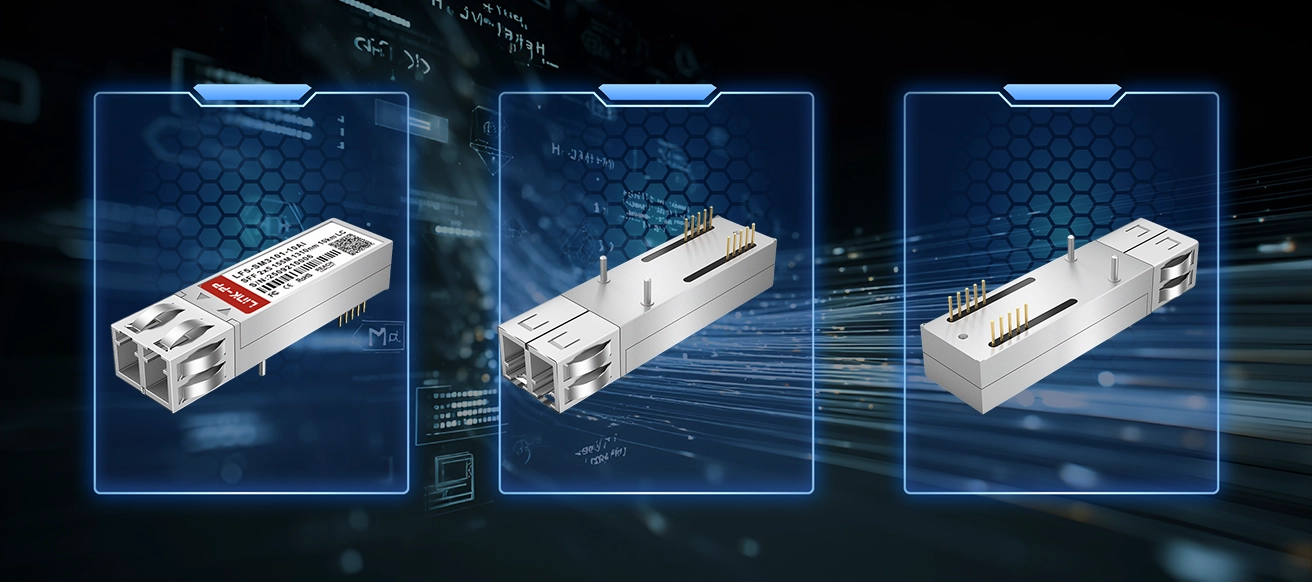

➤ LINK-PP: Delivering Reliability in Embedded SFF Optics

For OEMs designing equipment that demands uncompromising reliability, choosing the right component supplier is critical. LINK-PP specializes in manufacturing high-quality, standards-compliant SFF optical modules that are engineered for seamless integration into your products.

A prime example of our expertise is the LINK-PP LF5-SC3501-40IDL. This compact, solderable SFF module is ideal for bidirectional fiber applications, transmitting and receiving signals on a single fiber strand for cost-effective fiber to the home (FTTH) deployments and other single-fiber bidirectional links.

For multi-gigabit embedded applications, our LINK-PP LF5-SM3101-10AI model provides a robust 1G Ethernet solution over single-mode fiber, perfect for soldering onto high-end network adapters and storage controllers, ensuring low-latency network performance.

➤ Conclusion: The Hidden Backbone of Connectivity

While they may lack the glamour of hot-swappable modules, SFF optical modules are the workhorses of the networking world. Their soldered-in-place design offers an unbeatable combination of reliability, density, and value for fixed-configuration hardware. Understanding this distinction is key for anyone involved in network hardware design and manufacturing.

Designing reliable, high-density network hardware? 🤝

Partner with LINK-PP for your embedded optical needs. Our SFF optical modules are built for performance and longevity. Contact our engineering team today to discuss integration options or request samples for your next-generation product design.