1 Form Factor & Space Utilization

Single-Port:

One connector per housing. Ideal for devices with limited port needs or isolated signal environments. Requires more PCB space for multiple Ethernet lines.Multi-Port:

Multiple RJ45 jacks grouped in one module (e.g., 1x4, 2x2, 2x8). Significantly reduces board space and enables high-density Ethernet designs.

2. Design Complexity

Single-Port:

Simpler to route, lower EMI concerns, often used in industrial or consumer devices with low Ethernet traffic.Multi-Port:

Complex internal routing. EMI shielding and crosstalk management are more critical. Ideal for switches, routers, servers.

3. LED & Magnetic Integration

Both types may include integrated magnetics, PoE support, and LED indicators. However:

Multi-Port modules often offer ganged LED or centralized magnetics for all ports.

Single-Port units allow more customization per port.

4. Assembly & Manufacturing

Multi-Port reduces pick-and-place operations and BOM count, improving manufacturing efficiency.

Single-Port may be more flexible in modular assembly or when layout needs are irregular.

5. Typical Use Cases

Application | Recommended Connector Type |

|---|---|

Industrial Devices | Single-Port |

Network Switches | Multi-Port (e.g., 2x8 or 1x6) |

Consumer Electronics | Single-Port |

Enterprise Routers | Multi-Port |

Test Equipment | Single-Port or mixed |

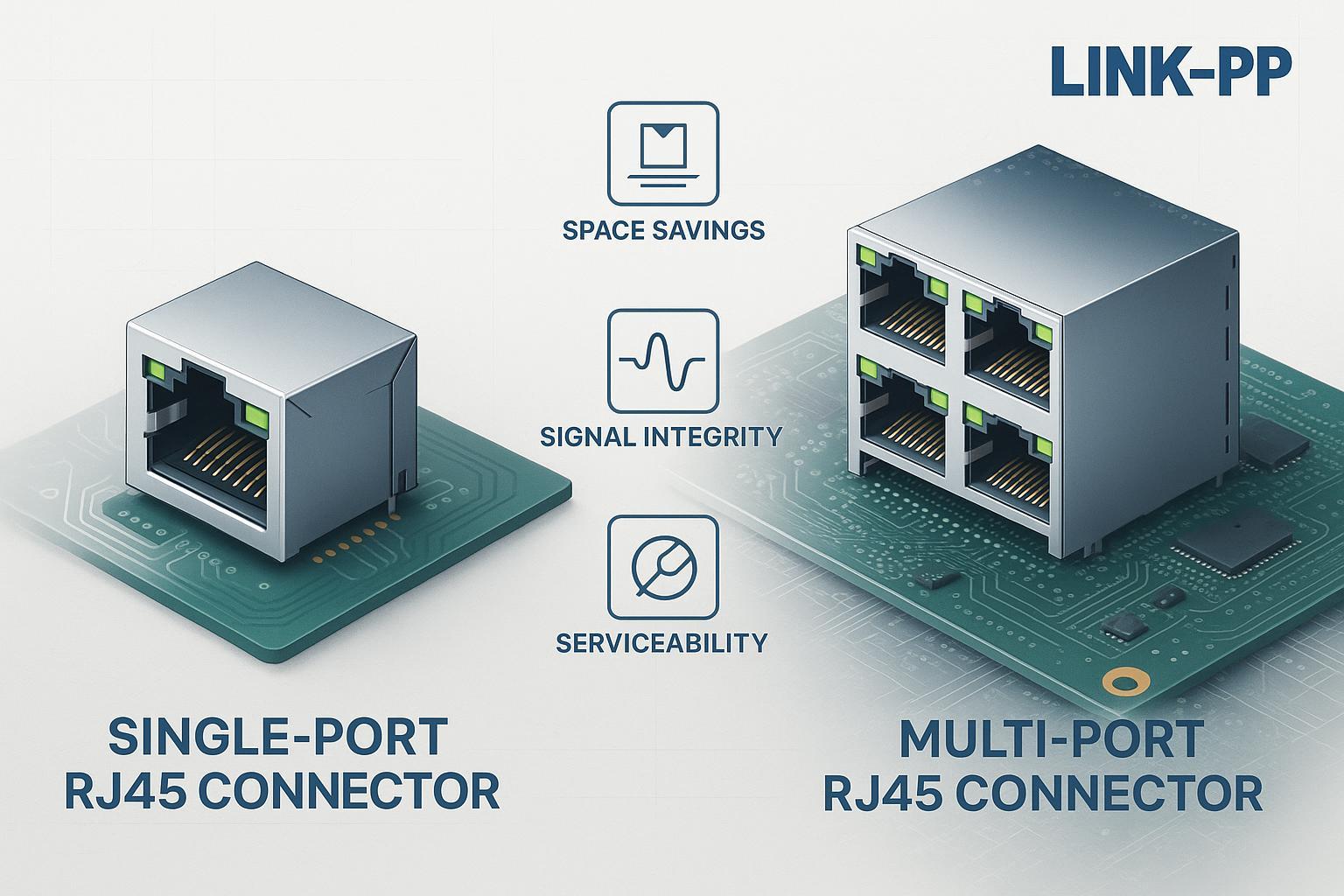

Application Scenarios (Deployment Flexibility)

Single-Port:

Datacenter uplinks, SAN/fail-safe controls, field/utility panels, telco edge, devices requiring extreme reliability and fast repair.

Multi-Port:

Switches/routers/servers in rackmount/campus, factory-floor and enterprise backbone, high volume or modular chassis.

Mixed strategy:

Common best practice: Use single-port for redundant uplinks/critical channels, multi-port for aggregation or user access—optimizes both serviceability and density.

6. Cost Consideration

Multi-Port modules generally offer a better cost-per-port ratio but may be more expensive as individual components.

Single-Port is cost-effective in small volume or when few ports are needed.

Scenario-Based Recommendations

Choose Single-Port When:

Critical links must be field-replaceable in under 5 minutes (e.g., telco uplink, server failover)

EMI/crosstalk pose reliability risks (industrial/process control, medical)

Deployment spans across legacy or multi-vendor boards, where certified compatibility is vital

Choose Multi-Port When:

Board space constraint trumps per-port isolation (campus/core rack gear, edge switches)

Cost-per-port and rapid volume deployment are paramount

Service access is less frequent/less critical or board-level swap is acceptable

Optimize with LINK-PP:

Leverage LINK-PP for certified compatibility, advanced PoE/surge options, special density layouts, or rapid sample-to-order turnaround at scale.

Combine single-port for uplink/critical, multi-port for aggregation: best of both worlds.

LINK-PP Solution Highlights

LINK-PP offers both single and multi-port RJ45 connectors with:

Shielded/Unshielded options

Integrated Magnetics

PoE/PoE+ compatibility

Industrial-grade reliability

LINK-PP: B2B Innovation, Compatibility, and Support

Certified cross-brand compatibility: One of the only vendors assuring fit with Pulse, Molex, Bel, Cisco, and more

Advanced PoE/surge: Up to IEEE 802.3bt; robust TVS, filter, and EMI management

Free Samples & Tech Consultation: Request free samples or engineering support on your next project

Global fulfillment: MOQ = 1, custom specs, rapid delivery, documentation support

Curious which connector truly fits your deployment? Connect with LINK-PP senior engineers for a free sample or technical consultation on your next project.

Who Should Read This?

OEM/network hardware engineers choosing RJ45 layout for new board designs.

B2B procurement and technical teams evaluating supply, reliability, and lifetime serviceability.

Data center/network architects needing to balance space, density, and critical path redundancy.

Project leads considering LINK-PP for volume deployments or custom specs.