In the world of fiber optic communications, where high-speed data zips across continents in the blink of an eye, there are unsung heroes working behind the scenes. One such critical component is the Optical Splitter. If you've ever wondered how a single fiber from your internet service provider can deliver service to an entire neighborhood or apartment building, you've wondered about the magic of optical splitters.

This guide will demystify this pivotal passive device, exploring its types, working principles, and how it seamlessly integrates with optical transceivers to bring high-speed internet to your doorstep.

📄 What is an Optical Splitter?

An Optical Splitter, also known as a beam splitter, is a passive optical device that divides a single input optical signal into two or more output signals. Conversely, it can also combine multiple signals into one. Its primary role is in Passive Optical Networks (PON), which are the foundation of most Fiber-to-the-Home (FTTH) deployments.

Think of it as a traffic roundabout for light signals. A single highway (input fiber) enters, and the roundabout (splitter) distributes the cars (light photons) efficiently onto several exit roads (output fibers), all without any active power source.

📄 How Does an Optical Splitter Work?

The working principle is based on the fundamental physics of light. Light, traveling through the core of a fiber optic cable, can be split by precisely fusing and tapering fibers together. This creates a region where the light signal is coupled and redistributed among the output fibers.

The key performance metrics are:

Insertion Loss: The natural attenuation of the signal power due to the splitting process.

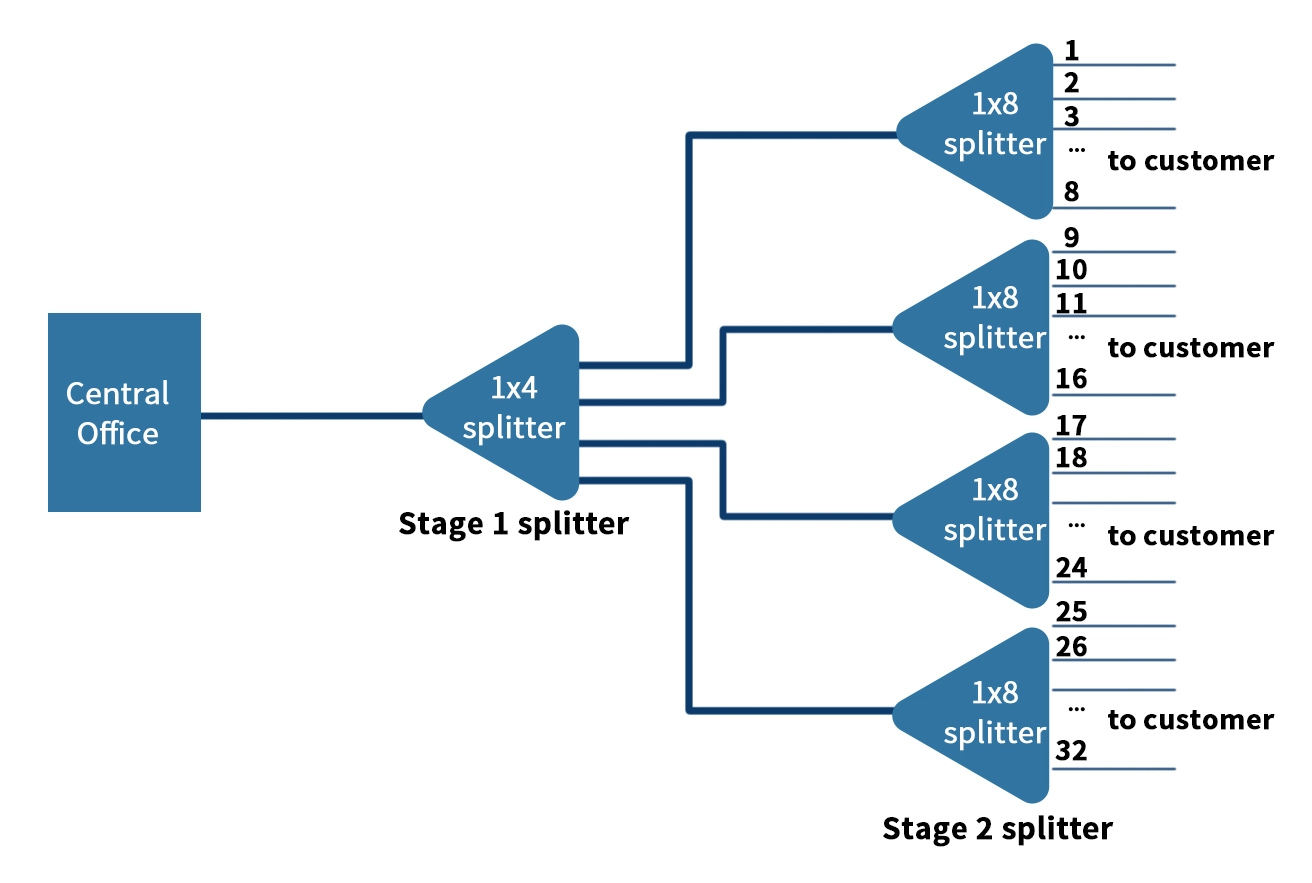

Split Ratio: The ratio of how the input power is distributed among the outputs (e.g., 1x4, 1x8, 1x32).

Uniformity: How consistent the output power is across all the output ports.

A higher split ratio (like 1x64) means the signal is divided among more users, which increases the insertion loss and can limit the overall reach of the network.

📄 FBT vs. PLC Splitters: Choosing the Right Type

There are two main manufacturing technologies for optical splitters, each with its own advantages and ideal use cases. The choice between them depends on your application requirements.

Feature | Fused Biconical Taper (FBT) Splitter | Planar Lightwave Circuit (PLC) Splitter |

|---|---|---|

Technology | Fibers are fused and tapered together | Uses a silica glass waveguide circuit |

Wavelength | Best for 850nm, 1310nm, 1550nm | Works across full spectrum (1260nm - 1650nm) |

Split Ratio | Up to 1x4 typically, higher possible | Compact size, can go up to 1x64 easily |

Size/Form Factor | Larger, housed in stainless tube | Compact, housed in box or module |

Cost | Lower cost | Higher cost, but price has decreased |

Best For | Smaller splits, less critical applications | Large-scale FTTH/PON deployments, data centers |

For most modern FTTH applications, PLC splitters are the preferred choice due to their compact size, reliability, and better performance across a wider range of wavelengths.

📄 The Critical Link: Optical Splitters and Optical Modules

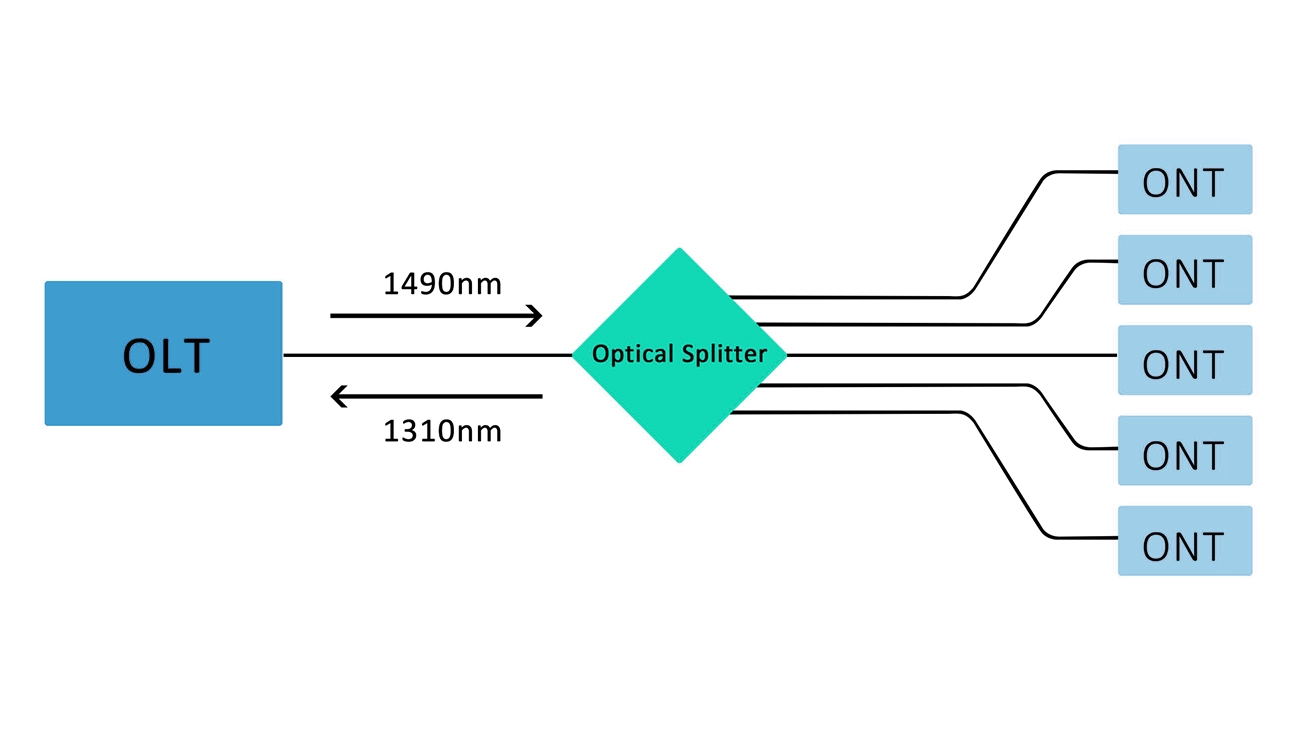

This is where the magic of a full optical network comes together. An optical splitter is a passive device, but it doesn't work alone. It relies on active equipment at both ends of the fiber link: the Optical Line Terminal (OLT) at the provider's central office and an Optical Network Unit (ONT) at your home.

The optical transceiver module (like an SFP, SFP+, or XFP module) in the OLT is the laser source that generates the initial light signal. This high-power signal is transmitted down the single fiber. When it reaches the optical splitter, the signal is divided and sent to multiple ONUs.

The performance of the optical transceiver is paramount. It must have enough output power to ensure that even after being split (and suffering significant insertion loss), the signal reaching the farthest ONU is still strong enough to be detected. This is a key consideration for network designers looking for reliable PON equipment.

For instance, to ensure stable connectivity in a 1x32 split scenario, you would need a high-quality OLT transceiver. This is where a vendor like LINK-PP excels, providing highly reliable and consistent optical modules designed to work perfectly in high-split-ratio environments.

📄 Where are Optical Splitters Used?

Fiber-to-the-Home (FTTH / FTTx): The most common application, distributing signals to multiple subscribers.

Passive Optical Networks (PON): Like GPON, EPON, and XGS-PON architectures.

CATV Systems: Distributing video signals over fiber.

Fiber Optic Test Equipment: For monitoring and measuring optical power.

Data Centers: For signal distribution in certain internal links.

📄 Ensuring Network Success: The LINK-PP Advantage

Designing and maintaining a robust optical network requires high-quality components at every stage. From the central office to the customer premises, every connection matters. While the optical splitter handles the distribution, the optical transceivers are the tireless engines powering the data.

For network engineers and ISPs, choosing a trusted partner for both passive and active components is crucial. LINK-PP offers a comprehensive range of high-performance optical PON modules, including GPON ONU SFP modules and XGS-PON OLT SFP+ transceivers, engineered for low power consumption and high stability. Paired with reliable PLC splitters, a LINK-PP 100G QSFP28 solution can form the backbone of a next-generation data center spine, while their PON modules enable last-mile connectivity.

Whether you're rolling out a new FTTH service or upgrading an existing network, ensuring compatibility between your splitters and transceivers is key to minimizing latency and maximizing uptime.

Ready to optimize your optical network? ➡️ Explore LINK-PP's range of reliable optical transceivers and discover the perfect solution for your FTTH, data center, or enterprise application. [📌 LINK-PP Product Page]

📄 FAQ

What is the main job of a beamsplitter?

A beamsplitter splits one light beam into two parts. You use it to send light in different directions. This helps you share light between sensors, cameras, or other tools.

What types of coatings do splitters use?

You find two main coatings: dielectric and metallic. Dielectric coatings work well with lasers and high power. Metallic coatings cover a wide range of colors. Always check which coating matches your needs.

What happens if you use the wrong splitter?

If you pick the wrong splitter, you may lose light or get poor results. The beam might not split as you want. You could also damage your equipment. Always match the splitter to your setup.

What makes dichroic beamsplitters special?

Dichroic beamsplitters split light by color. You use them when you want to separate different wavelengths. These splitters help you control which color goes where in your system.

What should you check before installing a splitter?

You should check the size, shape, and mounting needs. Make sure the splitter fits your setup. Look at the datasheet for details. This helps you avoid problems during installation.