In the intricate world of fiber optics, where every photon counts, passive components like splitters play a monumental role. They are the unsung heroes silently dividing optical signals to deliver data to multiple endpoints, making technologies like Fiber-to-the-Home (FTTH) possible. But when it comes to choosing a splitter, the debate often narrows down to two main technologies: FBT (Fused Biconical Taper) and PLC (Planar Lightwave Circuit).

Understanding the difference is crucial for building a efficient, scalable, and cost-effective network. This guide will demystify these two technologies, compare them head-to-head, and help you make an informed decision. Let's dive in!

📜 Key Takeaways

FBT Splitter works well for small networks and easy setups. It costs less and has flexible splitting ratios.

PLC Splitter is best for big networks. It gives high accuracy and can support many outputs. This makes it good for complex needs.

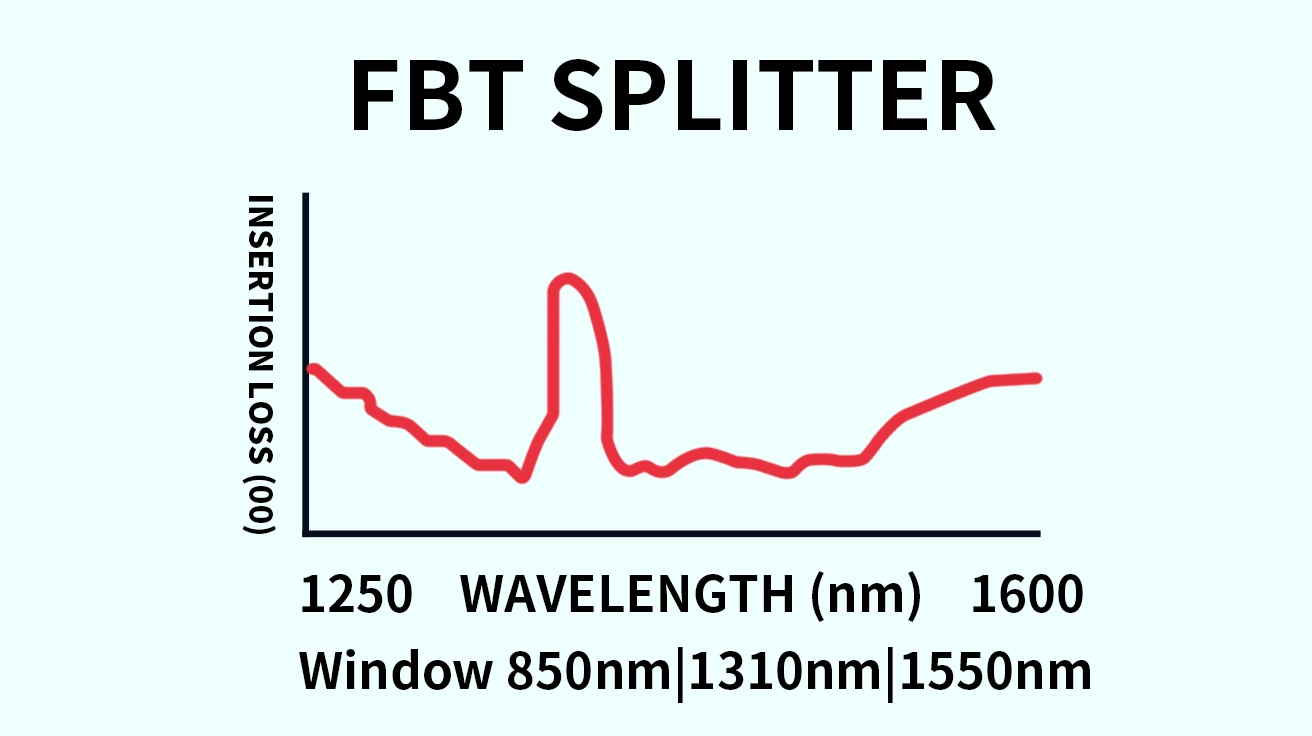

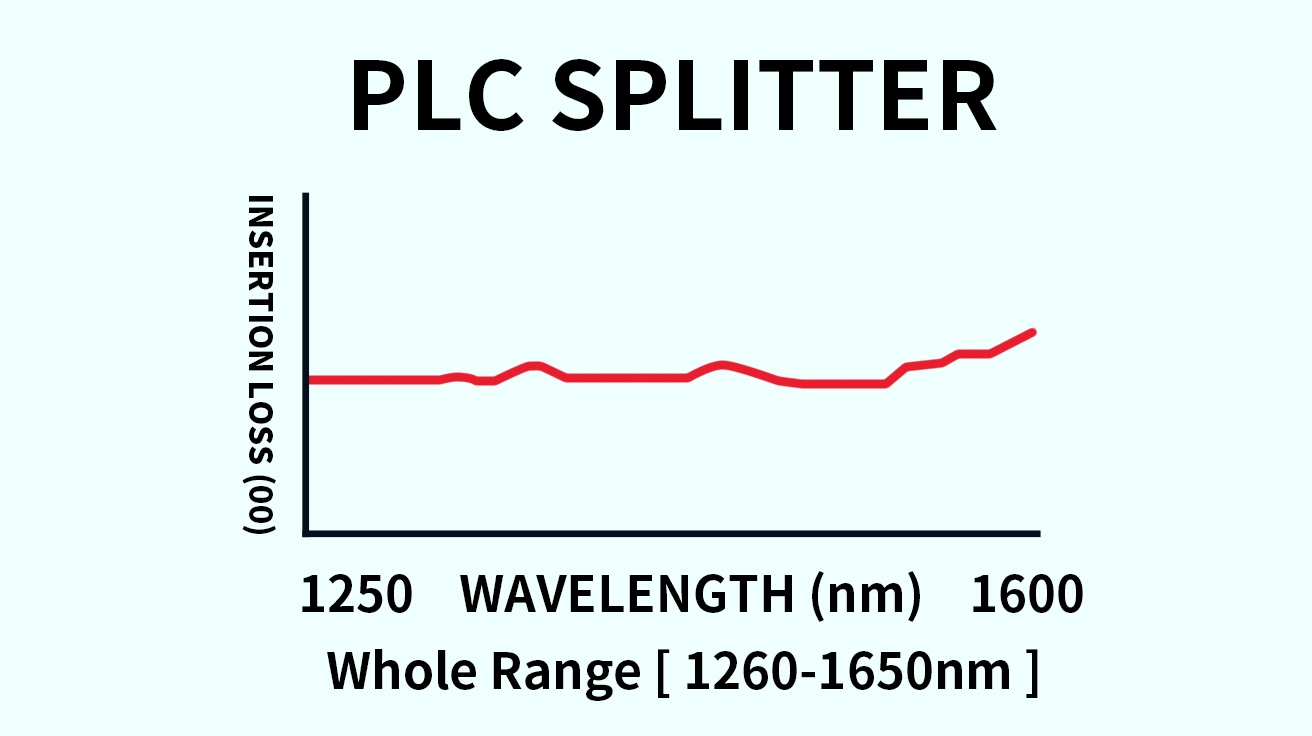

Think about the wavelength range when picking a splitter. PLC Splitter supports a wider range. This gives you more options.

Reliability is important. PLC Splitter works well in different temperatures. FBT Splitter may not work well in very hot or cold places.

Look at your network size, budget, and space before you choose a splitter. This helps you pick the best one for your needs.

📜 What is an FBT Splitter?

FBT is a more traditional technology. The process involves fusing two or more optical fibers together while applying a tapered stretch. This creates a coupling region where the incoming light signal is split between the output fibers.

Key Characteristics of FBT Splitters:

Cost-Effective for Low Splits: They are generally cheaper to manufacture for configurations with a lower number of splits, such as 1x2 or 1x4.

Wavelength Sensitivity: Traditional FBT splitters are optimized for specific wavelengths (commonly 1310nm, 1490nm, and 1550nm). Using them outside their designated window can lead to higher losses.

Temperature Sensitivity: Their performance can be more susceptible to fluctuations in temperature, making them less ideal for harsh outdoor environments without protective housing.

Size: As the split count increases (e.g., 1x8, 1x16), the device becomes larger and more cumbersome.

📜 What is a PLC Splitter?

PLC represents a more advanced, integrated approach. This technology uses lithography to etch a light-routing circuit onto a silica glass chip, similar to how electronic circuits are printed on a semiconductor. This chip provides a precise and reliable way to split the light signal.

Key Characteristics of PLC Splitters:

High Uniformity & Stability: The manufacturing process ensures that the signal is split with exceptional uniformity across all output channels. They are also highly stable across a wide temperature range (-40°C to 85°C).

Broad Wavelength Support: PLC splitters operate seamlessly across the full spectrum from 1260nm to 1650nm, making them perfect for tri-play services (data, voice, video) and wavelength division multiplexing (WDM) applications.

Compact Size: The chip-based design allows for very high split ratios (up to 1x64) in a remarkably small form factor, ideal for space-constrained modules and distribution boxes.

Higher Initial Cost: The sophisticated manufacturing process typically makes PLC splitters more expensive for lower split counts.

📜 FBT vs PLC: A Detailed Comparison Table

Here’s a quick-glance table to highlight the core differences.

Feature | FBT Splitter | PLC Splitter | Winner for... |

|---|---|---|---|

Technology | Fused Fibers | Waveguide Chip | N/A |

Split Ratio | Up to 1x4 (common), up to 1x32 (less uniform) | Up to 1x64 uniformly | High, Uniform Splits: PLC |

Wavelength Range | Narrowband (e.g., 1310/1550nm) | Broadband (1260nm - 1650nm) | Flexibility & WDM: PLC |

Uniformity | Moderate to Low (can vary between ports) | Very High (<1.5dB typical) | Signal Consistency: PLC |

Size/Form Factor | Larger for high splits | Compact, high-density | Space-Saving: PLC |

Temperature Stability | Good (0°C to 60°C) | Excellent (-40°C to 85°C) | Harsh Environments: PLC |

Cost | Lower for 1x2, 1x4 | Higher for low splits, competitive for high splits | Budget-Conscious (Low Split): FBT |

Best Application | Simple, cost-sensitive projects with low splits | High-density FTTH, PON networks, demanding environments | Future-Proof Networks: PLC |

📜 The Critical Link: How Your Optical Transceiver Choice Matters

A discussion about splitters is incomplete without mentioning optical transceivers. These active devices are the endpoints that convert electrical signals to light and vice versa. The performance of your entire link depends on the harmony between the transceiver and the splitter.

For instance, a GPON optical transceiver at the OLT (Central Office) must work flawlessly with the 1x32 or 1x64 PLC splitters in the field. The splitter's insertion loss directly impacts the link budget of your optical transceiver module. Choosing a low-quality splitter can cause signal degradation, leading to network downtime and increased bit error rates (BER).

This is where partnering with a reliable supplier like LINK-PP becomes a strategic advantage. LINK-PP ensures that their components, from splitters to a wide range of compatible optical transceivers, are engineered to work together seamlessly. For example, when deploying a high-split FTTH network, using a LINK-PP PLC Splitter alongside a compatible LINK-PP SFP transceiver guarantees optimal performance and simplifies troubleshooting.

A great choice for such applications is the 1x32 PLC splitter, which offers outstanding uniformity and reliability. When paired with a LINK-PP GPON SFP module, you create a robust and efficient link, perfectly suited for ensuring stable fiber optic network performance in modern passive optical networks (PON).

📜 How to Choose the Right Splitter for Your Project

So, which one should you choose? The answer lies in your specific requirements.

Choose an FBT Splitter if:

Your project has a very tight budget.

You only need a 1x2 or 1x4 split.

The application is for a simple, indoor, and temperature-controlled environment.

Choose a PLC Splitter if:

You need a split ratio of 1x8 or higher.

Your network requires high reliability and signal uniformity (e.g., FTTH).

The operating environment has wide temperature variations.

You are using multiple wavelengths or planning for future network upgrades.

For most modern applications, especially those involving fiber optic installation and FTTH network design, PLC is the recommended and future-proof technology.

📜 Conclusion & Next Steps

While FBT splitters have their place in niche, low-cost scenarios, PLC splitters are the undisputed champion for modern, high-performance optical networks. Their superior uniformity, compact size, broad wavelength support, and excellent stability make them the intelligent choice for building scalable and reliable infrastructure.

📜 FAQ

What is the main difference between FBT Splitter and PLC Splitter?

You see FBT Splitter uses fused fiber technology. PLC Splitter uses a chip to split light. FBT works best for small networks. PLC fits large, complex setups.

Which splitter is better for large networks?

You should choose PLC Splitter for large networks. It supports more outputs and gives you even signal strength. FBT Splitter works well for small, simple networks.

Does temperature affect both splitters the same way?

You notice FBT Splitter can lose performance in extreme temperatures. PLC Splitter stays stable in hot or cold places. PLC is better for harsh environments.

Can I use both splitters for different wavelengths?

You get narrow wavelength support with FBT Splitter. PLC Splitter supports a wide range of wavelengths. PLC gives you more flexibility for future upgrades.

Which splitter saves more space in my setup?

You save space with PLC Splitter. It has a compact design and fits tight areas. FBT Splitter is larger and needs more room.