Selecting the right industrial SFP or SFP+ optical transceiver is a technical and procurement decision that affects link reliability, maintainability, and total cost of ownership. This guide consolidates authoritative guidance and practical criteria—compatibility, data rate and form factor, fiber & wavelength, link budget, environmental ruggedness, digital diagnostics (DDM), and vendor quality—so network engineers and procurement teams can choose with confidence.

🔹 1) Compatibility With Host Devices and MSA Standards

Compatibility is the first requirement when selecting an industrial SFP. Although SFP modules follow MSA (Multi-Source Agreement) design rules, each switch, router, or industrial controller has a specific compatibility matrix.

Key points

Confirm that the SFP model is listed as compatible with the intended switch or industrial Ethernet device.

Ensure compliance with the correct form factor: SFP for 1G, SFP+ for 10G, SFP28 for 25G, etc.

When using third-party optics, verify that the firmware and monitoring functions operate as expected.

For large deployments, test sample units in real hardware environments before approval.

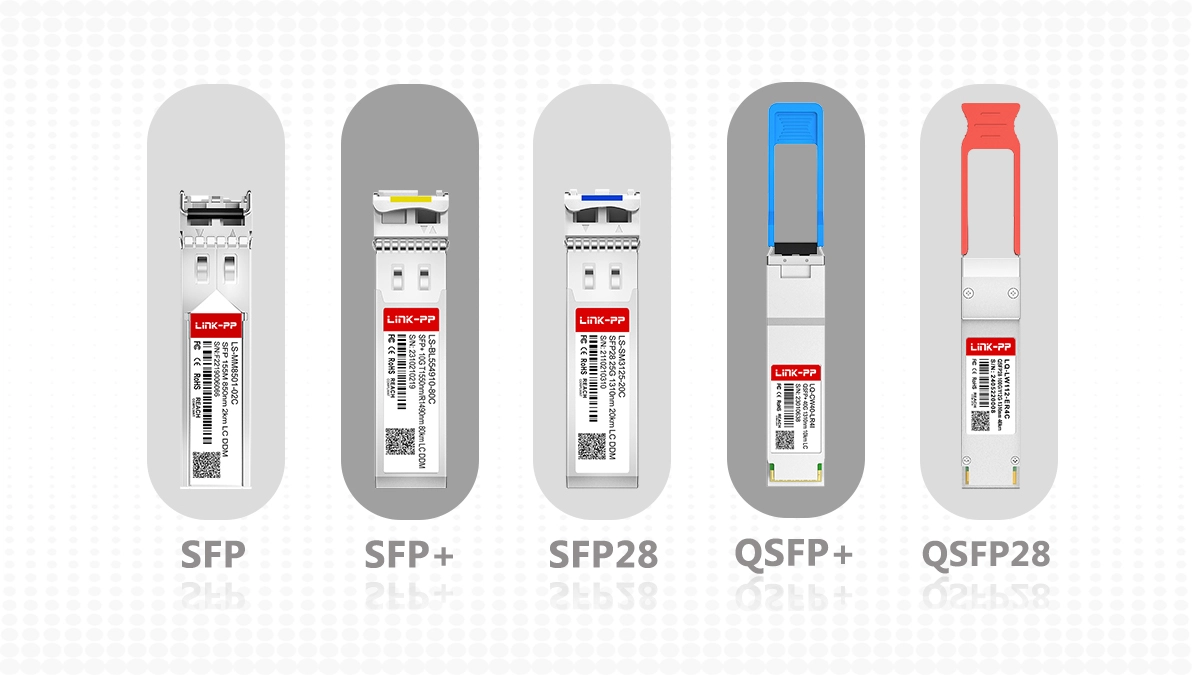

🔹 2) Data Rate, Port Type, and Form Factor

Matching the transceiver’s data rate to the host port is essential to avoid negotiation failures or unstable links.

What to check

1G SFP vs 10G SFP+ vs 25G SFP28 — identical mechanical design, different electrical specifications.

Not all SFP+ ports support 1G fallback; check the device’s spec sheet.

For scalable networks, consider hardware platforms that support mixed-rate optics.

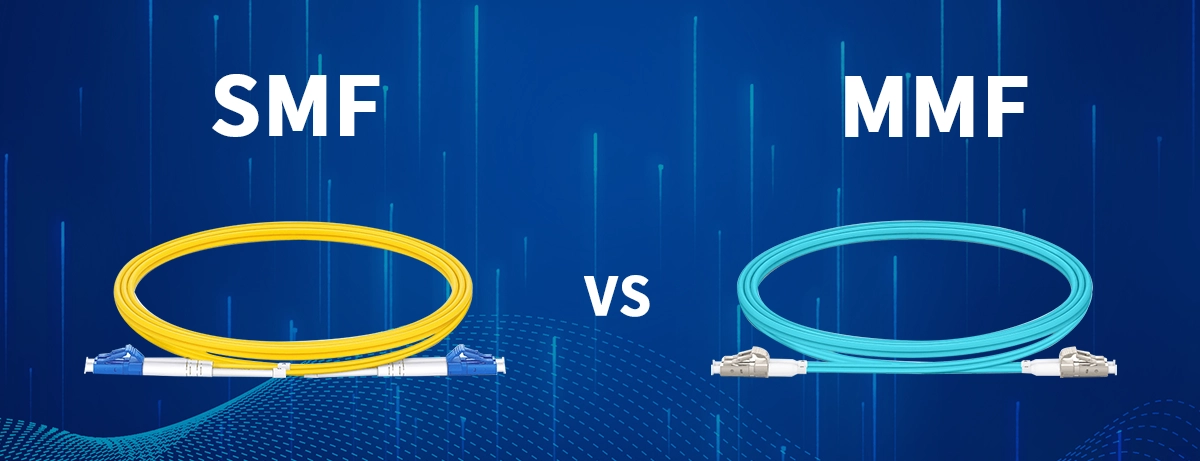

🔹 3) Fiber Type, Wavelength, and Link Budget

The optical design determines reach, performance, and signal quality. For industrial networks with varied installation paths, calculating the link budget is essential.

Core parameters

Multimode (MMF, 850 nm) for short-distance links.

Single-mode (SMF, 1310/1550 nm) for long-distance industrial backbones.

Wavelength: Match transceivers on both ends (e.g., 1310 nm ↔ 1310 nm).

Link budget:

Calculate based on transmitter power, receiver sensitivity, connector losses, splice losses, and fiber attenuation.

Add 3–6 dB safety margin for industrial environments where temperature and dust can impact performance.

🔹 4) Environmental Durability and Industrial Temperature Ratings

Industrial networks face extreme conditions—outdoor cabinets, factories, power substations, and transportation systems. Standard commercial SFPs often fail at temperature extremes.

Industrial-grade requirements

Operating temperature: typically –40°C to +85°C.

Rugged housing: enhanced mechanical strength for vibration and shock environments.

EMI/EMC robustness: essential for noisy industrial electrical environments.

Corrosion resistance: important for marine, chemical, and high-humidity applications.

Choosing modules explicitly rated for industrial use dramatically improves long-term reliability.

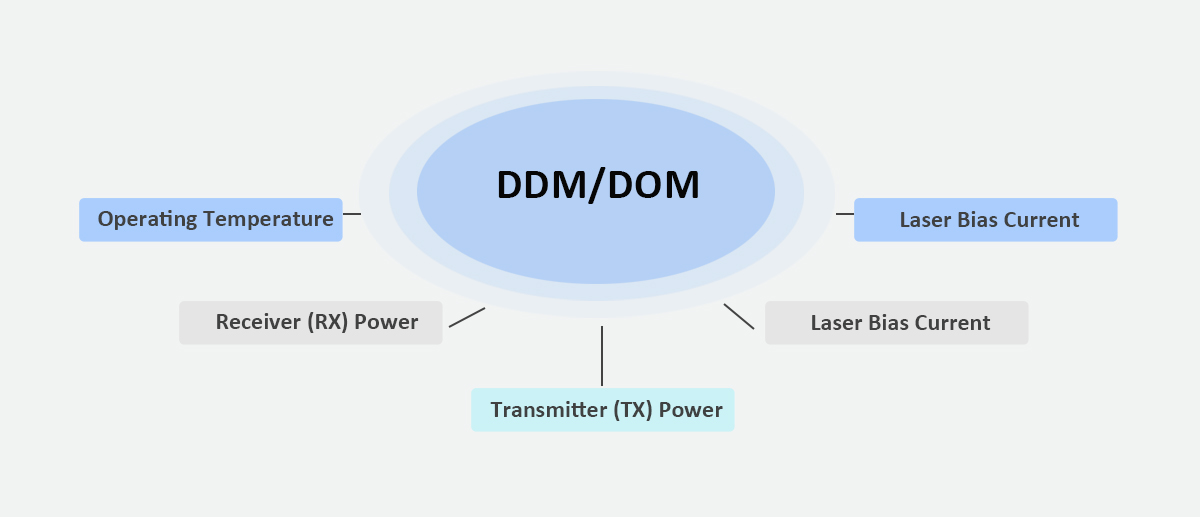

🔹 5) Digital Diagnostic Monitoring (DDM, SFF-8472)

DDM is essential for predictive maintenance, remote troubleshooting, and SLA-level monitoring.

Monitored parameters

Module temperature

Laser bias current

TX optical power

RX optical power

Supply voltage

Industrial operators benefit from early fault detection—such as fiber contamination, unexpected link loss, or thermal issues—enabling proactive maintenance before downtime occurs.

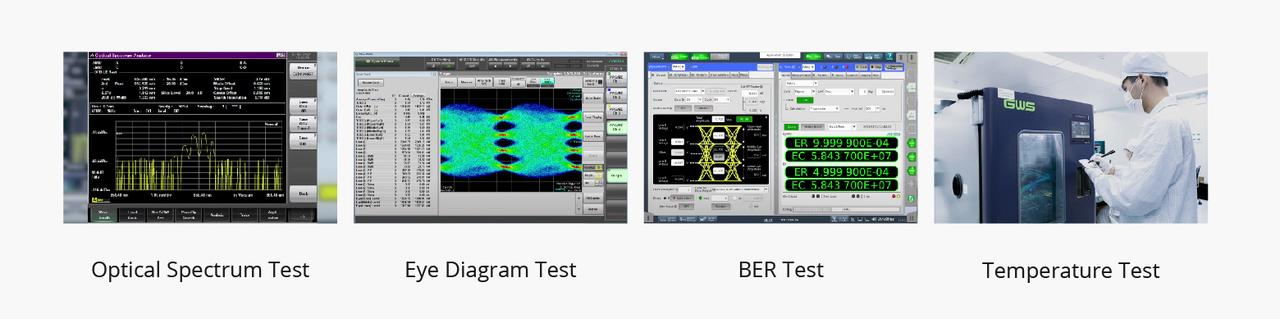

🔹 6) Reliability, Testing, Compliance, and MTBF

Reliability metrics and manufacturing processes matter as much as electrical specifications.

What to request

MTBF estimates based on recognized calculation models

Burn-in testing and sample test reports

Consistent part-number control and lifecycle management

Warranty and service availability for long-life installations

Industrial SFPs should undergo stricter screening than commercial models to maintain link availability in harsh deployments.

🔹 7) Power Consumption and Thermal Management

Higher-speed optics and copper SFPs generate more heat. In sealed industrial cabinets or fanless devices, heat buildup can shorten module lifespan.

Recommendations

Check maximum power consumption for SFP/SFP+/SFP28 modules.

Ensure the enclosure thermal design can handle continuous operation.

Use DDM temperature readings for trend analysis.

🔹 8) Security, Traceability and Supply Chain Integrity

Industrial automation systems require modules with transparent manufacturing processes and stable firmware.

Best practices

Choose vendors with controlled supply chains and traceable serial numbers.

Avoid unverified firmware-modified optics that may disable monitoring features.

For regulated industries, maintain documentation for each lot and firmware revision.

🔹 9) Total Cost of Ownership (TCO)

The lowest unit price rarely represents the true cost in industrial deployments.

TCO considerations

Failure rates and replacement labor

Troubleshooting and downtime costs

Vendor stability and product lifecycle

Need for spare-part inventory and compatibility across multi-vendor networks

Reliable industrial SFP modules reduce service calls and unplanned outages, lowering long-term operational expenses.

Example Selection Scenario

For an outdoor control cabinet connecting to a remote plant over 15km single-mode fiber, the recommended SFP module should include:

1310nm or 1550nm SMF transceiver depend on fiber attenuation

Sufficient link budget with margin for aging and environmental changes

Industrial temperature rating (–40°C to +85°C)

DDM support for remote monitoring

Verified compatibility with the installed industrial Ethernet switch

Industrial-grade SFP and SFP+ modules that meet these requirements are available in the LINK-PP catalog.

Practical Checklist for Purchasing Industrial SFP Modules

Host device compatibility confirmed

Correct data rate and form factor (SFP / SFP+ / SFP28)

Fiber type and wavelength match

Link budget calculated with the margin

Industrial temperature range verified

DDM (SFF-8472) required for critical networks

Vendor test reports and MTBF data reviewed

Lifecycle and sustainability

Conclusion

Selecting industrial SFP modules involves more than matching part numbers. Engineers must evaluate compatibility, optical parameters, environmental durability, diagnostics, and vendor reliability to ensure dependable long-term network performance. By applying these criteria, organizations can build fiber networks that remain stable in harsh environments and deliver consistent uptime.

For certified industrial-grade SFP and SFP+ transceivers designed for rugged applications, explore LINK-PP’s store online.