Introduction

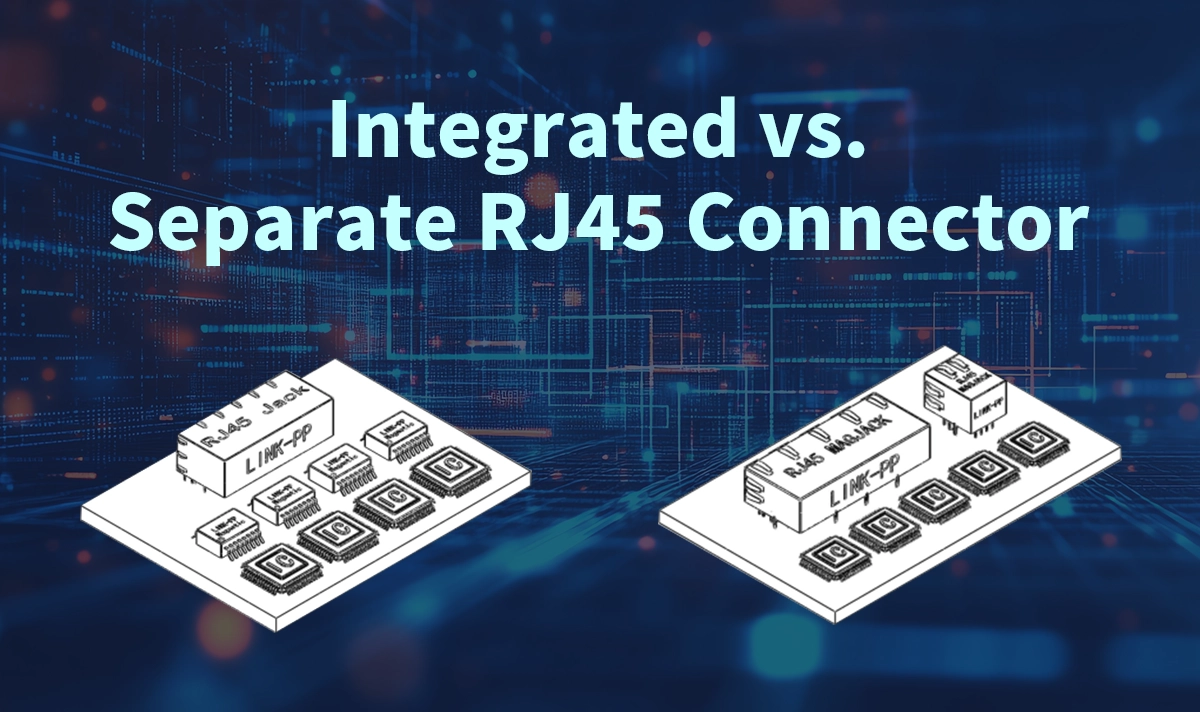

In Ethernet-based networking hardware, the choice between integrated and separate (or modular) RJ45 connector designs plays a critical role in determining signal quality, EMI performance, PCB complexity, cost, and overall system reliability. As Ethernet technology continues to evolve and expand into industrial, automotive, and compact IoT applications, understanding the trade-offs between these two design philosophies is essential for hardware engineers and product developers.

This article provides a technical comparison of Integrated RJ45 Connectors (also known as MagJack) and Separate RJ45 Designs, highlighting their structure, benefits, limitations, and ideal use cases.

1. What Is an Integrated RJ45 Design?

An Integrated RJ45 connector combines the standard 8P8C Ethernet interface with built-in magnetic components—including isolation transformers, common-mode chokes, and sometimes LEDs—into a single compact unit. These modules are often referred to as MagJack and are widely used in commercial networking equipment, industrial controllers, and compact embedded systems.

Key Characteristics:

Built-in magnetics for signal isolation and EMI suppression.

Simplified PCB layout, reducing routing complexity.

Smaller footprint on the PCB.

Standardized electrical performance, tested as a complete unit.

Advantages:

Space-efficient: Ideal for high-density or size-constrained designs.

Reduced design complexity: Fewer external components ease PCB design.

Faster time-to-market: Pre-integrated modules accelerate development cycles.

Improved reliability: Magnetics are factory-matched and tested for optimal performance.

Disadvantages:

Relatively Limited customization: Magnetic characteristics (e.g., turns ratio, insertion loss) are fixed by the manufacturer.

Higher unit cost for low-volume production: Integrated modules may be more expensive in small batches.

Maintenance complexity: Failure in any subcomponent requires replacing the entire module.

Ideal For:

Compact or space-sensitive designs (e.g., industrial switches, embedded systems).

Projects requiring quick development with minimal signal tuning.

Medium- to low-volume applications where simplicity and speed are prioritized.

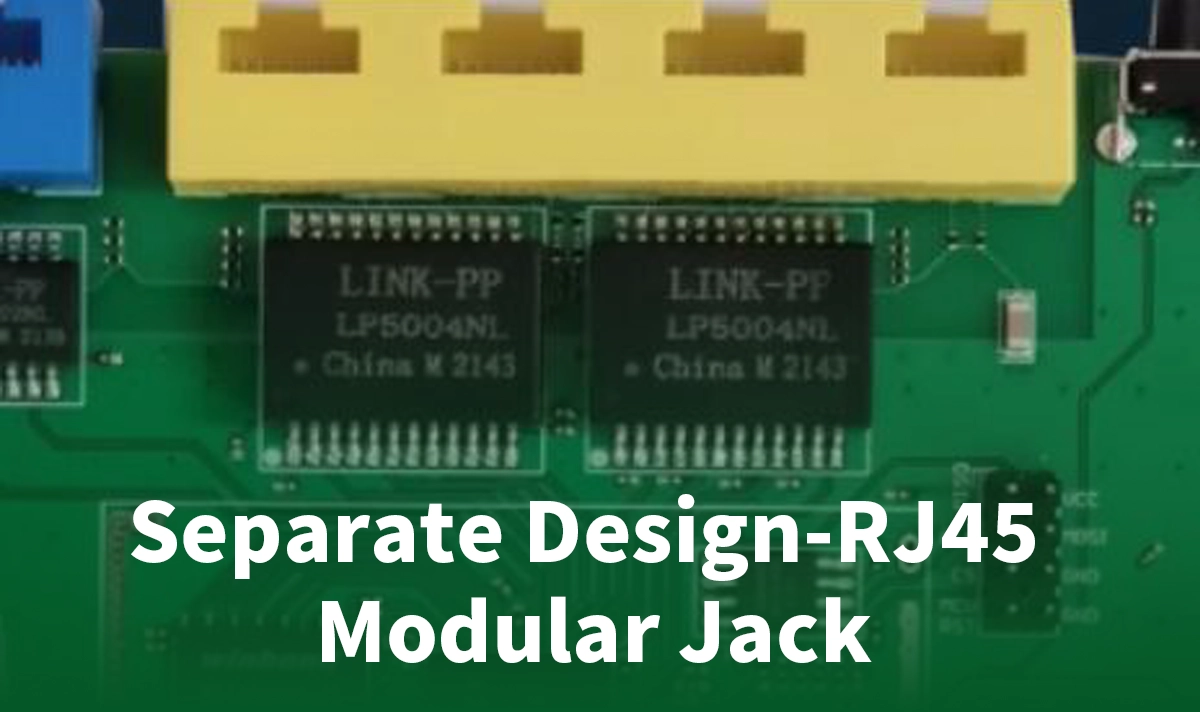

2. What Is a Separate RJ45 Design?

A Separate RJ45 design uses an unmagnetized modular jack for the physical Ethernet port, while the magnetic components—such as signal / Ethernet Transformers and common-mode chokes—are placed as discrete components on the PCB. This approach allows engineers to select each component individually based on system requirements.

Key Characteristics:

Disaggregated design: Connector and magnetics are separate units.

Flexible magnetic tuning: Designers can optimize EMI, signal integrity, and return loss.

Typically used in high-performance or highly customized systems.

Advantages:

Greater design flexibility: Magnetic characteristics can be selected or adjusted per application.

Cost-effective at high volumes: Component-level sourcing can reduce BOM cost in mass production.

Easy maintenance: Faulty components can be replaced individually.

Enhanced EMI/EMC optimization: Particularly useful for multi-port systems or systems under regulatory constraints.

Disadvantages:

Larger PCB area required: Discrete magnetics and connectors consume more board space.

Increased layout complexity: Requires careful routing, impedance control, and component placement.

Longer development time: Additional validation and tuning may be necessary.

Ideal For:

Custom-designed hardware platforms (e.g., high-end routers, telecom base stations).

Systems requiring specific EMI/EMC performance.

Mass-production projects where BOM flexibility can reduce per-unit costs.

3. Head-to-Head Comparison

Feature | Integrated Design | Separate Design |

|---|---|---|

Magnetic Components | Built-in | External discrete components |

PCB Complexity | Low | High |

Board Space Required | Minimal | Larger footprint |

Signal Tuning Flexibility | Limited | High |

EMI/EMC Optimization | Pre-engineered | Fully customizable |

Repairability | Replace full module | Replace individual components |

Development Time | Faster | Slower |

Cost (Low Volume) | Higher | Lower |

Cost (High Volume) | Competitive or lower | Potential cost savings |

Applications | Industrial Ethernet, IoT, switches | Carrier-grade systems, telecom, servers |

4. Choosing the Right Solution

The decision between integrated and separate RJ45 connector designs should be based on the specific goals and constraints of your project. Consider the following:

Go with Integrated Design if:

You need to save board space.

You want to simplify your BOM and PCB layout.

You have tight development timelines.

Choose Modular Design if:

You require signal tuning or custom EMI performance.

You're working on a high-performance or multi-port platform.

Your design team has experience with magnetics layout and tuning.

You want more sourcing control.

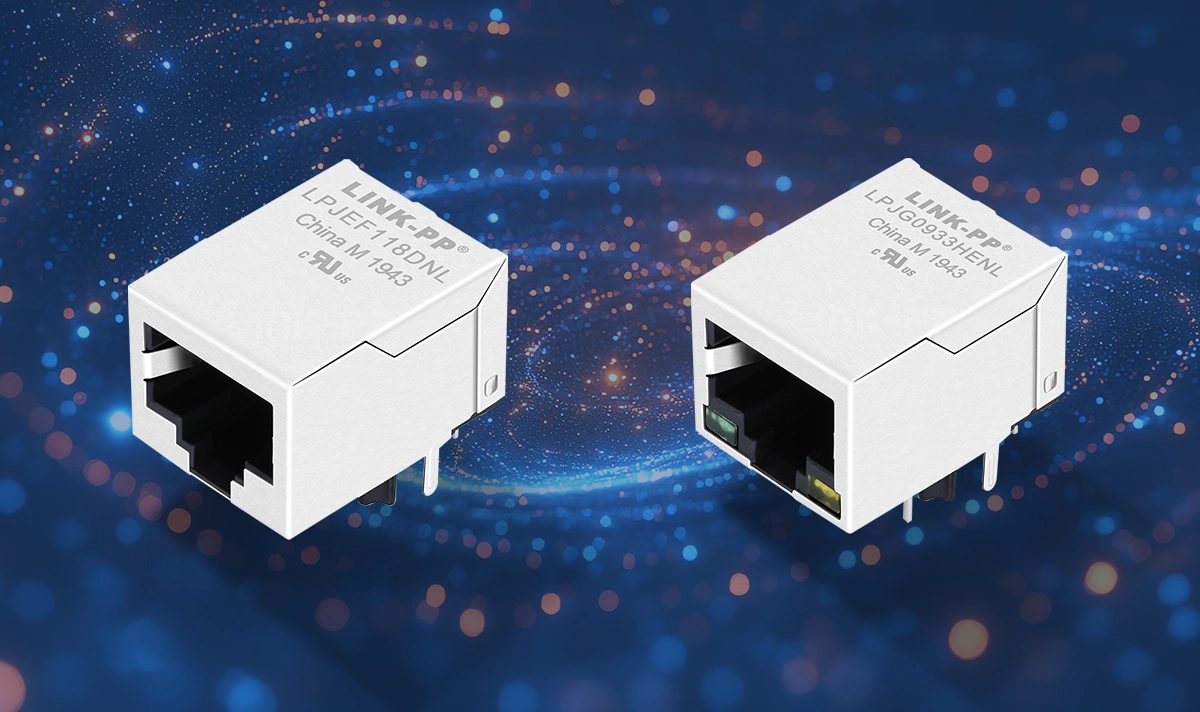

5. LINK-PP Solutions

LINK-PP offers a comprehensive portfolio of both integrated RJ45 connectors and discrete magnetic transformers, supporting various Ethernet standards.

Example Products:

LPJG0926HENL – 1G MagJack with LEDs and PoE+ support

LPJU3102ABNL – RJ45 Combo USB connector for compact devices

LPJG0933HENL – 1000 Base-T RJ45 Magnetic Jack for BeagleBone AI-64

LPJE180NNL – 1X1 Port RJ45 Connector without Integrated Magnetics

LPJE680DNL – 8P8C Vertical RJ45 Modular Jack

Conclusion

Choosing between integrated and separate RJ45 designs depends on your space, cost, and performance needs. Integrated connectors offer simplicity and compactness, while separate designs provide more flexibility and customization.

LINK-PP provides both solutions with high quality, competitive pricing, and global support. Whether you need a compact MagJack or a discrete design for EMI-sensitive applications, LINK-PP helps you build reliable Ethernet connections faster.

🔗 See Also

Application of RJ45 Connectors in Network and Industrial Systems

Explore how RJ45 connectors are applied across various industries, including networking, automation, and smart devices.Magnetic RJ45 Jack: Integrated Connector Modules Explained

Learn more about how integrated magnetic RJ45 modules simplify PCB design and improve signal integrity in Ethernet systems.LINK-PP LPJG0926HENL: RJ45 Connector with Integrated Magnetics (PoE+)

A product spotlight featuring LPJG0926HENL — a compact, high-performance RJ45 connector with built-in magnetics and PoE+ support.