① Overview

In modern automation systems, an Industrial PC (IPC) often serves as a data aggregation or edge-processing node, collecting large volumes of information from distributed I/O modules. This data must then be transmitted to a Programmable Logic Controller (PLC) for real-time control. Ensuring stable, noise-resilient Ethernet communication between these devices is critical—especially in electrically harsh industrial environments.

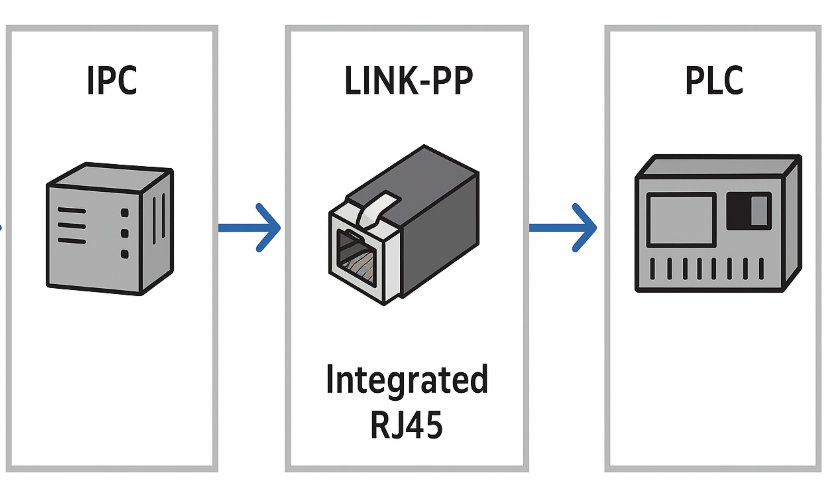

This case study explores how an IPC connects to a PLC through industrial Ethernet while using a LINK-PP integrated RJ45 connectors to guarantee galvanic isolation, EMI suppression, and long-term reliability.

② System Architecture

IPC as the Edge Processor

The IPC reads multiple I/O modules—analog sensors, digital inputs, actuators, and field devices—and processes the aggregated data for logic execution, monitoring, or predictive analytics.

Ethernet Link to the PLC

The processed data is transferred from the IPC to the PLC through a standard industrial Ethernet interface, supporting protocols such as Modbus TCP, EtherNet/IP, or PROFINET.

LINK-PP RJ45 Integrated Magnetics

Between the IPC’s Ethernet PHY and the external network sits the LINK-PP integrated RJ45 connector. This module includes:

Isolation transformer

Common-mode and differential chokes

Shielded housing

Optional link/activity LEDs

These components collectively provide isolation, noise filtering, and robust signal integrity for stable IPC-PLC communication.

③ Why LINK-PP RJ45 Magjack Is Essential in This Scenario

▷ Galvanic Isolation for Device Protection

Industrial sites often experience ground loops and transient voltages. The integrated magnetics ensure up to 1.5 kVrms isolation between the cable side and the IPC’s Ethernet PHY, protecting both IPC and PLC hardware.

▷ Superior EMI Suppression

With motors, relays, and inverters nearby, Ethernet lines face significant electromagnetic interference. LINK-PP’s magnetics filter common-mode noise and maintains signal stability under high EMI exposure.

▷ Reliable Performance Across Harsh Conditions

The shielded RJ45 housing and –40 °C to +85 °C operating range ensure consistent performance in control cabinets, machine enclosures, and extended-temperature environments.

▷ Space-Saving PCB Integration

By combining the RJ45 interface and magnetic components into one compact module, IPC designers reduce board complexity and improve mechanical reliability—especially in fanless or compact IPCs.

④ Data Path: From I/O Modules to PLC

I/O Data Acquisition

The IPC continuously polls external sensors and actuators through a fieldbus or distributed I/O systems.Edge Logic and Preprocessing

Data is filtered, timestamped, or analyzed to reduce PLC workload.Ethernet Transmission

The IPC sends the resulting data frame through its LAN interface, routed through the LINK-PP RJ45 with integrated magnetics.PLC Receives Processed Data

The PLC executes deterministic control tasks based on the preprocessed and validated data.Stable Physical Layer Ensured by LINK-PP

The magnetics maintain differential signal quality, reduce packet errors, and minimize retransmissions—even in high-noise zones.

⑤ Real-World Application Example

A machine builder integrates an IPC as a supervisory controller to manage a multi-axis motion system:

The IPC collects feedback from I/O modules connected to motors, limit switches, and temperature sensors.

It preprocesses the data and sends command updates to the PLC.

A LINK-PP RJ45 integrated connector ensures the Ethernet line remains stable despite nearby high-voltage drives and switching equipment.

The PLC executes deterministic cycle-time control with minimal communication latency or jitter.

The result is a robust closed-loop automation system with strong communication reliability.

⑥ Engineering Benefits

Fewer communication errors in EMI-dense environments

Better long-term reliability due to integrated magnetics

Simplified mechanical and PCB layout

Improved equipment protection via isolation

Stable industrial Ethernet performance across temperature extremes

⑦ Conclusion

In IPC-to-PLC architectures, physical-layer reliability is vital for maintaining stable industrial Ethernet links. By integrating a LINK-PP RJ45 connector with built-in magnetics, engineers gain essential EMI suppression, isolation, and signal integrity—ensuring dependable data exchange between I/O modules, IPCs, and PLCs.

LINK-PP’s integrated RJ45 solutions enable high-performance industrial communication in compact, EMI-challenging environments, making them a trusted choice for IPC and automation equipment designers worldwide.