✅ Introduction

I/O modules (Input/Output modules) serve as the foundational interface between a control system and the outside world. Whether in industrial automation, embedded platforms, or modern network equipment, I/O modules manage how physical devices exchange signals, data, and control instructions with a central processor.

As networks transition to higher speeds and industrial systems adopt smarter, more distributed architectures, the performance and reliability of I/O modules directly influence system stability, latency, and data integrity. This article provides a complete technical overview suitable for engineers, integrators, and system designers.

✅ Definition: What Are I/O Modules?

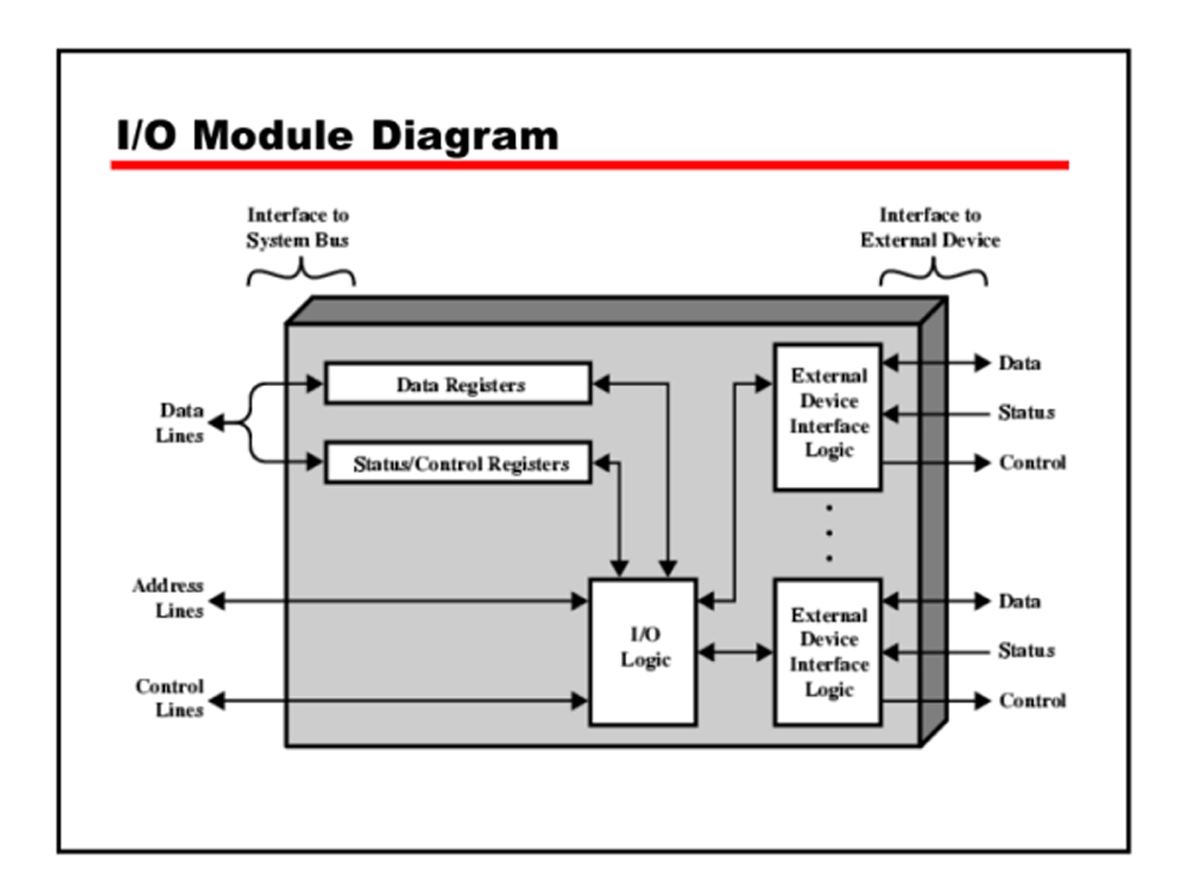

An I/O module is a hardware component that enables a controller—such as a PLC, industrial PC, embedded SoC, or network processor—to communicate with external equipment. It handles:

Input (I): Receiving data or electrical signals from sensors or external devices

Output (O): Sending commands or electrical signals to actuators or network interfaces

Signal Conversion: Mapping between electrical/optical/logic levels

Protocol Handling: Supporting specific communication standards

In essence, I/O modules form the physical and logical bridge between a system’s internal computing resources and the operating environment.

✅ Why I/O Modules Are Critical

1. Signal Conditioning & Conversion

I/O modules often convert between:

Analog ↔ Digital

Low-voltage logic ↔ Industrial-level currents

Electrical ↔ Optical signals (e.g., in SFP/SFP+ modules)

This ensures accurate data acquisition and safe control output.

2. Electrical Isolation & Protection

Isolation barriers (magnetic, optical, or capacitive) protect the system from:

Isolation is crucial in industrial sites and high-speed network hardware.

3. Interface Expansion

I/O modules allow systems to scale by adding:

Ethernet ports

Serial channels

Sensor inputs

High-speed optical links

This modularity keeps systems flexible and future-proof.

4. Real-Time Operation Support

In automation and networking, latency-sensitive applications rely heavily on I/O responsiveness—particularly for:

Motion control

Factory automation

Data center switching

Telecom transmission

✅ Types of I/O Modules

▷ Digital I/O Modules

Used for switches, relays, discrete sensors.

Typical signals: 0/24 VDC, TTL, or dry contacts.

▷ Analog I/O Modules

Handle variable electrical signals.

Examples:

4–20 mA loops

0–10 V

Temperature probes (RTD/thermocouple)

▷ Communication I/O Modules

Expand interface protocols such as:

RS-232/485

CAN

Modbus

EtherCAT

PROFINET

▷ Network Interface I/O Modules

Used in switches, routers, servers, and telecom hardware. They include:

This category is key to modern networking infrastructure.

✅ I/O Modules in Networking Devices

In network equipment, I/O modules perform both physical-layer and data-link-layer functions. A typical network I/O subsystem includes:

Ethernet PHYs (signal conditioning, auto-negotiation, PCS/PMA)

SerDes lanes for high-speed serial transmission

Magnetics/RJ45 Magjack modules for copper interfaces

Optical transceiver modules (SFP/SFP+/QSFP+) for fiber connectivity

Why They Matter:

Stable clock recovery ensures low jitter

Accurate optical/electrical conversion supports long-distance links

High-speed interfaces reduce packet loss and latency

Hot-swapping enables flexible upgrades in data centers

✅ I/O Modules in Industrial Automation

Industrial systems rely heavily on reliable I/O to interact with physical processes. I/O modules connect PLCs or controllers to:

Sensors (pressure, temperature, vibration)

Actuators (motors, valves, relays)

Industrial networks (EtherNet/IP, Modbus TCP, PROFINET)

Key Requirements:

High isolation voltage

Deterministic timing

Support for hazardous-area standards

These characteristics ensure plant uptime and safety.

✅ Example Application: 10G SFP+ Modules as High-Speed Network I/O

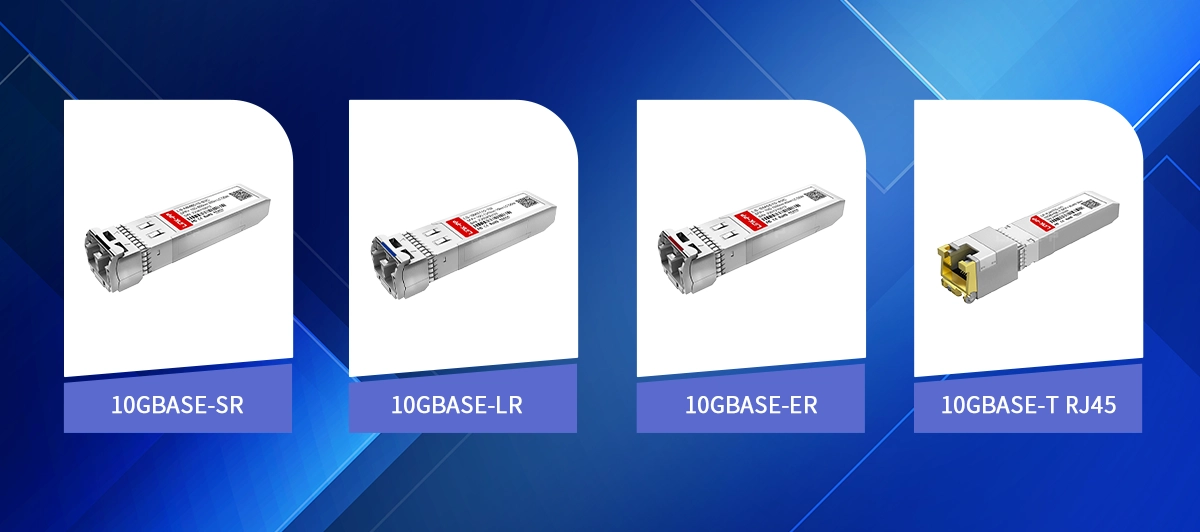

In modern enterprise and telecom networks, 10G SFP+ modules are among the most widely used network I/O components. They function as removable, hot-swappable interfaces that convert high-speed electrical signals from the system’s SerDes into optical signals suitable for fiber transmission.

Common Applications

Ethernet switches

Data center servers

Storage systems

Wireless backhaul

Industrial IP networks

Why LINK-PP 10G SFP+ I/O Modules Fit These Scenarios

LINK-PP’s 10G SFP+ transceivers offer:

Reliable signal integrity with low jitter and low BER

Compatibility with mainstream switch ASICs

Industrial-grade temperature options for harsh environments

Flexible distances (from 300 m SR to 10 km/40 km LR/ER)

Stable optical performance + robust EMI design

These modules serve as a key part of a network’s I/O subsystem, enabling fast, stable, and long-distance fiber connectivity.

✅ Benefits of Using High-Quality I/O Modules

Improved system reliability

Higher data throughput

Reduced noise interference

Extended communication distance

Increased design flexibility

Lower maintenance and replacement costs

Whether in factory automation or cloud infrastructure, well-designed I/O modules help ensure consistent system performance.

✅ Conclusion

I/O modules are fundamental building blocks for any system that needs to interact with the physical world or external networks. From digital and analog modules in industrial equipment to high-speed SFP+/RJ45 network interfaces in modern Ethernet hardware, I/O modules determine how accurately, safely, and efficiently data travels between systems.

As networks scale to multi-gigabit speeds and industrial systems adopt smarter architectures, selecting reliable I/O solutions—such as properly engineered 10G SFP+ modules—becomes essential for long-term stability and performance.