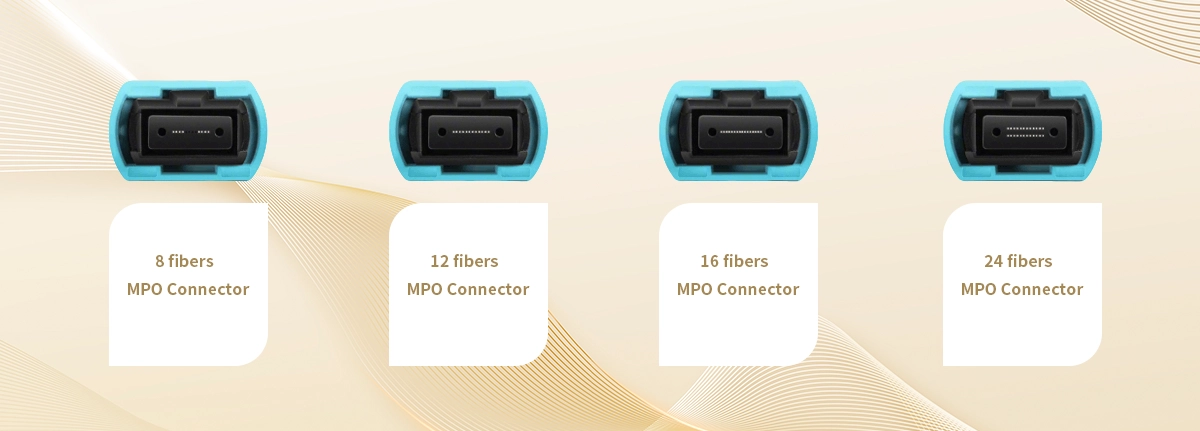

When you look at 8, 12, 16, and 24 fiber MPO connectors, you can see they have different numbers of fibers and designs. Each one is good for different network jobs. The number of fibers changes how you set up your network and how much you can grow it later. Picking the right MPO/MTP connectors helps your data center work better and get ready for new upgrades. Many experts also use MTP connectors because they are exact and dependable. You will see MTP and MPO connectors often used together in fast networks. Choosing the right kind helps your network stay fast and work well as technology changes.

📝 Understanding the MPO Connector: A Density Powerhouse

The MTP®/MPO (Multi-fiber Push-On/Pull-off) connector is the backbone of modern high-speed data centers and telecom networks. Its core advantage lies in terminating multiple optical fibers (8, 12, 16, or 24) within a single, compact ferrule. This revolutionary design enables rapid deployment of high-density fiber optic cabling, essential for supporting bandwidth-hungry applications like cloud computing, AI workloads, 5G backhaul, and hyperscale data centers.

📝 Why Core Count Matters: It’s All About Application & Efficiency

The number of fibers within an MPO connector isn't arbitrary. Each core count is engineered to align with specific parallel optic transceiver technologies (like QSFP+, QSFP28, QSFP-DD, OSFP) and transmission standards (40G, 100G, 200G, 400G, 800G). Choosing the correct count ensures:

Optimal Bandwidth Utilization: Matching the connector to the transceiver lane count avoids wasted fibers or bottlenecks.

Maximized Rack Density: Higher fiber counts (16f, 24f) enable more connections per rack unit.

Simplified Cabling & Polarity: Structured cabling designs rely on specific MPO counts for predictable, error-free deployments.

Future-Proofing: Selecting a count aligned with future migration paths protects your investment.

Cost Efficiency: Using the right count avoids over-provisioning or under-utilizing expensive fiber infrastructure.

📝 Deep Dive: Core Count Differences & Applications

Let's break down the specifics of each common MPO core count:

The Legacy Workhorse: 8-Fiber MPO Connectors

Structure: Houses 8 fibers in a single row (1x8).

Primary Historical Use: Primarily used for early 40G Ethernet implementations using the 40GBASE-SR4 standard. The 4 transmit and 4 receive lanes of the SR4 transceiver mapped directly to 4 fibers each way within the 8-fiber MPO.

Modern Relevance: Less common for new high-speed data center deployments targeting 100G+.

Limitations: Lower fiber density compared to 12f, 16f, and 24f options. Not directly compatible with common 100G transceivers without breakout.

The Industry Standard: 12-Fiber MPO Connectors

Structure: Houses 12 fibers, typically arranged in a single row (1x12). The dominant standard for over a decade.

Dominant Application: The workhorse for 100G Ethernet (100GBASE-SR4), where 4 fibers transmit and 4 fibers receive (utilizing 8 fibers), leaving 4 fibers unused or for bidirectional applications. Also foundational for 40G BiDi (40GBASE-SR-BiDi) using WDM over just 2 fibers (often within a 12f MPO).

Migration Path: Forms the basis for migrating to higher speeds via breakout cabling (e.g., one 12f trunk splitting into three 4-fiber LC duplex connections for 3x 10G links).

Density & Compatibility: Offers excellent balance. Vast ecosystem of mpo patch panels, mpo trunk cables, cassettes, and fiber optic transceivers designed around the 12f standard.

The High-Density Enabler: 16-Fiber MPO Connectors

Structure: Houses 16 fibers, arranged in single row (1x16) within the same standard MPO footprint.

Emerging Application: Designed to efficiently support next-generation 200G and 400G Ethernet using breakout cabling schemes, particularly with OSFP and QSFP-DD transceivers. For example:

A single 400G-SR8 transceiver uses 8 fibers Tx and 8 fibers Rx. A 16-fiber MPO trunk cable provides a direct, 1:1 connection path without unused fibers.

A 400G-SR4.2 transceiver can use a single 16-fiber MPO trunk to break out into two independent 200G-SR4 links.

Density Advantage: Doubles the fiber count within the same physical connector space as a 12f single-row MPO, significantly boosting rack density.

Breakout Efficiency: Provides a cleaner, more efficient path for splitting high-speed links into multiple lower-speed links compared to using multiple 12f connectors.

Compatibility: Requires specific 16-fiber cassettes and patch panels. Polarity management follows TIA-568.0-D/E standards (Types C & D).

The Ultimate Density Solution: 24-Fiber MPO Connectors

Structure: Houses 24 fibers, densely packed in two rows (2x12) within the standard MPO footprint.

Cutting-Edge Application: Primarily targeting 800G Ethernet deployments, enabling maximum port density and minimizing cable bulk. Key uses:

800G-SR8: Uses 8 fibers Tx and 8 fibers Rx (16 fibers). A 24f trunk can support one 800G link and have 8 fibers spare for another link or future use.

Breakout Scenarios: Efficiently breaks out to multiple 100G, 200G, or 400G links (e.g., one 24f trunk to six 100G-SR4 links).

Density Champion: Represents the highest commercially available fiber density per MPO connector, crucial for hyperscale data centers and AI/ML clusters where space and airflow are paramount.

Efficiency: Minimizes the number of physical connectors and cables needed for ultra-high bandwidth, simplifying pathways and improving airflow.

Compatibility: Requires 24-fiber specific infrastructure (panels, cassettes). Polarity follows TIA standards (Types C & D for duplex applications).

MPO Core Count Comparison at a Glance

This table summarizes the key differences and applications:

Feature | 8-Fiber MPO | 12-Fiber MPO (Standard) | 16-Fiber MPO (1x16) | 24-Fiber MPO (2x12) |

|---|---|---|---|---|

Fiber Arrangement | 1x8 (Single Row) | 1x12 (Single Row) | 1x16 (Single Row) | 2x12 (Dual Row) |

Dominant Applications | Legacy 40G (SR4) | 100G (SR4), 40G BiDi, Migration Breakout | 200G/400G Breakout, 400G SR8 | 400G/800G, Hyperscale, AI/ML |

Key Speed Support | 40G | 40G, 100G | 200G, 400G | 400G, 800G |

Density Rating | ★★☆☆☆ | ★★★☆☆ | ★★★★☆ | ★★★★★ |

Breakout Efficiency | Low | Medium (e.g., 12f -> 3x10G) | High (e.g., 16f -> 2x200G or 1x400G) | Very High (e.g., 24f -> 3x400G or 1x800G + spare) |

Infrastructure Commonality | Low | Very High | Growing | Growing (Hyperscale Focus) |

Primary Use Case Today | Legacy Upgrades | Mainstream 100G, Migration Paths | Next-Gen 200G/400G Deployments | Ultra-High Density 400G/800G, AI/ML |

📝 Choosing the Right MPO Core Count: Key Considerations

Selecting the optimal MPO fiber count requires a strategic approach:

Current & Target Speeds (40G/100G/200G/400G/800G): What are you deploying now? What's your 1-3 year and 5+ year roadmap? Don't just solve for today.

Transceiver Technology (QSFP+, QSFP28, QSFP-DD, OSFP): Match the MPO count to the native lane configuration of your chosen transceivers (e.g., SR4 uses 4 lanes, SR8 uses 8 lanes). Consult transceiver datasheets.

Cabling Topology (Direct Attach vs. Breakout): Will you use direct MPO-MPO connections between transceivers? Or will you break out high-speed ports into multiple lower-speed ports using MPO cassettes or MPO-LC harnesses? Breakout heavily influences optimal core count.

Rack Density Requirements: How critical is maximizing ports per RU? Hyperscale data centers and AI/ML infrastructure heavily favor 16f and especially 24f for maximum density.

Existing Infrastructure: Migrating from a 12f base? Leverage breakout strategies. Greenfield deployment? Future-proof with higher counts.

Cost: While higher-density connectors offer better long-term value and density, upfront costs for cables, cassettes, and compatible transceivers can differ. Factor in total cost of deployment and future upgrade costs. Higher density often wins on TCO.

Standard Compliance (TIA-568, IEC 61754-7): Ensure chosen components (connectors, cables, cassettes) adhere to relevant standards for performance and interoperability, especially for polarity management.

📝 Future Trends: Where is MPO Density Heading?

The relentless demand for bandwidth drives continuous innovation:

Beyond 24 Fibers? While technically possible, mechanical constraints and alignment challenges make significantly higher counts within the standard MPO footprint difficult. Focus remains on optimizing 16f and 24f.

Single-Mode Dominance for Long Haul/800G+: While multimode (OM4/OM5) powers many SR links within data centers, single-mode fiber and connectors like LC duplex and reduced-footprint SN/MDC are essential for 800G-FR4/DR8/LR8 and beyond over distance.

Co-Packaged Optics & On-Board Optics: These emerging technologies aim to move optics closer to or directly onto the switch ASIC, potentially changing interconnect requirements but unlikely to eliminate the need for high-density fiber cabling like MPO for rack-to-rack connections anytime soon.

Enhanced MPO Designs: Expect continued refinements in MPO connector ferrule materials, polishing techniques (APC options for SM), and latching mechanisms for even higher reliability in dense environments.

📝 Conclusion & Key Takeaways

Choosing the correct MPO connector core count is fundamental to building efficient, scalable, and high-performance optical networks. Understanding the distinct roles of 8, 12, 16, and 24-fiber variants empowers you to make informed decisions:

8 fibers: Legacy 40G, diminishing role.

12 fibers: The established standard for 40G/100G, versatile for migrations. Still highly relevant.

16 fibers: The strategic choice for efficient 200G/400G SR8 deployments and breakout, offering excellent density.

24 fibers: The high-density fiber champion for 400G/800G and hyperscale data centers, maximizing port density and minimizing cable bulk.

Align your choice with your target speeds, transceiver technologies, density needs, and future roadmap. Prioritize standards compliance and meticulous polarity management.

📝 FAQ

What is the main difference between 8, 12, 16, and 24 fiber MPO connectors?

You will see the main difference in the number of fibers each connector holds. This changes how much data you can move and which LINK-PP optical modules you can use, like LQ-M8540-SR4C for 12 fiber.

Can I mix different MPO connector types in my network?

You should not mix different MPO connector types directly. The fiber counts and pin layouts do not match. If you need to connect different types, you must use special adapters. Always check your LINK-PP optical module specs before connecting.

How do I choose the right MPO connector for my data center?

You should look at your network speed, future growth, and space needs. For high-density racks, pick 24 fiber MPO connectors. For flexible setups, use 12 fiber MPO. LINK-PP optical transceiver modules work with many connector types.

Do I need to worry about polarity with MPO connectors?

Yes, you must check polarity to make sure signals travel the right way. LINK-PP MPO and MTP connectors offer clear markings. Always match the polarity type to your optical modules.

Are MPO connectors future-proof for higher speeds?

You can future-proof your network by choosing higher fiber count MPO connectors, like 16 or 24 fiber. These support upgrades to 400G and beyond.