In the field of LAN transformers, especially for Ethernet applications, terms like “Package Type” and “Mounting Type” are frequently mentioned in product datasheets. While they may appear similar, they refer to very different design characteristics. Understanding the distinction is critical for PCB layout, automated assembly, thermal management, and long-term reliability. This article breaks down the difference and explains their significance in transformer selection—using LINK-PP’s LP82487PNL 24-pin PoE+ LAN Transformer as an example.

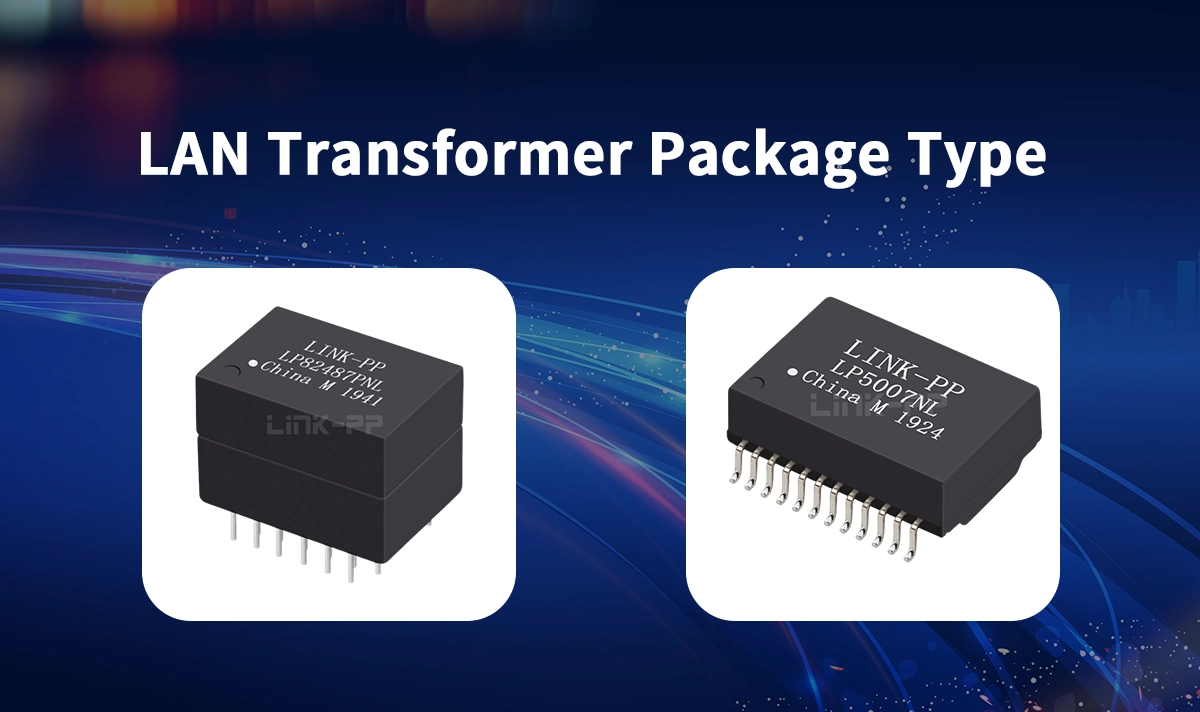

What is Package Type?

Package Type refers to the physical form factor and external geometry of the LAN transformer. It defines how the component is shaped and what it looks like from the outside. Key considerations include:

Body dimensions (length, width, height)

Number of pins or terminals

Pin layout and spacing (pitch)

Encapsulation type (e.g., plastic mold, epoxy filled)

📌 Example: The LP82487PNL from LINK-PP uses a 24-pin DIP (Dual In-line Package) with a rectangular footprint and evenly spaced dual-row pins.

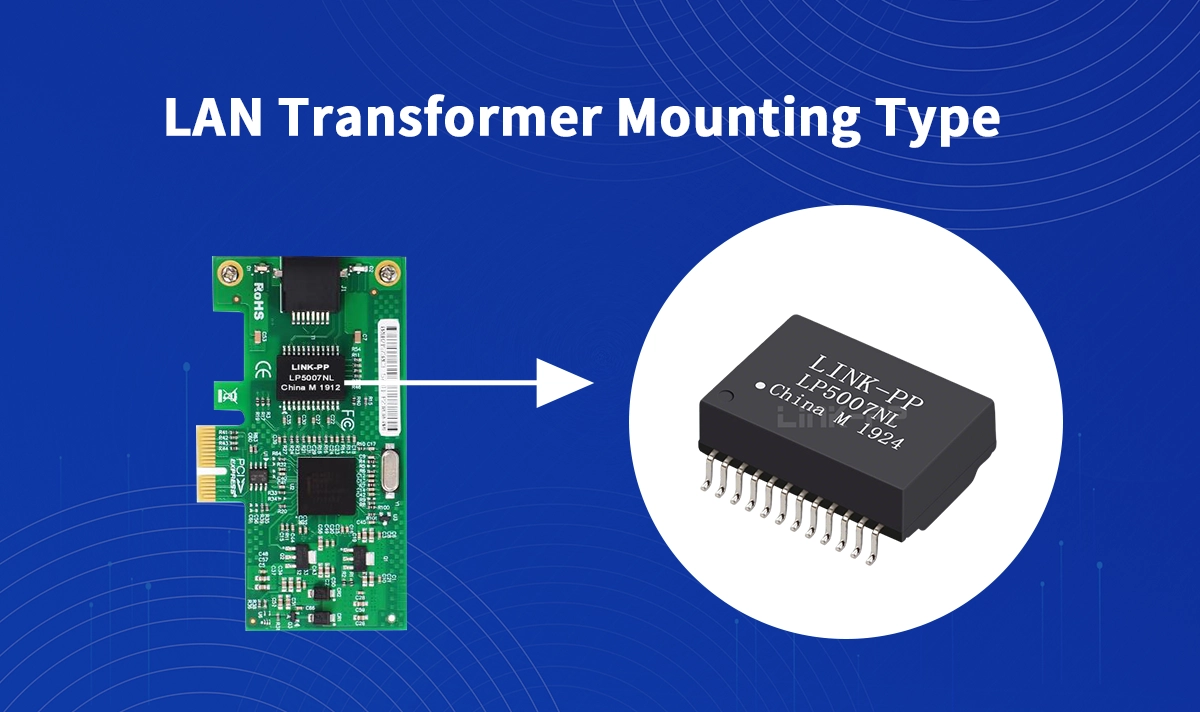

What is Mounting Type?

Mounting Type describes how the transformer is attached to the printed circuit board (PCB) during assembly. It determines the method of soldering and mechanical connection:

Through-Hole Technology (THT):

Pins go through pre-drilled holes in the PCB and are soldered on the opposite side—commonly used with DIP packages.Offers strong mechanical bonds

Preferred in high-reliability or high-power applications

Compatible with wave soldering processes

Surface-Mount Technology (SMT):

Components are mounted directly onto the surface of the PCB with flat leads or terminals.Ideal for automated assembly and compact designs

Compatible with reflow soldering

Often used with SMD-style LAN transformers

Package Type vs. Mounting Type: A Summary of Differences

Aspect | Package Type | Mounting Type |

|---|---|---|

Definition | Shape and form of the component | How it is attached to the PCB |

Examples | DIP, SMD, QFP, SIP | THT (Through-Hole), SMT (Surface Mount) |

Affects | PCB footprint, pin configuration | Assembly method, mechanical strength |

Typical Usage | Shown in datasheet “package” | Indicated in product “mounting style” |

Why the Difference Matters in Design

Understanding both terms is essential during component selection and PCB layout:

Manufacturing Compatibility:

SMT is more suited for automated pick-and-place lines; THT may require manual insertion or wave soldering.Thermal Management:

THT can dissipate more heat into the PCB due to deeper anchor points.Signal Integrity & EMI:

Packaging can affect shielding, pin isolation, and magnetic structure design.Mechanical Durability:

THT components like DIP LAN transformers are more robust in high-vibration environments.

Real-World Example: LINK-PP LP82487PNL

The LP82487PNL is a 10/100/1000BASE-T LAN transformer with PoE+ support. It features:

DIP Package: 24-pin, dual-row, standard layout

Through-Hole Mounting: Ideal for strong mechanical connections and wave solder assembly

Applications: Network switches, routers, PoE injectors

📎 View Product Details

📎 Download Datasheet

Conclusion

The difference between package type and mounting type is subtle but crucial when designing Ethernet interfaces. Packaging defines the component’s form, while mounting defines how it connects to your PCB. Selecting the right combination—such as DIP + THT for rugged performance—can significantly impact reliability, manufacturability, and cost. LINK-PP offers a wide range of LAN transformers with both DIP and SMT options to match your application requirements.