Through Hole Technology (THT) involves assembling electronic components by inserting their leads into pre-drilled holes on a printed circuit board (PCB) and securing them with solder. This method ensures robust connections, making it ideal for applications requiring high reliability. In 2023, over 1.5 billion through-hole passive components were produced in the U.S., driven by demand from the automotive and industrial sectors. The global market for these components is projected to grow significantly, reaching USD 69.76 billion by 2032. THT through hole technology continues to play a vital role in modern electronics, especially where durability is crucial, such as in THT solder RJ45 connectors, which are essential for reliable network connections. Additionally, Surface Mount Technology (SMT) is also gaining traction, complementing THT in various applications.

What Is THT Mounting?

Definition:

Through-Hole Technology (THT) refers to a method of mounting electronic components where component leads pass through drilled holes on a PCB and are then soldered on the opposite side. Components designed for THT often include resistors, capacitors, connectors, and integrated circuits in Dual In-Line Package (DIP) format.

Key Features:

Drilled Holes: Precise holes are mechanically drilled or laser-pierced through the PCB at designated pads.

Component Leads: Axial or radial leads of the component traverse the PCB thickness.

Soldering Side: Solder is applied to the underside (or solder side) of the board, creating a robust metallurgical bond.

Components and Processes in THT Through Hole Technology

Key Components in Through-Hole Technology

Through-hole technology relies on specific components that ensure durability and reliability in electronic assemblies. These components include resistors, capacitors, diodes, magenetics, connectors and transistors, which are often packaged as tht-packaged electronic components. Their leads are designed to pass through holes in printed circuit boards, enabling secure mechanical and electrical connections.

When working with tht-packaged electronic components, you’ll notice their versatility in applications like Programmable Logic Controllers (PLCs). These components play a critical role in industrial processes, ensuring operational efficiency and long-term performance.

THT Assembly Process: Step-by-Step

1. PCB Drilling

Drill File Generation: After circuit layout, the PCB design software (e.g., Altium, KiCad) exports a drill file (excellon format).

Drilling Operation: Automated CNC drills or laser machines create holes according to the drill file. Hole diameters typically range from 0.6 mm to 1.5 mm or larger, depending on component lead size.

2. Component Insertion

Manual Insertion: Operators place each component by hand—common for low-volume or prototype runs.

Automated Insertion Machines (Axial/Radial Inserters): Semi-automated inserters can feed resistors, capacitors, and leads to designated holes.

Orientation & Polarity: Ensure polarized components (e.g., electrolytic capacitors, diodes) are oriented correctly following the board’s silk-screen markings.

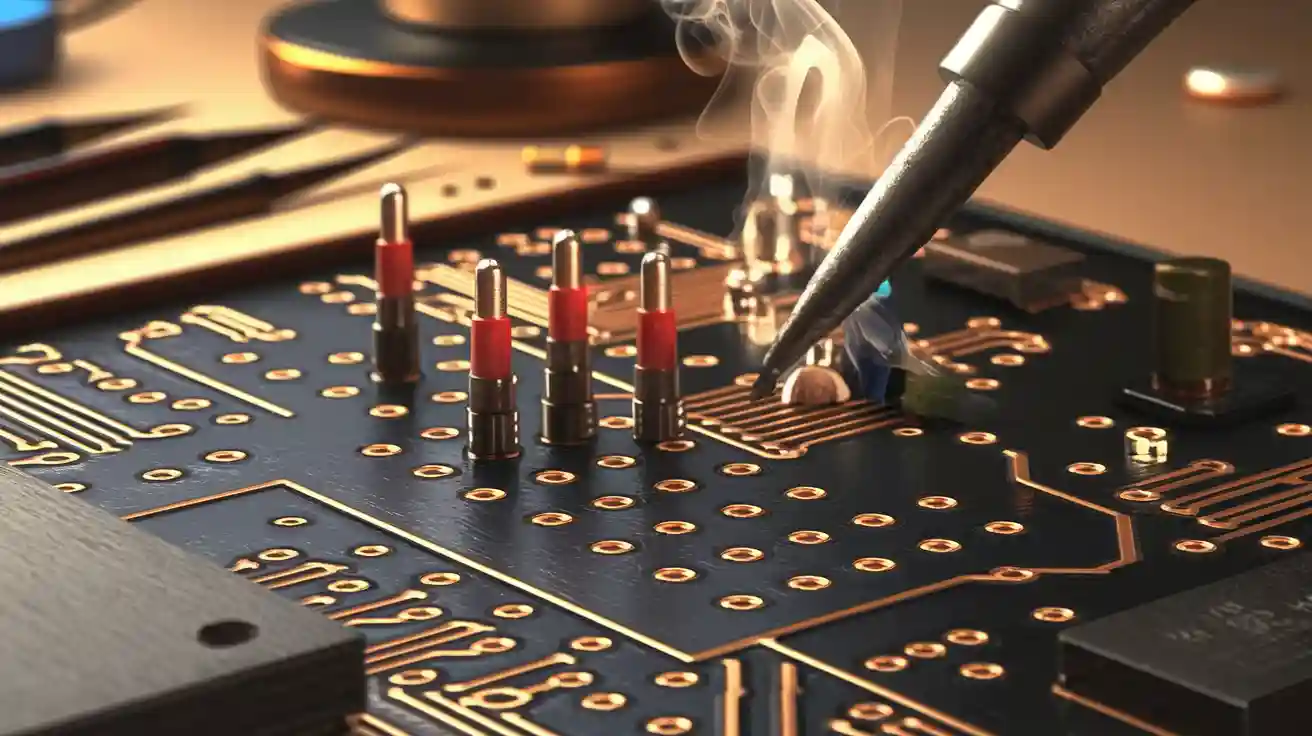

3. Wave Soldering / Selective Soldering

Wave Soldering: The assembled PCB passes over a molten solder wave. Surface tension pulls solder through the hole to form reliable joints on both sides.

Selective Soldering: For mixed-technology boards (THT+SMT), selective nozzles apply solder only to through-hole pins, preserving nearby SMT components.

4. Inspection & Quality Control

Visual Inspection: Check for solder bridges, cold joints, or misaligned leads.

Automated Optical Inspection (AOI): Modern AOI systems can verify hole fill, solder fillet quality, and correct component placement.

X-Ray Inspection: For critical or hidden joints (e.g., BGA components in reflowed assemblies), X-ray can detect voids, though this is more common for SMT.

Yield rates are a key indicator of the efficiency of the tht assembly process. For example, if 1,000 units are produced and 50 are defective, the yield rate is calculated as follows:

Yield Rate = (950 / 1,000) x 100 = 95%

A yield rate of 95% signifies high production efficiency, minimizing waste and ensuring quality. High yield rates are crucial for industries that rely on tht through hole technology, as they enhance profitability and reduce rework.

Best Practices for THT Assembly

To achieve optimal results in tht through hole technology, you should follow proven best practices for tht assembly. These practices ensure high-quality solder joints and minimize defects during the assembly process.

Best Practice | Description |

|---|---|

Automated Inspection Systems | Utilize machine vision and other automated inspection systems to detect defects with higher precision. |

Robotics in Production | Robotic systems bring consistency and reliability, reducing the error rate associated with manual labor. |

Internet of Things (IoT) | Connect machines, sensors, and quality control systems over IoT networks for real-time monitoring and data collection. |

Continuous Improvement | Implement a culture of ongoing enhancement in quality control processes to adapt to changing standards. |

Clear KPIs | Establish measurable Key Performance Indicators to track defect rates and production efficiency. |

Data Analytics | Use analytics to monitor quality metrics and identify trends in defects over time. |

Advantages and Disadvantages of Through Hole Technology

Advantages of THT

Mechanical Strength:

Because component leads go through the PCB, solder joints have greater strain relief—ideal for connectors, power components, and board edges.

Ease of Prototyping & Repair:

Technicians can desolder and replace through-hole parts more easily than SMT components, reducing repair time and cost in low-volume contexts.

High Current Capability:

Thicker leads and larger solder fillets allow THT parts to handle higher currents and power dissipation compared to many surface-mount equivalents.

Thermal Dissipation:

Through-hole components, particularly heat sinks and power regulators, can dissipate heat more effectively via larger solder fillets and metal-to-board contact.

Disadvantages of THT

Board Real Estate:

Through-hole parts occupy more space—both on the solder side and component side of the PCB—limiting component density.

Slower Assembly Speed:

THT assembly (especially manual insertion) is slower than SMT pick-and-place and reflow soldering, impacting production throughput in high-volume manufacturing.

Higher Drilling Costs:

Additional drilling steps add manufacturing time and cost. For PCBs with thousands of holes, setup and drill wear can be significant.

Limited Miniaturization:

As consumer electronics demand ever-smaller form factors, through-hole technology cannot compete with ultra-fine-pitch SMT packages.

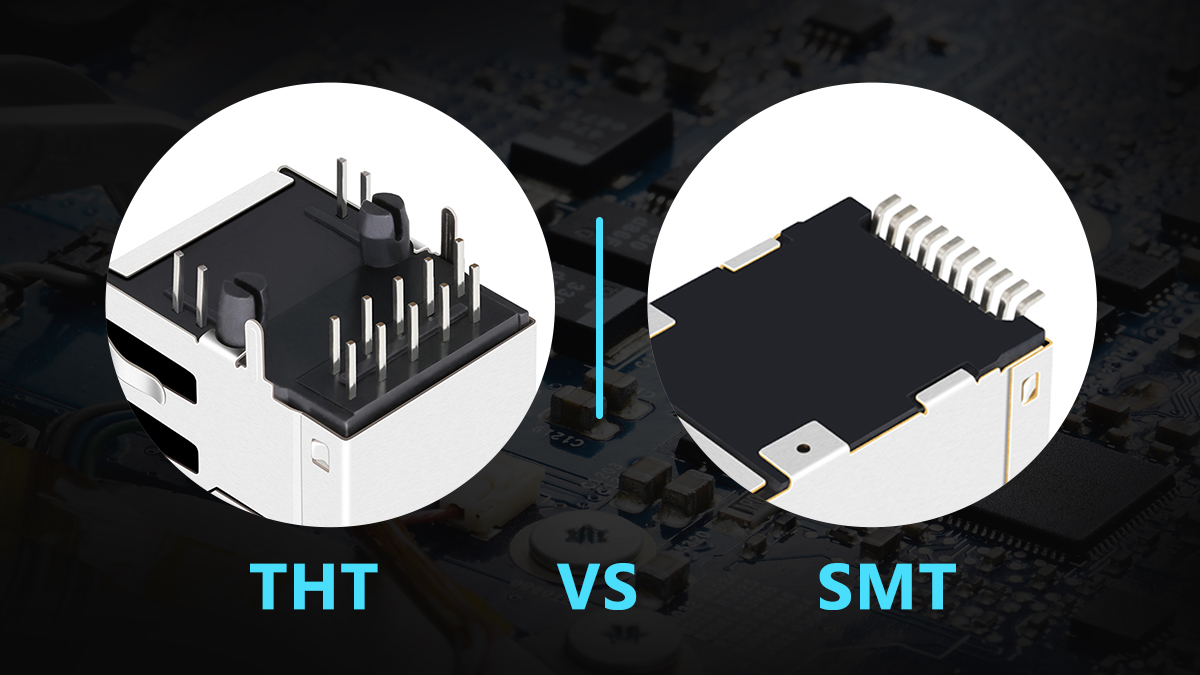

THT vs. SMT: A Comparison

Criteria | Through-Hole Technology (THT) | Surface-Mount Technology (SMT) |

|---|---|---|

Mechanical Stress | Excellent (ideal for connectors, large components) | Moderate (susceptible to vibration if not reinforced) |

Assembly Speed | Slower (manual/automated insertion + wave solder) | Faster (automated pick-and-place + reflow) |

Component Density | Lower (requires space for leads) | Higher (allows fine-pitch, multi-layer boards) |

Repair & Prototyping | Easier (hand soldering/desoldering) | More difficult (miniature joints, specialized rework tools) |

Cost per Unit (High Volume) | Higher (assembly time + drilling costs) | Lower (fewer secondary operations) |

Applications and Recent Trends in Through Hole Technology

THT Applications: Why Choose Through-Hole?

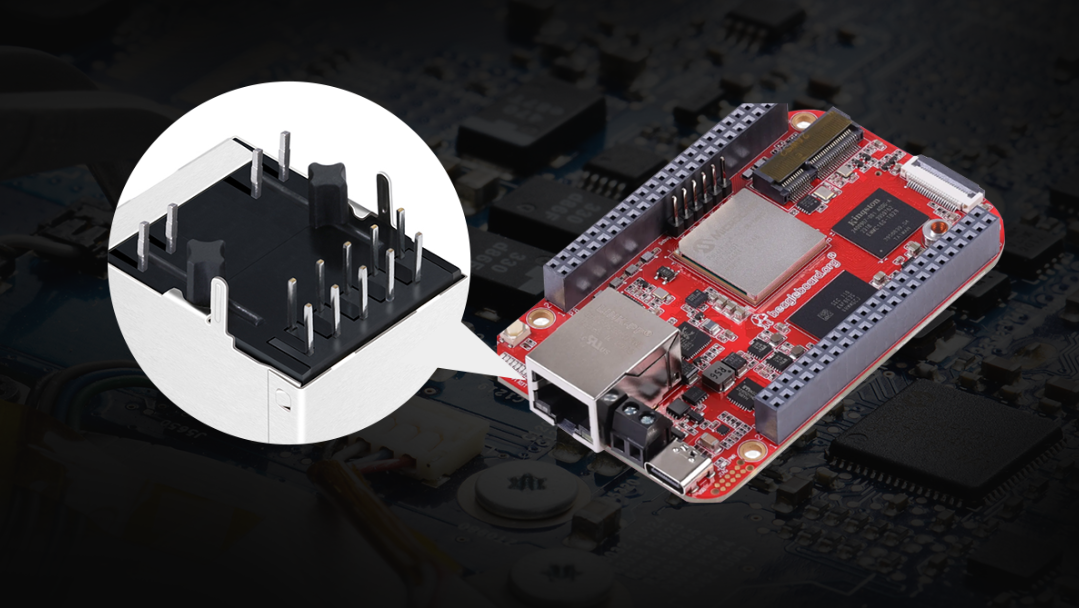

Connectors & Switches:

Bulkhead connectors (e.g., USB Type-A, HDMI) and mechanical switches require robust solder joints. LINK-PP’s THT Solder RJ45 Connector exemplifies a rugged, integrated Ethernet connector designed specifically for THT mounting—offering superior mechanical retention and reliable signal integrity for industrial networking applications.

Power Electronics:

High-power resistors, inductors, and transformers are frequently through-hole due to their large lead diameters and heat dissipation needs.

Harsh Environment Equipment:

Defense, aerospace, automotive, and industrial controllers often require through-hole parts to survive extreme vibration, shock, or temperature cycles.

Prototyping & Hobbyist Boards:

DIY electronics platforms, prototyping boards, and academic labs favor through-hole components for ease of hand-soldering and educational clarity.

Recent Trends in Through-Hole Technology

Technological advancements are influencing how THT components are designed and integrated. Digital technologies are enhancing production efficiency and enabling smarter manufacturing processes. For example, automated inspection systems and robotics are improving precision and reducing error rates. These innovations are expanding the scope of through-hole technology, ensuring its relevance in high reliability applications.

The global market for THT through hole technology continues to grow, driven by demand from industries like aerospace and defense. As new products emerge, you’ll see more applications leveraging the durability and reliability of THT components. These trends underscore the importance of staying updated on recent developments in through hole technology.

Conclusion

Through-Hole Technology (THT) continues to be an indispensable part of PCB assembly, particularly for applications demanding mechanical robustness, high current handling, and simple field servicing. By understanding the THT process, benefits, and trade-offs—alongside modern hybrid assembly strategies—designers can make informed decisions about when to specify through-hole components. For industries relying on industrial-grade connectors, the reliability of a THT-mounted device is unmatched.

FAQ

What is the main difference between THT and SMT?

THT involves inserting component leads into drilled PCB holes, while SMT mounts components directly onto the PCB surface without drilling.

Can THT and SMT coexist on one PCB?

Yes. Mixed-technology boards use SMT for compact ICs and THT for connectors/transformers, leveraging both advantages.

What types of components are commonly used in THT?

THT typically uses resistors, capacitors, diodes, and transistors. These components have leads designed for insertion into PCB holes.

What makes THT suitable for high-stress environments?

THT creates strong mechanical bonds by soldering leads through PCB holes. This ensures durability under vibrations and physical stress.