Surface Mount Technology (SMT) is a cutting-edge method for assembling electronic circuits by mounting components directly onto the surface of printed circuit boards (PCBs). As the dominant technology in modern electronics manufacturing, SMT has revolutionized industries by enabling smaller, lighter, and more reliable devices compared to traditional through-hole technology (THT). This glossary explores the key concepts, processes, and advantages of SMT, with insights into its applications in products like LINK-PP's SMT RJ45 Connectors and SMT LAN Transformers.

SMT achieves high-density layouts, making electronics lighter and thinner while improving performance.

What Is Surface Mount Technology?

Definition of SMT

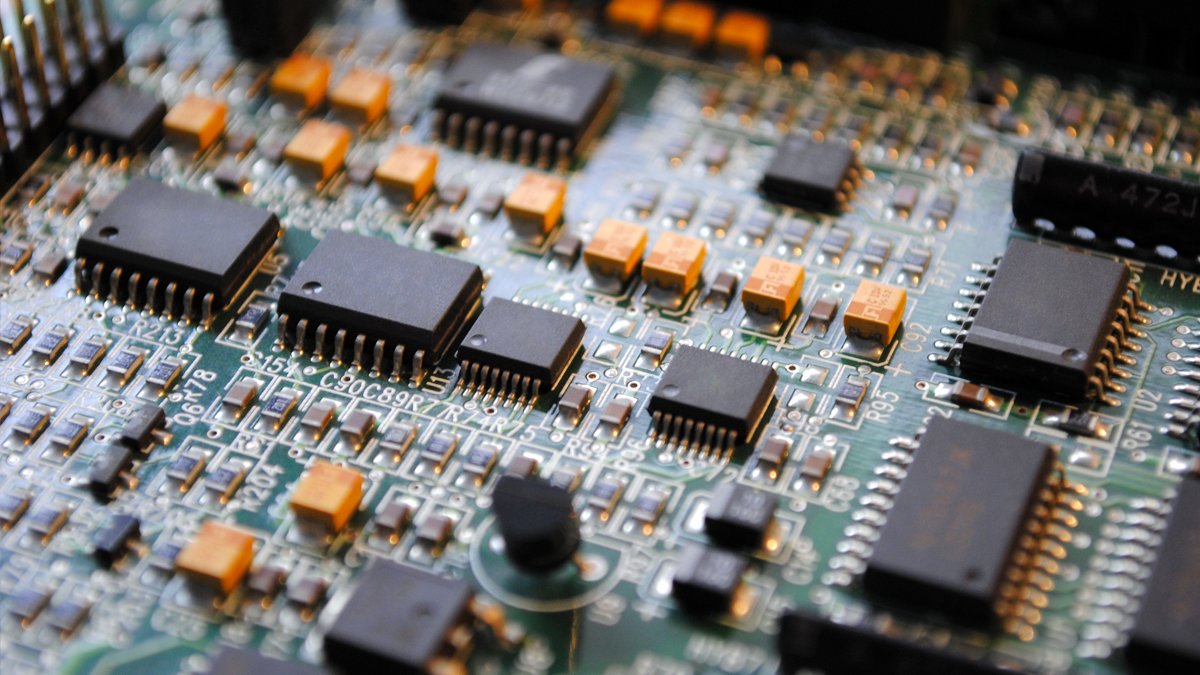

SMT stands for Surface Mount Technology. It is a method for producing electronic circuits in which components (called surface-mount devices, or SMDs) are mounted directly onto the surface of a printed circuit board (PCB) instead of being inserted through holes. In SMT, components have short leads or none at all (for example, chip resistors, capacitors, or balls in a BGA package) and are soldered onto copper pads on the PCB. This contrasts with older through-hole technology, which required drilling holes and led to lower packing density. The SMT approach enables more components to fit on a given board area and supports automated assembly, making modern electronics smaller and more cost-effective.

There some other terms often associated with surface-mount technology (SMT):

SMA – Surface-mount assembly

SMC – Surface-mount components

SMP – Surface-mount package

SME – Surface-mount equipment

How SMT Works – Process Overview

SMT assembly is usually performed in a multi-stage, automated line. The major steps include:

Solder Paste Printing: A stencil printer applies solder paste to PCB pads. Consistent paste deposition is vital for reliable connections.

Component Placement: High-speed pick-and-place machines position SMDs like resistors, ICs, and LINK-PP's SMT LAN Transformers with micron-level accuracy.

Reflow Soldering: PCBs pass through a reflow oven, melting solder paste to form permanent electrical bonds. Temperature profiling ensures defect-free joints.

Inspection & Testing: Automated optical inspection (AOI), X-ray systems, and functional testing validate solder quality and component alignment.

Rework: Defective boards undergo repair using specialized tools to replace faulty components.

Advantages and Limitations

SMT offers significant benefits over traditional assembly:

Higher density and miniaturization: Components are smaller and mounted on both sides of the PCB, allowing far more parts in a given area. This enables compact, lightweight designs.

Automated, cost-effective production: Pick-and-place machines and reflow soldering speed up assembly for large volumes. The production setup is faster (no drilling holes) and less labor-intensive, lowering per-unit costs.

Improved performance: Shorter leads and smaller packages reduce parasitic inductance and capacitance, improving high-frequency signal performance. Surface tension during reflow also helps self-align parts for better solder joints.

However, SMT also has some limitations:

Equipment and skill requirements: High-precision SMT assembly requires expensive machines (stencil printers, pick-and-place robots, reflow ovens) and trained operators. Initial capital and repair costs are higher than for through-hole assembly. Manual soldering or rework is difficult for tiny SMD packages.

Mechanical and thermal stress: SMD parts use very small solder joints and are not as robust against mechanical strain. Large or heavy components (such as big transformers or heat-sinked power devices) generally still use through-hole mounting for strength. Thermal cycling can stress SMD joints, and boards with many tiny parts can be harder to rework and inspect.

Assembly reliability: Less solder volume and ultra-fine pitch increase the chance of defects like solder bridges or voids. Also, the tiny markings on SMD parts make hand identification and troubleshooting harder.

Common Applications of SMT

Surface-mount technology plays a vital role in the production of modern electronic devices. Its ability to support compact designs and high-speed assembly makes it indispensable across various industries. Here are some of the most common applications of SMT:

Automotive Electronics: SMT enhances engine performance and powers in-car entertainment systems.

Medical Devices: It is used in patient monitoring systems and diagnostic tools.

Communication Devices: Routers, modems, and networking equipment rely on SMT for efficient functionality.

Gaming Consoles: Devices like PlayStation and Xbox use SMT to deliver seamless gaming experiences.

Wearable Technology: Smartwatches and fitness trackers benefit from SMT's compactness.

Industrial Equipment: Control panels and automation systems depend on SMT for reliability.

Aerospace and Defense Systems: SMT is crucial for applications where space and weight are critical.

Home Automation Devices: Smart thermostats and security cameras utilize SMT for advanced features.

Audio Equipment: Soundbars and audio receivers achieve better performance with SMT.

Renewable Energy Systems: Solar inverters and wind turbine control systems incorporate SMT for efficiency.

Consumer Electronics: Devices like MP3 players and portable gaming systems rely on SMT for their compact designs.

As one example, LINK-PP offers specialized surface-mount modules like SMT RJ45 Connector and SMT LAN Transformer for Ethernet interfaces. These components illustrate how SMT is applied in network hardware: the RJ45 connector attaches to the PCB surface while a paired SMT lan transformer provides the required isolation and filtering.

Comparing SMT to Other Technologies

SMT vs. Through-Hole Technology (THT)

When comparing SMT to Through-Hole Technology (THT), you’ll notice significant differences in efficiency and design flexibility. SMT allows components to be mounted directly onto the PCB surface, enabling smaller and lighter designs. THT, on the other hand, requires drilling holes into the PCB, which limits component density and increases production time.

Here’s a quick comparison:

Feature | Surface Mount Technology (SMT) | Through-Hole Technology (THT) |

|---|---|---|

Component Size | Smaller and lighter | Larger |

Component Density | Higher | Lower |

PCB Manufacturing | Double-sided | Single-sided |

Automation | High (increased automation) | Low (manual intervention needed) |

Production Speed | Faster | Slower |

Unit Cost | Lower | Higher |

SMT’s ability to support double-sided PCB manufacturing and automated processes makes it ideal for high-volume production. THT, however, remains useful for applications requiring robust mechanical connections, such as industrial equipment.

SMT vs. Chip-on-Board (COB)

Chip-on-Board (COB) technology offers another alternative to SMT. COB involves mounting bare semiconductor chips directly onto the PCB and encapsulating them with epoxy. While COB provides high component density and efficient production, SMT excels in versatility and automation.

Technology | Advantages | Disadvantages |

|---|---|---|

SMT | High production efficiency, component density, suitable for high-frequency applications | Susceptible to thermal stress, initial investment in equipment |

COB | High component density, efficient production | Similar challenges as SMT in terms of thermal stress and assembly quality |

You’ll find COB used in applications like LED lighting, where compact designs are essential. SMT, however, dominates industries requiring high-speed assembly and flexible designs.

Summary

SMT = Surface Mount Technology: A PCB assembly method where components solder directly onto the board surface.

Evolution: Developed in the 1960s and mainstream by the 1990s, SMT largely replaced through-hole for most electronics. Modern SMT includes tiny chip packages and BGAs for high density.

Process: Typically involves solder paste printing, automated pick-and-place of components, then reflow soldering in an oven. This automated line achieves fast, repeatable assembly.

Advantages: Enables higher component density, smaller/lightweight products, and efficient mass production. Improved electrical performance (lower inductance) is another benefit.

Limitations: Requires costly equipment and skilled operators. SMDs have smaller solder joints (less robust) and are harder to hand-solder or inspect. Very large or high-power components often still use through-hole.

Applications: SMT is used in virtually all modern electronics – from smartphones and PCs to cars, medical devices, and telecom equipment. For instance, surface-mount Ethernet connectors and magnetics (like LINK-PP’s SMT RJ45 Connector and SMT LAN Transformer) are common SMT components in networking hardware. These examples highlight how SMT enables compact, high-performance circuit designs.