A surface-mount device (SMD) is a small electronic component that attaches directly to the surface of a circuit board. People often confuse a surface-mount device (SMD) with surface mount technology, but SMD refers to the part, whileSMT describes the process. Surface-mount devices make it possible to build compact and reliable gadgets. For example, a surface mount device like a LINK-PP RJ45 Connector or a LINK-PP LAN Transformer helps modern electronics work better. SMDs allow engineers to design smaller products without losing performance.

Key Takeaways

Surface-mount devices (SMD) are small electronic parts that attach directly to circuit boards, enabling smaller and more powerful gadgets.

SMDs differ from surface mount technology (SMT); SMDs are the parts, while SMT is the process that places and solders these parts on boards.

Using SMDs allows engineers to design compact, lightweight devices with many functions packed closely together, improving performance and reducing costs.

There are three main types of SMD components: passive (resistors, capacitors), active (diodes, transistors), and electromechanical (switches, connectors).

SMT assembly uses machines to place SMDs quickly and accurately, speeding production and ensuring high-quality electronic products.

What Is a Surface-Mount Device (SMD)

SMD Definition

A Surface-Mount Device (SMD) is an electronic component that is mounted directly onto the surface of a printed circuit board (PCB). Unlike through-hole components, SMDs don’t require drilling holes in the PCB, making them ideal for high-density and miniaturized electronic designs.

Surface-mount technology (SMT) allows for compact designs, improved electrical performance, and efficient mass production — making it the backbone of today’s high-performance electronics, from consumer gadgets to telecom infrastructure.

Note: SMT is the process, while the surface-mount device (SMD) is the component. This distinction helps engineers choose the right tools and parts for each project.

Common SMD Component Types

Surface-mount devices span a wide range of passive and active components. Below is a quick overview of the most common SMD types used in modern electronic assemblies:

Component | Function |

|---|---|

SMD Resistors | Regulate voltage and limit current in circuits. |

SMD Capacitors | Filter noise, stabilize voltage, and decouple signals. |

SMD Magnetics | Provide EMI suppression and signal isolation in communication lines. |

SMD Transformers | Enable signal conversion and electrical isolation in Ethernet and telecom applications. |

SMD LEDs | Serve as status indicators directly on PCBs or within integrated connectors. |

Key Features

A surface mount device offers several important features that make it popular in electronics today. These features help engineers build smaller, faster, and more reliable products.

Miniature Size: Each surface mount device is much smaller than older components. This allows more SMD parts to fit on a single circuit board.

Lightweight: The SMD design reduces the weight of the electronic component, which is important for portable devices.

High Component Density: Engineers can place many smd parts close together. This increases the number of functions on a single board.

No or Short Leads: Most SMD parts have very short or no leads. This makes assembly faster and reduces the risk of errors.

Variety of Packages: SMDs come in many package types, such as SOT-23 for small transistors, DPAK for power parts, and QFP or BGA for integrated circuits. These packages help with heat control and save space.

Improved Performance: Shorter connections on the circuit board mean less electrical resistance and better signal quality.

Automated Assembly: Machines can quickly place and solder each surface mount device. This speeds up production and lowers costs.

SMD Components in Networking: LINK-PP’s Expertise

In high-speed networking and telecom systems, SMD magnetic components play a critical role in ensuring signal integrity, isolation, and compliance with EMI regulations. One of the standout components in this category is the LINK-PP LP72432ANL, a compact and high-performance LAN transformer designed for 2.5G Ethernet applications.

🔹 Featured Product: LINK-PP LP72432ANL

Type: 2.5G Base-T LAN Transformer (SMD)

Standards: IEEE 802.3bz compliant, PoE+ capable

Features: Compact SMD design, 1500Vrms isolation, optimized for 2.5 Gigabit Ethernet

Applications: Smart routers, access points, IP surveillance systems

Explore full specs:

👉 LP72432ANL 2.5G Base-T SMD LAN Transformer | LINK-PP

📄 Download Drawing PDF

This transformer’s surface-mount packaging allows for high-density PCB layout while maintaining excellent signal performance, making it ideal for modern Ethernet designs where performance and size are both crucial.

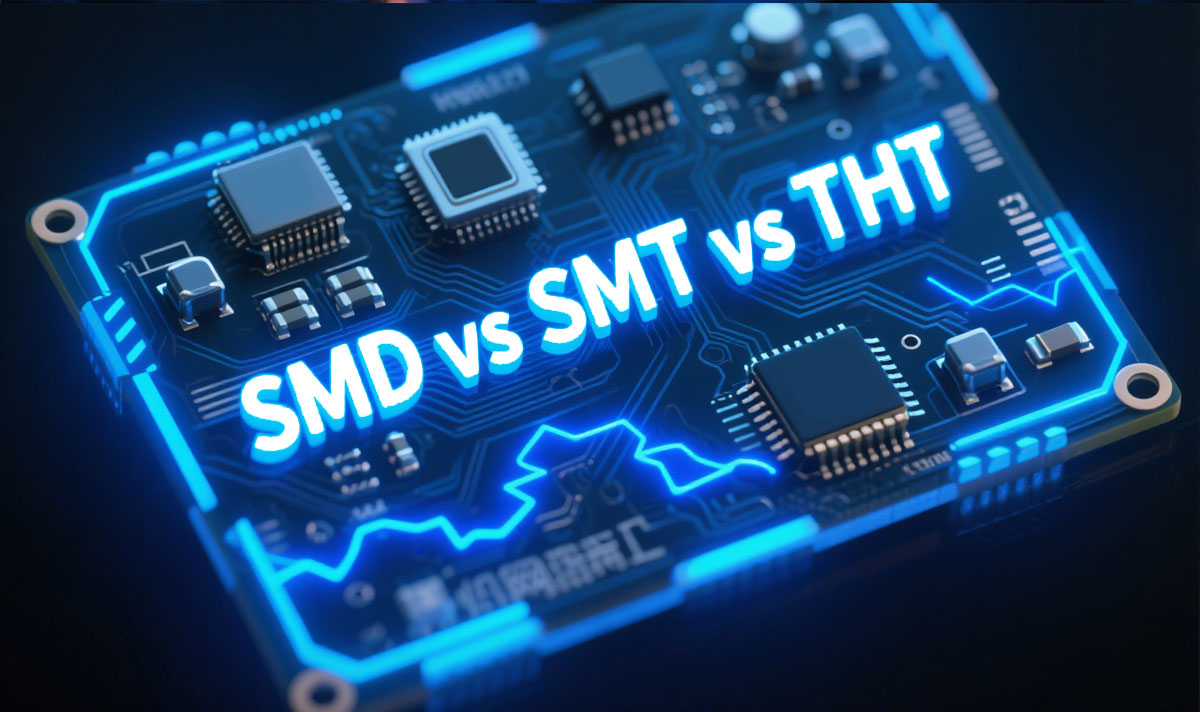

SMD vs. SMT vs. THT: Understanding the Differences

When choosing components for a circuit board, it’s essential to distinguish between SMD, SMT, and THT, as each term refers to a different concept in assembly or packaging:

Term | Meaning | Function |

|---|---|---|

SMD (Surface-Mount Device) | A physical component (resistor, transformer, connector) designed for mounting on the PCB surface | Describes the component |

SMT (Surface-Mount Technology) | The manufacturing method of placing SMDs on the surface of the PCB | Describes the assembly process |

THT (Through-Hole Technology) | A method where component leads pass through drilled holes in the PCB and are soldered from underneath | Typically used for large or high-stress components |

SMD Advantages and Disadvantages

Benefits of SMDs

SMDs support automation in factories. Machines can place and solder each SMD quickly, which reduces labor costs and speeds up production.

Electrical performance improves with SMD parts. Shorter leads mean less unwanted resistance and better signal quality. This is important for high-frequency circuits.

SMD help lower material and handling costs. Smaller boards use less space and fewer materials.

Industry studies show that SMD technology enables miniaturization and supports faster, more reliable assembly.

Tip: SMD make it possible to build smartphones, tablets, and wearables that fit in a pocket.

Limitations

SMDs also have some drawbacks. Their small size can make repair or replacement difficult. Technicians need special tools and skills to handle these tiny parts. If a SMD is misaligned or not soldered correctly, it may fail during use.

SMD do not work well in high-power or high-voltage applications. Through-hole components perform better in these cases.

Mechanical strength can be a concern. SMDs may not survive strong vibrations or shocks, which are common in automotive or industrial settings.

Factories must invest in expensive machines for smd assembly. This increases the initial cost for manufacturers.

Soldering defects, such as bridges or voids, can occur more easily with SMD parts.

LINK-PP’s SMD Solutions: Designed for Performance & Scalability

LINK-PP offers a wide portfolio of SMD magnetic components and integrated connectors, engineered to meet the evolving demands of next-generation Ethernet and 5G applications. All products are:

RoHS & REACH compliant

ISO 9001 certified

Backed by custom design support

Whether you're building a compact IoT gateway or a ruggedized industrial router, LINK-PP has SMT-compatible magnetic jacks tailored for your needs.

See Also

Exploring The Meaning And Importance Of SMT Technology