In the intricate world of fiber optic communication, data travels at the speed of light. But how do we efficiently distribute this luminous data stream to multiple destinations? Enter the unsung hero of many Passive Optical Networks (PON): the Fused Biconical Taper (FBT) Splitter.

Whether you're a network engineer, a project manager, or simply curious about the technology that powers your high-speed internet, understanding FBT splitters is crucial. This guide will delve into what they are, how they work, their key advantages, and how to choose the right one for your project. We'll also explore their synergy with essential components like optical modules.

📌 Key Topics We'll Cover:

What is an FBT Splitter and How Does it Work?

FBT Splitter vs. PLC Splitter: A Detailed Comparison

Common Applications and Use-Cases

The Critical Link: FBT Splitters and Optical Modules

Choosing the Right FBT Splitter for Your Network

📝 What is an FBT Splitter? The Simple Science of Splitting Light

At its core, an FBT splitter is a passive optical device that takes a single optical input signal and divides it into two or more output signals. The technology is elegantly simple yet highly effective.

The manufacturing process involves fusing two or more optical fibers together by applying heat and then stretching them in a controlled, tapering fashion. This "fused biconical taper" region causes the light propagating in the input fiber to couple into the other fibers. The splitting ratio is determined by the length of the fused section and the tension applied during the tapering process.

This method is particularly well-suited for creating low-ratio splitters, such as 1x2 and 1x4 configurations, and is a cost-effective solution for many standard applications.

📝 FBT vs. PLC Splitter: Which One is Right for Your Project?

When planning a fiber network, one of the most common dilemmas is choosing between FBT and Planar Lightwave Circuit (PLC) splitters. Both are excellent, but they serve different purposes. The best choice often depends on your specific requirements for split count, operating wavelength, and environmental stability.

Here’s a quick comparison to help you decide:

Feature | FBT (Fused Biconical Taper) Splitter | PLC (Planar Lightwave Circuit) Splitter |

|---|---|---|

Technology | Fusing and tapering of fibers | Lithography on a silica glass substrate |

Split Ratios | Common: 1x2, 1x3, 1x4 (Custom ratios possible) | Standard: 1x8, 1x16, 1x32, 1x64 |

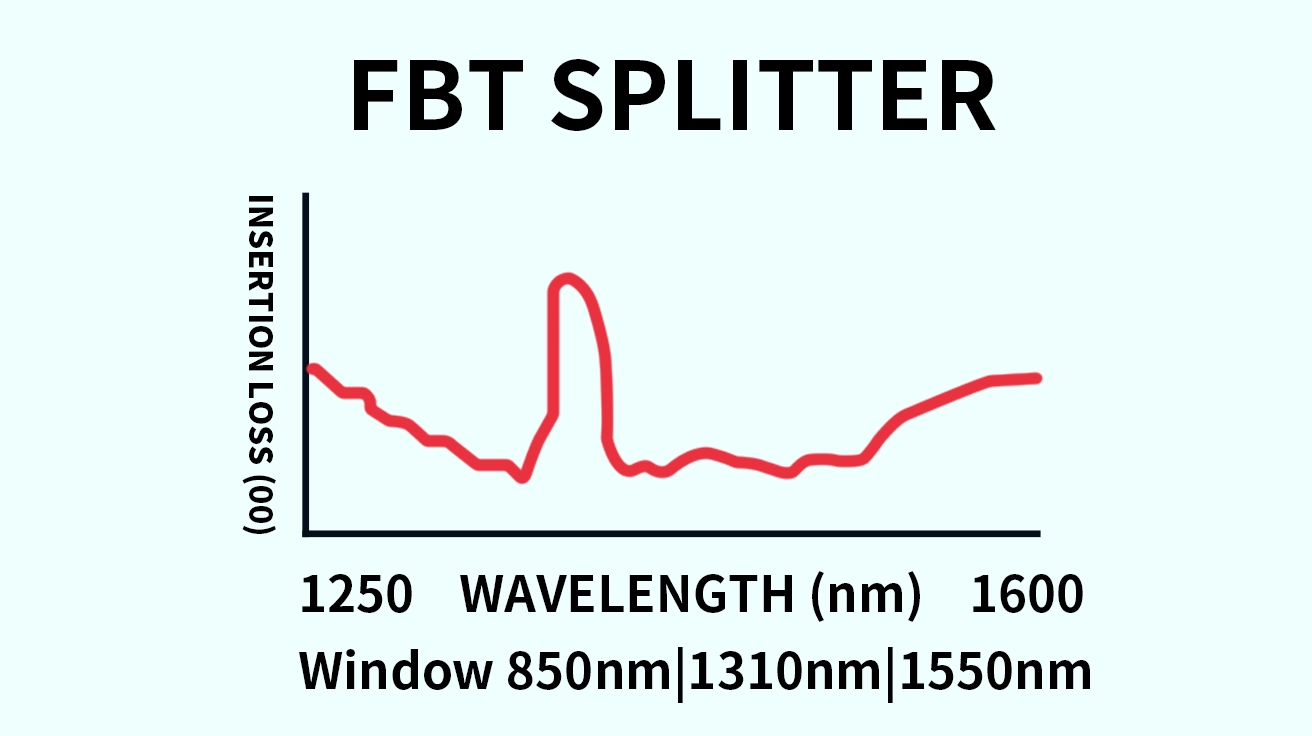

Operating Wavelength | Often limited (e.g., 1310nm, 1550nm) or Wideband (1260-1650nm) | Wideband (1260-1650nm) |

Uniformity | Lower; output power can vary between ports | High; very consistent signal across all output ports |

Size Footprint | Larger for higher split counts | Compact, even for high split counts |

Cost | More cost-effective for lower split ratios | Higher initial cost, cost-efficient at high split counts |

Best For | FTTH applications, CATV, passive optical networks where lower splits are needed. | Dense PON networks (GPON, XGS-PON), data centers requiring high, uniform splits. |

📢 Pro Tip: For many Fiber-to-the-Home (FTTH) deployments that require a simple, reliable, and economical split close to the subscriber, an FBT splitter is often the perfect fit. Its ability to handle custom split ratios also makes it ideal for specialized monitoring systems.

📝 Where Are FBT Splitters Used? Key Applications

The versatility of FBT splitters makes them a cornerstone in various telecommunication and networking scenarios:

Passive Optical Networks (PON): In architectures like GPON or EPON, FBT splitters are used in the outside plant or building basements to distribute a single signal from the central office to multiple homes and businesses.

CATV (Cable Television) Signal Distribution: They are instrumental in splitting the downstream RF video signal over fiber to numerous subscribers.

Network Monitoring: FBT splitters can tap off a small percentage of the signal (e.g., 1% or 5%) for testing and monitoring purposes without significantly disrupting the main data path.

Local Area Networks (LAN): Used within campus or enterprise networks to distribute optical links to different departments or floors.

📝 The Perfect Partner: Integrating FBT Splitters with Optical Modules

A fiber network is an ecosystem, and the splitter is just one part of the chain. For the system to function flawlessly, the splitter must work in harmony with the optical modules (transceivers) at either end of the link.

Optical modules, like the popular SFP and SFP+ form factors, are responsible for converting electrical signals to light and vice versa. When you introduce an FBT splitter into the network, it introduces insertion loss—the inevitable weakening of the signal as it's divided.

This is where the link budget calculation becomes critical. You must ensure that the power budget of your optical module can overcome the total loss from the fiber length, connectors, and the splitter itself. Using a low-quality splitter can push your optical module beyond its receiver sensitivity, leading to data errors and network downtime.

For instance, when deploying a FBT Splitter in a point-to-multipoint setup, pairing it with a high-performance, reliable optical module is non-negotiable. A compatible module like the LINK-PP SFP-10G-LR transceiver offers the necessary power budget and stability to ensure a robust and error-free connection, even after accounting for splitter-induced loss. This synergy guarantees that your network delivers on its promise of speed and reliability.

📝 How to Select a High-Quality FBT Splitter

Not all FBT splitters are created equal. To ensure network longevity and performance, consider these factors:

Split Ratio & Configuration: Confirm the number of inputs and outputs you need (e.g., 1x2, 2x4).

Insertion Loss: This is the most critical specification. Ensure the vendor provides guaranteed maximum insertion loss values.

Wavelength Range: Choose a standard dual-window (1310/1550nm) or a wideband version (1260-1650nm) for future-proofing.

Uniformity: For applications requiring equal power to all outputs, seek a splitter with high uniformity.

Directivity & Return Loss: High directivity and low return loss minimize back-reflections that can interfere with the light source.

Packaging and Reliability: Look for robust packaging (e.g., ABS box, steel tube, rack-mount) that can withstand the intended environment (temperature, humidity). Reputable manufacturers like LINK-PP subject their splitters to rigorous testing to ensure they meet telecom-grade standards.

🚀 Ready to Optimize Your Fiber Network?

Choosing the right passive components is the foundation of a high-performance network. FBT splitters offer a proven, reliable, and cost-effective solution for a wide range of splitting applications.

If you're designing a new network or upgrading an existing one, the expert team at LINK-PP is here to help. We provide a full range of high-quality FBT splitters, PLC splitters, and compatible optical transceivers, all backed by comprehensive technical support and a lifetime warranty.

👉 [Contact our experts today] for a free consultation and let us help you build a faster, more reliable fiber network!

📝 FAQ

What is the main use of an FBT splitter?

You use an FBT splitter to divide one optical signal into several paths. This helps you send data to different devices in a fiber network.

What makes FBT splitters cost-effective?

You find FBT splitters cost less because they use simple materials and an easy manufacturing process. This makes them a good choice for small networks.

What splitting ratios can you choose with FBT splitters?

You can pick from several splitting ratios, like 50:50 or 70:30. This lets you control how much signal each output receives.

What are the main limits of FBT splitters?

You may see more signal loss with many outputs. FBT splitters also work best when temperatures stay steady.

What is the difference between FBT and PLC splitters?

You get FBT splitters for simple, low-cost jobs with few outputs. PLC splitters work better for large networks and give more stable performance.