Have you ever wondered how a massive wind turbine blade can sense structural stress, or how temperatures are monitored deep within a power plant? The answer often lies in a remarkable technology hidden inside a hair-thin optical fiber: Fiber Bragg Grating (FBG).

In this comprehensive guide, we'll demystify FBG technology. We'll explore its fundamental principles, how it's manufactured, its wide-ranging applications, and why it's a superior choice for modern sensing and communication systems. We'll also touch upon its role in advanced optical transceivers.

🌐 Key Takeaways

Fiber Bragg grating sensors can measure strain and temperature changes well. They help check the safety of bridges and machines.

These sensors reflect only certain colors of light. This lets them notice even small changes around them.

Fiber Bragg grating sensors are dependable and not bothered by electrical noise. They work in hard places where other sensors might stop working.

Multiplexing lets many sensors go on one fiber. This makes it easier and faster to watch over big areas.

Using fiber Bragg grating sensors helps keep things safe and working right. People use them in factories and to watch the environment.

🌐 The Core Principle: A "Mirror" Inside a Fiber

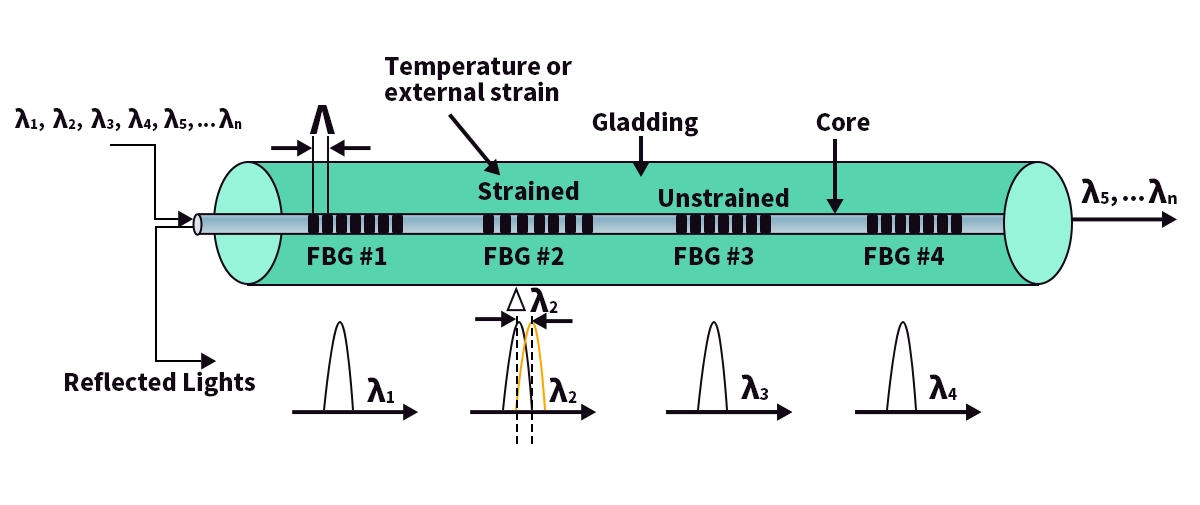

At its heart, a Fiber Bragg Grating is a microscopic periodic perturbation of the refractive index within the core of an optical fiber. Think of it as a series of tiny, parallel mirrors etched into the glass.

When broad-spectrum light is sent down the fiber, this special grating acts as a selective filter. It reflects a very specific wavelength of light, known as the Bragg Wavelength (λ₆), while transmitting all others.

The fundamental equation governing this is:

λ₆ = 2nΛ

Where:

λ₆ is the Bragg wavelength (the reflected wavelength).

n is the effective refractive index of the fiber core.

Λ (Lambda) is the period of the grating.

This simple equation is the key to FBG's sensing power. Any external factor like strain (stretching or compression), temperature, or pressure that changes either 'n' or 'Λ' will cause a direct, measurable shift in the Bragg wavelength. By precisely measuring this shift, we can determine the exact magnitude of the physical change affecting the grating.

🌐 How Are FBG Sensors Manufactured?

Creating these intricate internal mirrors requires precision. The most common method is the phase mask technique.

The Setup: A special phase mask (a photolithographic grating) is placed in front of a photosensitive optical fiber.

The "Writing" Process: An intense ultraviolet (UV) laser beam is shone through the mask.

Permanent Alteration: The UV light interferes through the mask, creating a periodic pattern of intense and weak light on the fiber core. This exposure permanently increases the refractive index in the bright regions, "writing" the grating into the fiber.

This process allows for the creation of highly consistent and reliable FBG sensors, which is crucial for applications demanding high accuracy, such as structural health monitoring solutions and distributed sensing systems.

🌐 Key Advantages of FBG Technology: Why Choose It?

FBG sensors have revolutionized measurement in harsh and critical environments. Here’s a comparison of why they often outperform traditional electronic sensors:

Feature | FBG Sensors | Traditional Electronic Sensors |

|---|---|---|

Immunity to EMI | ✅ Excellent (Light-based) | ❌ Susceptible to interference |

Form Factor | Small, lightweight, flexible | Often bulkier |

Multiplexing | ✅ High (Many sensors on one fiber) | ❌ Complex wiring for each sensor |

Corrosion Resistance | ✅ Excellent (Glass) | ❌ Can corrode in harsh environments |

Long-Distance | ✅ Works over kilometers | ❌ Limited signal range |

This makes FBG technology ideal for real-time condition monitoring in electrically noisy industrial settings and for ensuring aviation and aerospace safety through embedded sensing in composite materials.

🌐 Real-World Applications of FBG Sensing

The unique benefits of FBG translate into powerful solutions across numerous industries:

Civil Engineering & Infrastructure: Monitoring bridges, tunnels, dams, and historical buildings for stress, strain, and deformation.

Energy: Temperature monitoring in power transformers and wind turbine blade load sensing.

Aerospace: Embedding sensors in aircraft wings and fuselages to monitor structural integrity.

Medical: Developing advanced shape-sensing needles and catheters for minimally invasive surgery.

Oil & Gas: Downhole pressure and temperature sensing in extreme environments.

🌐 The FBG Connection: Wavelength Stability in Optical Transceivers

You might be wondering, what does FBG have to do with data communication? The answer lies in one of its earliest and most critical applications: stabilizing laser diodes in optical transceivers.

Lasers in transceivers can drift in wavelength with temperature and age, causing signal degradation. An internal FBG acts as a highly stable external cavity mirror, locking the laser's output to a specific, precise wavelength defined by the grating itself. This is essential for Dense Wavelength Division Multiplexing (DWDM) systems, where dozens of channels must remain perfectly aligned to prevent crosstalk.

For network engineers seeking reliable and high-performance components, choosing transceivers with stable laser sources is non-negotiable. For instance, the high-performance LINK-PP 100G QSFP28 transceiver leverages advanced laser technology to ensure superior signal integrity and low power consumption for demanding data center and telecom applications. When evaluating your high-speed optical transceiver requirements, considering the underlying technology that guarantees wavelength stability is a key step.

🌐 Conclusion: The Future is Written in Light

Fiber Bragg Grating is a versatile and powerful technology that turns a simple optical fiber into a precise sensing and communication tool. Its immunity to EMI, multiplexing capability, and ruggedness make it the go-to solution for smart infrastructure, advanced industrial monitoring, and reliable high-speed data links.

As the demand for data and intelligent monitoring grows, the role of FBG will only become more prominent, paving the way for safer structures, more efficient industries, and faster networks.

🌐 FAQ

What is the main purpose of a fiber Bragg grating sensor?

You use a fiber Bragg grating sensor to measure strain and temperature. The sensor helps you find changes in structures or machines. It gives you clear data using light.

What makes fiber Bragg grating sensors different from regular sensors?

Fiber Bragg grating sensors use light instead of electricity. You get accurate readings. The sensors do not react to electrical noise. You can use them in places where regular sensors might fail.

What types of environments can you use fiber Bragg grating sensors in?

You can use fiber Bragg grating sensors in wet, hot, or dirty places. The sensors work well in tough conditions. You can trust them for outdoor, industrial, or underground monitoring.

What does the Bragg wavelength tell you?

The Bragg wavelength shows you if the fiber is stretched or heated. You watch this wavelength to know what is happening. A change means there is strain or temperature change.

What are some common uses for fiber Bragg grating sensors?

You find fiber Bragg grating sensors in bridges, tunnels, factories, and pipelines. The sensors help you monitor safety, spot damage, and check for leaks. You use them to keep things working well.