In modern industrial automation, real-time data exchange is essential for achieving fast, synchronized, and highly reliable control. EtherCAT—one of the leading Industrial Ethernet technologies—achieves its exceptional performance through several architectural innovations. Among these, the FMMU (Fieldbus Memory Management Unit) plays a central role.

This article provides a clear, technically accurate explanation of what the FMMU is, why it matters, and how it enables EtherCAT to deliver microsecond-level real-time communication. We also introduce how LINK-PP’s SFP fiber transceiver modules seamlessly support high-speed EtherCAT networks.

1. What Is the FMMU in EtherCAT?

FMMU (Fieldbus Memory Management Unit) is a hardware mechanism inside each EtherCAT slave device that maps logical process data addresses from the EtherCAT Master to the physical memory addresses of individual slave nodes.

In simple terms:

The FMMU allows the EtherCAT Master to access scattered data across multiple slave devices as if it were one continuous block of memory.

This mechanism is critical for EtherCAT’s high-speed “on-the-fly” data processing, enabling deterministic, low-latency fieldbus communication.

2. Why Does EtherCAT Need an FMMU?

Traditional fieldbus systems often require the master to communicate with each node separately, resulting in:

Higher latency

Increased communication overhead

Lower update rates

EtherCAT solves this with a different approach:

✔ The EtherCAT frame passes through all slaves in sequence.

Each slave reads and writes only the data that belongs to it.

✔ FMMU ensures the data is placed at the correct logical position.

The result is extremely efficient cyclic data exchange.

Key benefits enabled by FMMU:

Continuous logical address space for the Master

Precise byte-level mapping

Zero-copy, on-the-fly processing

Ultra-low cycle times (sub-100 μs)

High bandwidth utilization (close to 100%)

This is one of the main reasons EtherCAT is suitable for:

Motion control

Robotics

High-speed servo drives

Precision automation

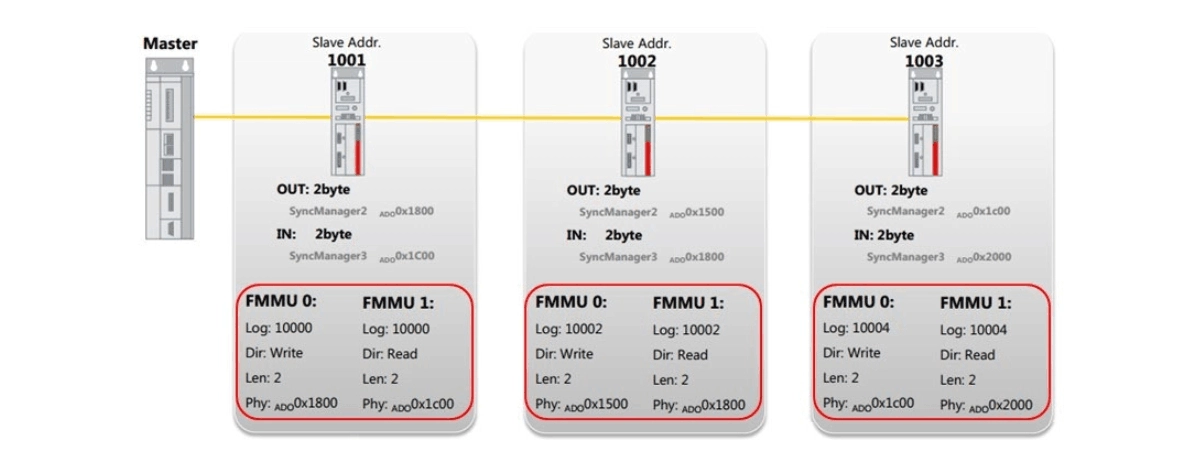

3. How FMMU Works: Logical vs. Physical Address Mapping

EtherCAT communication uses two types of memory addressing:

Logical Address (Master view)

A virtual, continuous address space defined by the Master for process data.

Physical Address (Slave view)

Actual register or data buffer addresses inside a slave device.

The FMMU maps logical memory → physical memory, enabling:

Bit-level granularity

Read/write control

Efficient synchronization with SyncManagers

Example:

If the Master creates a 60-byte logical PDO region:

Slave | Physical Memory | Mapped Logical Address |

|---|---|---|

Slave A | 0x1100 | 0x0000 – 0x000F |

Slave B | 0x2000 | 0x0010 – 0x0023 |

Slave C | 0x3200 | 0x0024 – 0x003B |

The Master only reads/writes one continuous 60-byte area, but data is automatically routed to each slave via their FMMU hardware.

4. FMMU Inside the EtherCAT Slave Controller (ESC)

The FMMU is implemented in the ESC (EtherCAT Slave Controller), which is integrated in EtherCAT slave chips such as:

Beckhoff ET1100

ET1200

Third-party ESC IP cores

Typical ESC includes:

FMMUs (usually 1–3 instances)

SyncManagers (SM)

AL state machine

Mailbox handlers

The FMMU configuration is performed during initialization via mailbox protocols (CoE, FoE, EoE).

5. FMMU and On-the-Fly Processing

One of EtherCAT's hallmark features is that slaves do not copy or buffer the entire Ethernet frame.

Instead:

The Ethernet frame streams through the slave.

The FMMU checks which bytes belong to this slave.

Data is inserted or extracted on the fly.

The frame continues to the next slave with a delay of nanoseconds.

This design enables update rates in the range of:

< 100 μs for 100+ axes servo control

< 10 μs per slave forwarding delay

No other fieldbus architecture achieves this level of determinism with such simple wiring.

6. Applications Where FMMU Is Critical

FMMU contributes directly to EtherCAT’s performance in:

Multi-axis motion controllers

Pick-and-place robots

CNC machines

Packaging and printing equipment

Semiconductor manufacturing

Real-time distributed I/O

Where the control cycle is extremely tight, the FMMU ensures stable and accurate data consistency.

LINK-PP Industrial Fiber Products for EtherCAT Networks

EtherCAT commonly uses Ethernet physical layers such as:

100BASE-TX

100BASE-FX

1000BASE-X

For environments requiring long-distance or EMI-resistant communications, LINK-PP provides a wide range of industrial-grade fiber transceivers and SFP modules:

Benefits for EtherCAT applications:

High EMC immunity

-40°C to +85°C industrial temperature options

Low latency and stable optical performance

Compatibility with PLCs, servo drives, and industrial switches

Long-distance links up to 80 km

These optical modules ensure reliable physical-layer connectivity for EtherCAT networks that rely on FMMU-based deterministic control.

7. Summary

The FMMU (Fieldbus Memory Management Unit) is one of the fundamental innovations that makes EtherCAT one of the fastest and most deterministic industrial networks. By mapping logical process data into slave-specific physical addresses and supporting on-the-fly frame processing, the FMMU enables:

Microsecond-level cycle times

Highly accurate synchronization

Efficient bandwidth use

Scalable distributed control

When paired with robust industrial optical modules, such as LINK-PP’s SFP and fiber transceivers, EtherCAT becomes a powerful and reliable backbone for modern automation systems.