📌 What Is MTBF?

MTBF (Mean Time Between Failures) is a critical metric in industrial engineering, reliability management, and network operations. It measures the average operational time a system or component runs before experiencing a failure.

MTBF is commonly used to:

Assess component reliability and durability

Plan preventive maintenance schedules

Predict system availability and downtime

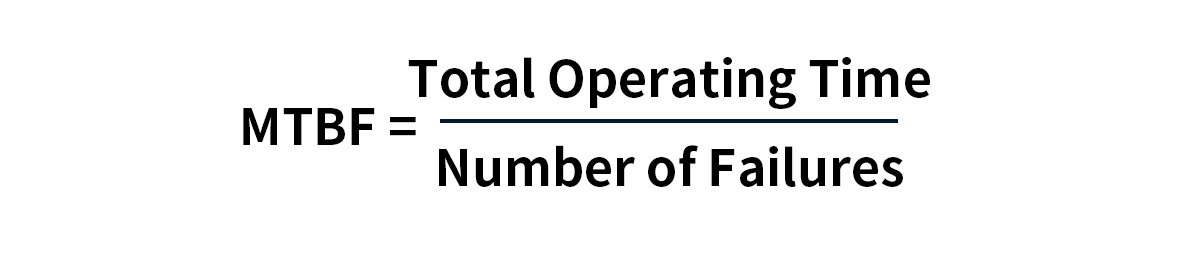

Formula for MTBF:

A higher MTBF indicates more reliable equipment and longer intervals between failures, which directly impacts operational efficiency and cost management.

📌 Why MTBF Matters

1. Enhancing System Availability

MTBF is directly linked to system uptime. Systems with higher MTBF require less frequent maintenance, minimizing interruptions and maximizing production or network availability.

2. Reducing Maintenance Costs

Frequent failures increase repair labor, parts costs, and downtime losses. Monitoring MTBF helps organizations identify weak points in design or operation, allowing targeted improvements that lower total maintenance costs.

3. Supporting Predictive Maintenance

Combining MTBF with real-time monitoring or IIoT data allows companies to implement predictive maintenance, preventing failures before they occur and optimizing operational schedules.

📌 How LINK‑PP Products Contribute to High MTBF

High MTBF is influenced by the reliability of the physical components used in industrial networks. LINK‑PP’s industrial-grade products are engineered to enhance system durability and reduce failure rates.

● SFP / SFP+ Optical Transceivers

LINK‑PP hot-swappable optical modules operate reliably in extended temperature ranges and harsh environments. Their robust design minimizes failures in fiber network links, contributing to longer MTBF.

● Industrial RJ45 Integrated Connectors

LINK‑PP RJ45 connectors feature reinforced housings, magnetic protection, and EMI suppression, ensuring stable signal transmission. This reduces intermittent faults and extends the average operational life of connected systems.

● LAN Magnetics and Transformers

Discrete magnetics and integrated transformer modules maintain signal integrity and reduce electrical stress on connected devices, preventing premature failures and increasing MTBF.

● Standards Compliance and Consistency

All LINK‑PP components follow IEEE, MSA, and industrial specifications, ensuring predictable electrical performance and mechanical reliability across deployments, further improving MTBF.

📌 Calculating MTBF in Industrial Systems

Record total operational time for each device or system.

Track the number of failures that occur within that period.

Divide total operating time by the number of failures:

MTBF=Total Operating HoursFailure Count\text{MTBF} = \frac{\text{Total Operating Hours}}{\text{Failure Count}}MTBF=Failure CountTotal Operating Hours

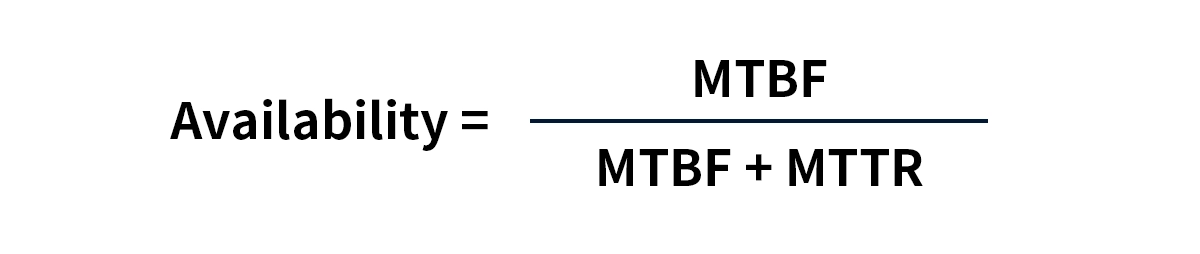

For example, if an industrial switch runs 10,000 hours and fails twice, MTBF = 5,000 hours. Combining MTBF with MTTR (Mean Time to Repair) allows engineers to calculate system availability:

📌 Best Practices to Maximize MTBF

Select industrial-grade components: Use high-reliability connectors and transceivers from trusted suppliers like LINK‑PP.

Implement preventive and predictive maintenance: Monitor performance and replace parts before failures occur.

Ensure environmental compliance: Components rated for vibration, temperature extremes, and EMI conditions reduce failure risks.

Maintain standardized installation and testing procedures: Proper installation avoids mechanical or electrical stress that could reduce MTBF.

📌 Conclusion

MTBF (Mean Time Between Failures) is essential for evaluating equipment reliability and planning maintenance in industrial networks and IIoT systems. Using high-quality, industrial-grade components—such as LINK‑PP SFP/SFP+ optical modules, RJ45 connectors, and LAN magnetics—can significantly increase MTBF, reduce downtime, and improve operational efficiency.

By integrating reliable hardware and adhering to best practices, engineers can design networks that are both long-lasting and highly available, ensuring consistent performance for critical industrial operations.