➡️ What Is MTTR?

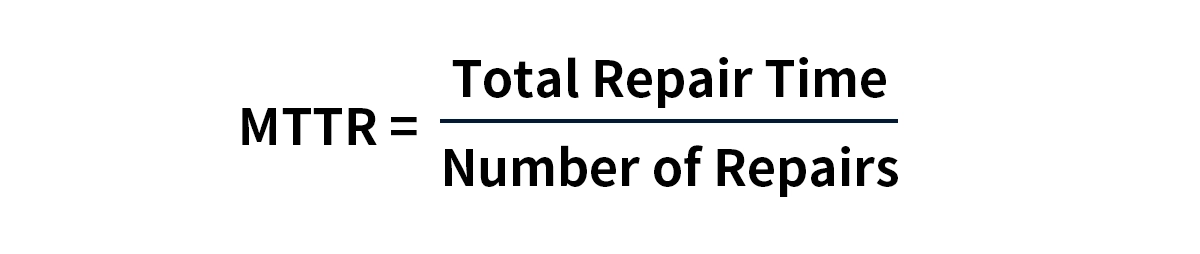

MTTR (Mean Time to Repair) is a key metric in reliability engineering and maintenance strategy. It measures the average time required to repair a system or component after a failure. MTTR is calculated by dividing the total repair time by the number of repair events over a given period.

MTTR typically refers to the active repair time, from the start of maintenance until the system is fully operational. In some cases, it is used interchangeably with Mean Time to Recovery, which can include detection and administrative delays.

➡️ Why MTTR Matters

1. Impact on Availability and Reliability

MTTR directly affects operational availability. A lower MTTR increases uptime, allowing organizations to meet production and service-level targets. Combined with MTBF (Mean Time Between Failures), it provides a comprehensive view of system reliability.

2. Cost and Risk Considerations

Long repair times increase labor, parts, and operational costs. Tracking MTTR identifies inefficiencies and highlights opportunities for process improvement, helping organizations reduce downtime-related expenses.

3. Supporting Maintenance Strategies

Accurate MTTR measurement informs predictive and preventive maintenance planning, spare parts inventory management, and realistic SLA definitions.

➡️ Common Challenges in MTTR Measurement

Skewed data: Outliers can distort average repair times.

Inconsistent definitions: Start and end points of repair vary across teams.

Excluded logistics: Supply chain or parts delays may not be counted, hiding true recovery time.

Process immaturity: Lack of standardized procedures can increase variability in MTTR.

➡️ Strategies to Reduce MTTR

▷ Standardize Repair Procedures

Use step-by-step protocols to ensure efficient, repeatable repairs.

▷ Maintain Spare Parts Inventory

Pre-staging essential components reduces delays in repairs.

▷ Leverage Hot-Swappable Hardware

Components that can be replaced without powering down systems significantly shorten MTTR.

▷ Use Diagnostic and Monitoring Tools

Real-time monitoring and remote diagnostics enable faster fault detection and resolution.

▷ Continuous Improvement

Root cause analysis after failures helps reduce future repair times.

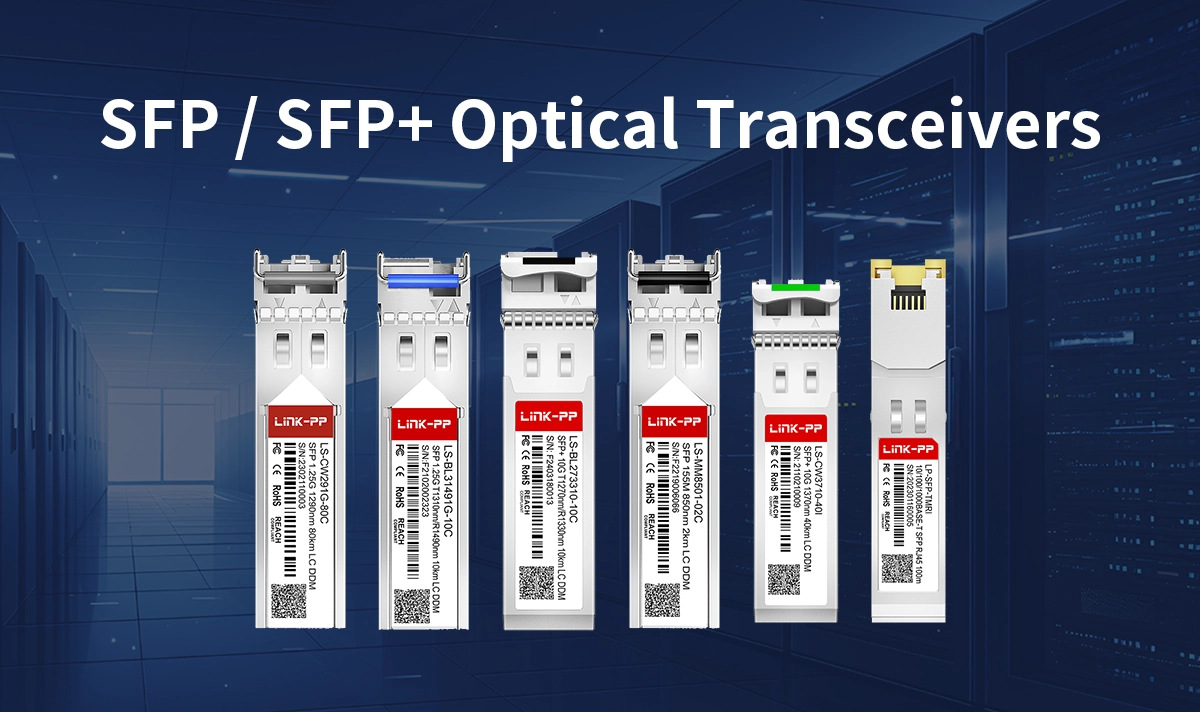

➡️ MTTR and LINK‑PP SFP / SFP+ Optical Transceivers

LINK‑PP hot-swappable SFP and SFP+ transceivers are designed to reduce MTTR in network environments:

Hot-Pluggable Modules: Replace failed transceivers without shutting down the system, minimizing downtime.

Reliable Performance: Consistent signal quality and adherence to MSA standards simplify troubleshooting.

Industrial Suitability: Modules designed for industrial temperature ranges and harsh environments ensure long-term reliability.

By integrating these components into industrial or data center networks, operators can significantly improve repair efficiency and system availability.

➡️ Best Practices for MTTR Optimization

Define MTTR consistently within your organization.

Track repair events with maintenance software or CMMS tools.

Use hot-swappable components like LINK‑PP SFP/SFP+ transceivers.

Keep spare transceivers readily available for rapid replacement.

Analyze MTTR trends to identify process improvements.

➡️ Conclusion

MTTR is a critical KPI for assessing and improving system reliability. Lowering MTTR enhances uptime, reduces maintenance costs, and strengthens operational resilience. Combining accurate measurement, efficient processes, and hot-swappable components such as LINK‑PP SFP/SFP+ optical modules provides a practical path to faster repairs and more reliable industrial networks.