▶ Introduction

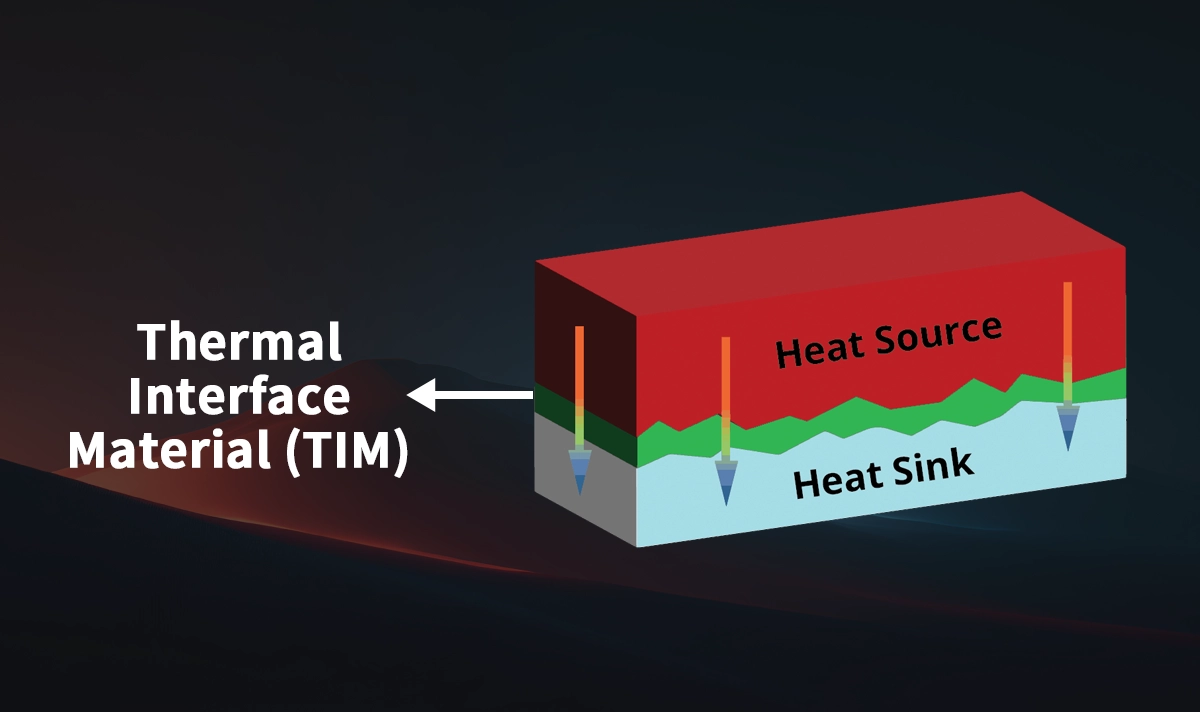

Thermal Interface Material (TIM) refers to substances placed between two solid surfaces—commonly a heat-generating chip and a heat sink—to enhance thermal conduction across microscopic air gaps. By replacing air (which has very low thermal conductivity, ~0.022 W/m·K) with a better-conducting medium, TIM significantly reduces thermal resistance and ensures steady heat flow. This improves device stability, performance, and lifespan.

▶ What Is TIM and Why Does It Matter

Electronic components, including CPUs, GPUs, power modules, and optical transceivers, generate heat during operation. Without effective heat transfer, localized temperatures can escalate, leading to reduced performance or even failure. TIM serves a critical function in the thermal management chain by filling surface irregularities and ensuring efficient heat transfer between components and heat-dissipating hardware.

▶ Common Types of TIM

Below are widely used TIM categories, each with distinct advantages and trade-offs:

Thermal Paste (Thermal Grease)

A viscous, non-curing compound that creates fragile bond lines and offers excellent thermal conductivity. Lacks mechanical strength, so always requires a fastening mechanism. Ideal for flat, high-contact interfaces.Thermal Adhesive

Similar to paste, but adds bonding strength once cured. Useful when both thermal conduction and mechanical adhesion are required.Thermally Conductive (Gap-Filler) Pads

Pre-formed, soft, solid pads made of silicone or paraffin-based materials. Easy to apply, suitable for non-flat surfaces. However, thermal performance is generally lower than paste.Thermal Tapes

Adhesive-backed, flexible, non-curing materials. Convenient and easy to use, with moderate thermal performance.Phase-Change Materials (PCMs)

Solid at low temperature, they soften or melt near 55–60 °C to fill gaps and enhance thermal conduction. Reusable and user-friendly.Metal TIMs (e.g., liquid metal, indium alloys, sintered silver)

Offering the highest thermal conductivities, these TIMs minimize interface resistance but require careful handling and may pose corrosion risks.

Thermal Conductivity Range

Typical composite polymer-based TIMs with particulate fillers can reach ~7 W/m·K. Thermal performance varies widely depending on formulation, ranging from ~0.3 W/m·K to tens or even hundreds of W/m·K for advanced or metal-based materials.

▶ How to Choose the Right TIM

Selection often depends on three core considerations:

Interface Gap: Minimal gaps (< 0.05 mm) suit paste or PCM; thicker gaps call for pads or gap fillers.

Contact Pressure: Some TIMs (e.g., paste) require sufficient mechanical pressure; pads and tapes may work under lower pressure.

Electrical Insulation: In sensitive electronics—including optical transceivers—TI M must not conduct electricity unless designed to. Many silicone-based pads or polymer TIMs are dielectric.

▶ TIM Relevance to LINK-PP Optical Transceiver Modules

LINK-PP’s range of optical transceivers—such as SFP, SFP+, QSFP+ modules operating at data rates from 1G to 100G—can generate thermal load under continuous transmission scenarios. Efficient thermal management ensures components like lasers, PIN diodes, and MCUs remain within safe operating temperature ranges for long-term reliability.

Applying a high-quality TIM (e.g., a thin thermal paste or soft pad) between a transceiver’s internal components and an external heat spreader or host housing can maintain optimal temperature, enhance device stability, and reduce failure rates—especially in compact or high-density deployments.

▶ Summary Table

Aspect | Description |

|---|---|

Definition | Material placed between the heat source and the sink to improve conduction |

Purpose | Replace low-conductivity air gaps, lower thermal resistance |

Common Types | Paste, adhesive, pads, tapes, PCMs, metal TIMs |

Key Selection Factors | Interface gap, pressure, and electrical insulation |

Importance of LINK-PP | Enhances the reliability and performance of optical transceivers |