The insatiable global demand for data is pushing network infrastructure to its limits. From cloud computing to AI and 5G, the backbone of our digital world relies on one critical element: speed. For decades, pluggable optical transceivers have been the workhorses of data centers. But as we race toward 800G and beyond, a new paradigm is emerging—On-Board Optics (OBO). This technology isn't just an incremental upgrade; it's a fundamental shift in how we design networks for greater density and efficiency. In this article, we'll unpack what OBO is, why it matters, and how it's setting a new standard for high-speed data transmission.

📝 Key Takeaways

On-Board Optics sends data with light signals. This makes data move faster and saves power. Devices work better because of this.

Optical transceivers change electrical signals into light signals. This helps circuit boards work faster and better.

Good planning is very important for On-Board Optics. It helps use space, cooling, and power in the best way.

On-Board Optics gives more bandwidth and channel density. This means more data connections fit in small spaces.

Optical parts need regular care to work well. This stops problems and keeps data safe.

📝 What Exactly Are On-Board Optics (OBO)?

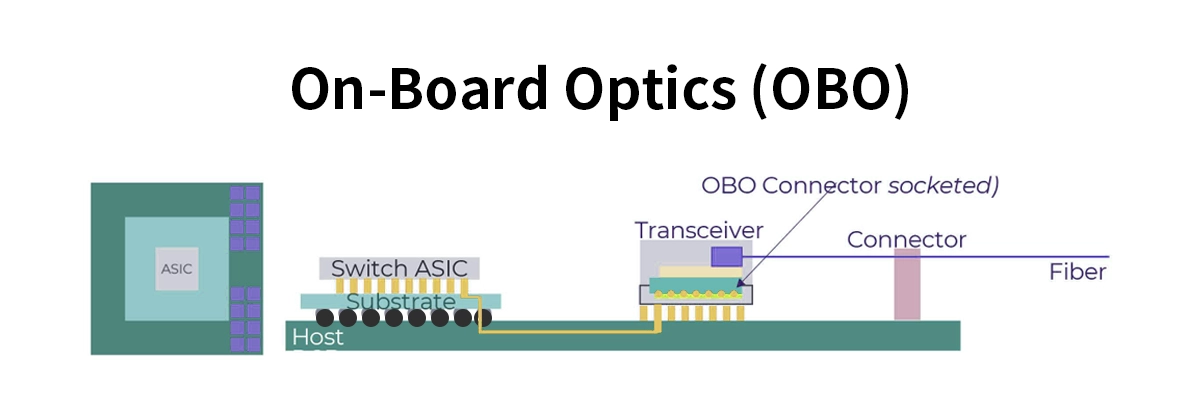

At its core, On-Board Optics refers to the integration of the optical engine directly onto the switch motherboard or a separate, attached PCB (Printed Circuit Board). Unlike traditional pluggable modules (like QSFP-DD or SFP+) that slot into faceplate ports, OBO moves the optics inside the equipment.

The fundamental principle involves shortening the electrical signal path. In a pluggable setup, a high-speed electrical signal travels from the switch ASIC (Application-Specific Integrated Circuit) to the faceplate, through a connector, and into the pluggable module, where it's converted to light. This electrical pathway is lossy and power-hungry at higher speeds. OBO eliminates most of this path by placing the laser and photodetectors much closer to the switch ASIC, converting the signal to light right on the board. The light is then routed out of the system via fiber optic cables connected to optical connectors on the chassis.

This architecture is a cornerstone for developing scalable and power-efficient data center architectures, addressing the critical pain points of modern hyperscale operators.

📝 The Compelling Advantages of On-Board Optics

The move to OBO is driven by several key benefits that directly address the limitations of pluggable transceivers.

Enhanced Power Efficiency: By drastically reducing the length of the high-speed electrical trace, OBO minimizes signal loss and the need for powerful DSP (Digital Signal Processing) chips. This translates to significantly lower power consumption per bit—a critical metric for operators with massive energy costs.

Increased Port Density and Form Factor Optimization: Removing bulky pluggable cages from the faceplate frees up valuable real estate. This allows switch manufacturers to pack more ports into a single unit or design more compact and streamlined systems, enabling higher-density network switch designs.

Reduced Total Cost of Ownership (TCO): While the initial hardware cost might be comparable, the savings in operational expenses are substantial. Lower power consumption and reduced cooling requirements contribute to a significantly lower TCO over the system's lifetime.

Improved Signal Integrity: At data rates of 400G, 800G, and 1.6T, electrical signals over longer distances are prone to attenuation and crosstalk. OBO's short-reach electrical interfaces preserve signal integrity, enabling more robust and reliable performance.

📝 Navigating the Challenges and Considerations

While promising, the adoption of OBO is not without its hurdles. Understanding these key challenges in deploying on-board optics is crucial for network architects.

Upfront Design Complexity: Integrating optics directly onto the board requires co-design between switch vendors, optical component suppliers, and system integrators. This makes the initial design phase more complex and less flexible than using standardized pluggables.

Serviceability and Upgradeability: This is the most cited challenge. With pluggables, you can easily replace a faulty module or upgrade a link without touching the entire switch. With OBO, a failure in the optical component might require replacing the entire board, leading to potential downtime and higher repair costs.

Ecosystem and Standardization: The pluggable transceiver market is mature and highly standardized (via MSA groups). The OBO ecosystem is still evolving, with multiple form factors and interfaces competing for dominance.

📝 On-Board Optics in Action: Real-World Applications

OBO isn't a one-size-fits-all solution; it excels in specific, high-demand environments.

Hyperscale Data Centers: For giants like Google, Meta, and Amazon, where power, space, and cost are paramount, OBO is a game-changer for top-of-rack (ToR) and spine-leaf architecture interconnects.

Disaggregated Networks and White-Box Switches: OBO aligns perfectly with the philosophy of disaggregation, allowing for customized hardware optimized for specific workloads.

High-Performance Computing (HPC) and AI Clusters: AI training and scientific computing require massive, low-latency interconnects between thousands of GPUs. The density and efficiency of OBO make it ideal for these applications.

📝 A Closer Look at Optical Modules: The Heart of the System

To truly appreciate OBO, one must understand the optical module at its core. An optical transceiver is the device that converts electrical signals to optical signals and vice-versa. While pluggable modules are self-contained units, the core components—the laser drivers, TIAs (Transimpedance Amplifiers), and the optical engine (often based on COC, CPO, or silicon photonics)—are what get integrated in an OBO design.

Leading manufacturers are pioneering this space with robust and innovative solutions. For instance, LINK-PP, a specialist in advanced photonic solutions, offers a range of high-performance optical transceivers designed for both traditional and integrated applications. A prime example of their engineering excellence is the LINK-PP 400G-DR4 module.

This specific module is engineered for high-density 400G applications, featuring:

A compact form factor designed for direct board-mounting.

Support for 500m transmission over single-mode fiber.

Exceptionally low power consumption, aligning perfectly with the core advantages of the OBO architecture.

High reliability, which is critical when the optics are no longer easily field-replaceable.

Integrating a reliable module like the LINK-PP LQD-CW400-DR4C ensures that the entire OBO system delivers on its promise of performance and efficiency, making it a top choice for next-generation data center interconnects.

📝 On-Board Optics vs. Pluggable Optics: A Quick Comparison

The following table provides a clear, side-by-side comparison of these two technologies to help you understand their key differentiators.

Feature | On-Board Optics (OBO) | Pluggable Optics (e.g., QSFP-DD) |

|---|---|---|

Power Consumption | Lower (shorter electrical path) | Higher |

Port Density | Higher (no faceplate cages) | Lower |

Initial Flexibility | Lower (fixed configuration) | Higher (hot-swappable) |

Thermal Management | More complex (inside the chassis) | Simpler (at the faceplate) |

Total Cost of Ownership (TCO) | Potentially Lower (opex savings) | Higher (opex) |

Best For | Hyperscale, HPC, fixed-configuration | Enterprise, telecom, flexible networks |

📝 Conclusion: Embracing the Integrated Paradigm

On-Board Optics represents a pivotal shift in network design, moving us away from the convenience of pluggability toward the raw efficiency of integration. While challenges around serviceability remain, the benefits in power, density, and cost are too significant for hyperscale and HPC environments to ignore. As the technology matures and the ecosystem around vendors like LINK-PP grows, we can expect OBO to become a mainstream choice for building sustainable and high-bandwidth data centers. The future of connectivity isn't just faster; it's smarter, denser, and more integrated.

📝 FAQ

What is the main purpose of on-board optics?

You use on-board optics to move data faster and save energy. This technology brings light signals close to your chips. You get higher speeds and better power use in your devices.

How do on-board optics help data centers?

On-board optics let you fit more connections in less space. You can move more data between servers. Your data center uses less power and stays cooler.

Tip: On-board optics help you build greener and faster data centers.

Are on-board optics hard to install?

You need careful planning and clean tools. Some connectors are small and need steady hands. You can follow guides from groups like COBO to make setup easier.

What devices use on-board optics?

You find on-board optics in data centers, supercomputers, and advanced network gear. These devices need fast data and many connections.

Data centers

Supercomputers

Telecom equipment