In the relentless pursuit of higher bandwidth, lower latency, and greater efficiency, network architects face a critical decision at the heart of every data center and telecom infrastructure: how to integrate optical transceivers. For decades, the answer was simple: pluggable optics. But a formidable challenger has emerged: On-Board Optics (OBO).

This isn't just a minor technical choice; it's a strategic decision that impacts your network's power consumption, density, scalability, and total cost of ownership. In this deep dive, we'll unpack the key differences, advantages, and ideal use cases for each technology to help you navigate this crucial data center interconnect (DCI) landscape.

⚔️ Key Takeaways

Pluggable optics give you more choices. You can change modules to make your network better without buying new gear.

On-board optics work faster. They are inside the device, so data moves quicker and there is less delay.

Think about the price. Pluggable optics cost less at first, but on-board optics need more money to start.

Look at how much space you have. On-board optics use less room and let you connect more things in a small spot.

Think about upgrades later. Pluggable optics help you grow your network slowly, but on-board optics need more planning if you want to change things.

⚔️ Understanding the Core Concepts

What are Pluggable Optics?

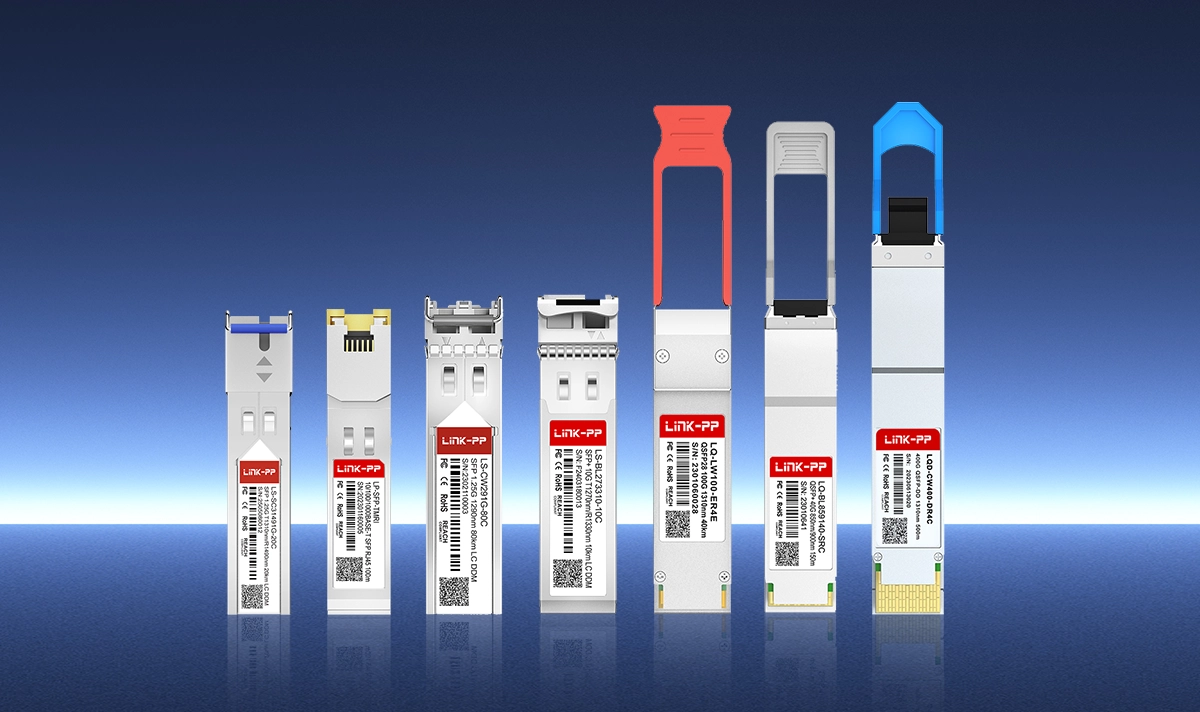

Pluggable optics are the familiar, modular transceivers you hot-swap into the front panel of switches, routers, and network interface cards. They are standardized (e.g., QSFP-DD, OSFP, SFP+) and form a critical electro-optical interface, converting electrical signals from the switch ASIC into optical signals for transmission over fiber.

Key Feature: Their modularity. If a transceiver fails or you need to upgrade a link, you simply unplug and replace it without taking the entire system down.

What are On-Board Optics (OBO)?

On-Board Optics flips this model on its head. Instead of a pluggable module, the optical engine is soldered directly onto the switch's main board—"on-board." The electrical interface to the switch's ASIC is much shorter, and the optical fiber is connected directly to a port on the line card.

Key Feature: Integration. By eliminating the pluggable cage and associated components, OBO aims for higher density and lower power consumption.

⚔️ The Great Debate: A Head-to-Head Comparison

Let's break down the performance of these two architectures across key parameters.

Feature | Pluggable Optics | On-Board Optics (OBO) | Winner for... |

|---|---|---|---|

Flexibility & Maintenance | ✅ High. Easy to upgrade, replace, and manage inventory. Mix and match vendors. | ❌ Low. Fixed configuration. A failure may require replacing the entire line card. | Pluggable Optics |

Power & Thermal Efficiency | ⚠️ Moderate. Higher power per bit due to longer, less efficient electrical path. | ✅ High. Shorter electrical path reduces power consumption and heat generation. | On-Board Optics |

Port Density | ⚠️ Moderate. Limited by physical size of modules and faceplate. | ✅ High. Eliminates cage, allowing for more ports in the same space. | On-Board Optics |

Signal Integrity | ❌ Challenging at >400G. Longer electrical traces can cause signal degradation. | ✅ Superior. Shorter path enables cleaner signals for 800G, 1.6T, and beyond. | On-Board Optics |

Total Cost of Ownership (TCO) | ✅ Lower Capex. Lower initial hardware cost; pay-as-you-grow. | ❌ Higher Capex. Higher initial switch cost. Potentially lower Opex (power/cooling). | Context-Dependent |

⚔️ The Crucial Role of Optical Transceivers

At the core of this discussion is the optical transceiver itself. It's the workhorse of modern networking, performing the essential conversion between the electronic world of silicon and the photonic world of fiber optics. Whether pluggable or on-board, its job remains the same: ensuring data is transmitted accurately over ever-increasing distances.

For network planners looking to future-proof their high-speed data center infrastructure, choosing the right transceiver technology is paramount. This is where the performance and reliability of components from manufacturers like LINK-PP become critical. Their expertise in both pluggable and co-packaged optics solutions provides valuable options for different architectural paths.

For instance, the LINK-PP QSFP-DD 400G DR4 module is a stellar example of a high-performance pluggable solution, enabling seamless migration to 400G networks with low power consumption and exceptional reliability—a key consideration for reducing operational expenses.

⚔️ Pluggable vs. On-Board: Which Solution is Right for Your Network?

The choice isn't about which technology is "better" in a vacuum, but which is better for your specific needs.

Choose Pluggable Optics if:

You value flexibility and modularity above all else.

Your network is multi-vendor, and you need the freedom to source components competitively.

Your upgrade cycle is gradual, and you prefer a "pay-as-you-grow" model.

Maintenance and quick swaps are a top priority for your operational workflow.

Choose On-Board Optics if:

You are building a hyperscale data center where power and cooling efficiency are the primary constraints.

You need maximum front-panel port density for top-of-rack (ToR) or spine-leaf architecture applications.

You are designing for the next generation of speeds (800G/1.6T+) where signal integrity is paramount.

You have a standardized, large-scale deployment where the initial Capex can be justified by significant Opex savings.

⚔️ The Future is Co-Packaged, But Pluggable is Here to Stay

The industry is already looking beyond OBO to the next frontier: Co-Packaged Optics (CPO), where the optical engine is placed inside the same package as the switch ASIC. This promises even greater power and density gains.

However, this does not spell the end for pluggable optics. The pluggage optics market remains robust and innovative, with new form factors like QSFP-DD and OSFP-XD pushing data rates to 800G and 1.6T per module. The flexibility and interoperability of pluggables are simply too valuable for a vast majority of enterprise and telecom networks.

For most, the future will be a hybrid one, leveraging the strengths of both technologies in different parts of the network.

⚔️ Conclusion: A Strategic Partnership with LINK-PP

The debate between pluggable and on-board optics underscores a healthy, evolving industry pushing the limits of physics and economics. There is no one-size-fits-all answer.

As you plan your network's evolution, partnering with a technology leader like LINK-PP is crucial. Whether you are deploying a flexible, high-performance network using their reliable LINK-PP QSFP-DD 400G DR4 modules or exploring the next-generation efficiencies of their OBO and CPO solutions, their expertise can guide you to the optimal optical networking strategy.

By carefully evaluating your requirements for power efficiency, thermal management, and port density, you can make an informed decision that ensures your infrastructure is not only powerful today but also ready for the challenges of tomorrow.

⚔️ FAQ

What is the main difference between pluggable optics and on-board optics?

Pluggable optics let you swap modules easily. On-board optics stay fixed on the device. You get more flexibility with pluggable optics. On-board optics give you higher integration and speed.

Which option is better for future upgrades?

You can upgrade pluggable optics by changing modules. This makes upgrades simple. On-board optics need more planning. You must replace the whole device for upgrades.

How do power and cooling needs compare?

On-board optics use less power and create less heat. Pluggable optics may need more energy as you add modules. You should check your data center’s power and cooling limits.

Can I mix pluggable and on-board optics in one network?

Yes, you can use both types together. Many data centers mix them to get the best of both. You use pluggable optics for flexibility. You use on-board optics for high density and speed.

Which is easier to maintain?

Pluggable optics are easier to maintain. You can swap modules without turning off your system. On-board optics need more time for repairs. You may need to stop the device for service.