Introduction

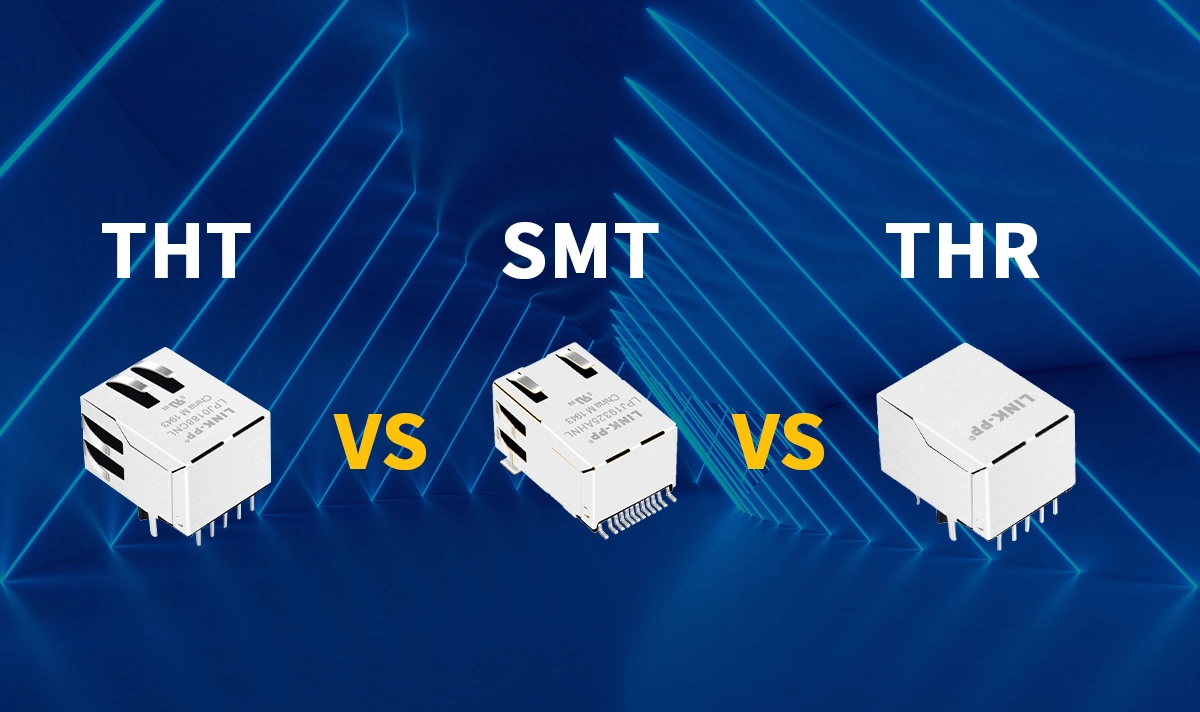

Selecting the right RJ45 connector mounting method is a critical decision in network hardware design. From industrial automation to consumer electronics, the way an RJ45 connector is attached to a PCB directly affects electrical performance, mechanical reliability, and manufacturing efficiency. The three most common approaches—Through-Hole Technology (THT), Surface-Mount Technology (SMT), and Through-Hole Reflow (THR)—each serve specific engineering goals. In this guide, we break down these methods in detail and introduce real-world examples from LINK-PP, a leading RJ45 connector manufacturer.

Quick Comparison

Feature | THT | SMT | THR |

|---|---|---|---|

PCB Hole Required | ✅ Yes | ❌ No | ✅ Yes |

Soldering Method | Wave Soldering | Reflow Soldering | Reflow Soldering |

Mechanical Strength | ⭐⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐⭐ |

Automation Compatibility | ⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ |

Space Efficiency | ⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ |

Best Use Case | Industrial/Heavy Duty | Compact Consumer Devices | Hybrid/Automated Industry |

Ethernet Speed Support | Up to 10Gbps+ | Up to 10Gbps | Up to 10Gbps+ |

Cost | Moderate | Low | Moderate |

Mounting Methods

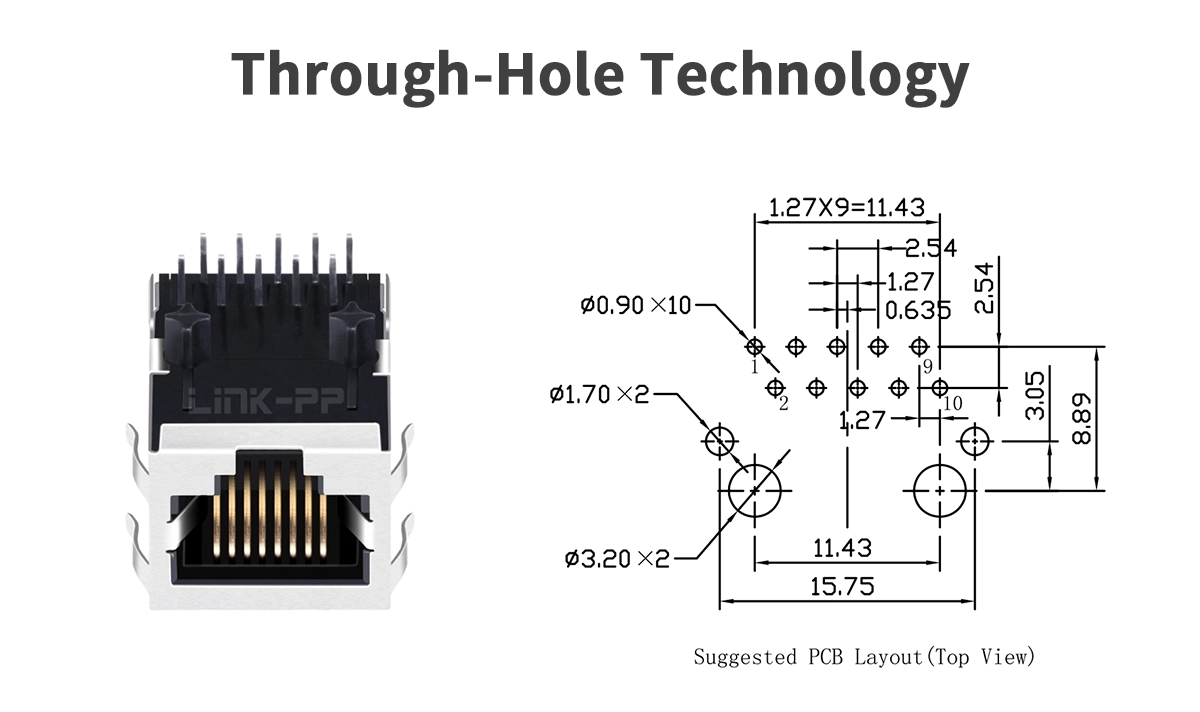

1. THT (Through-Hole Technology)

Overview

THT involves inserting connector pins into drilled holes on the PCB, with solder joints formed on the opposite side—typically using wave soldering. This traditional technique offers strong mechanical retention and has long been the standard in industrial and high-reliability environments.

Advantages

Superior mechanical strength for environments with vibration or stress

Ideal for heavier or magnetics-integrated RJ45 connectors

Proven long-term durability

Limitations

Requires drilling plated holes, increasing PCB manufacturing cost

Takes up more board space, limiting use in dense layouts

Common Applications

Industrial switches

Power over Ethernet (PoE) devices

Legacy routers and network hubs

LINK-PP THT RJ45 Examples

📌 Model: LPJ0188CNL

A shielded RJ45 connector with integrated magnetics, optimized for 10/100Base-T applications.

🔍 Download datasheet

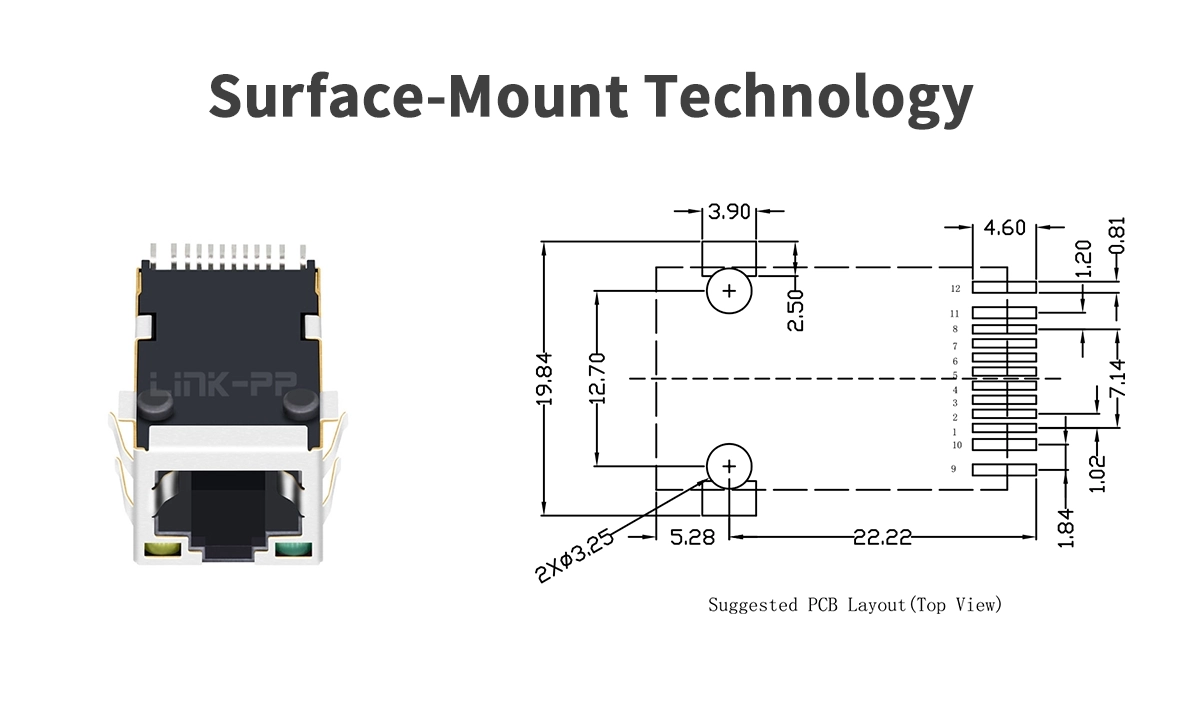

2. SMT (Surface-Mount Technology)

Overview

SMT RJ45 connectors are soldered directly onto the surface of the PCB using reflow soldering, eliminating the need for hole drilling. This makes them ideal for automated production and compact electronic designs.

Advantages

Space-saving for high-density layouts

Lower cost due to reduced PCB drilling

High-speed automated assembly compatible

Limitations

Weaker mechanical stability under physical stress

Less suited for environments requiring frequent plugging/unplugging

Common Applications

Home routers and set-top boxes

Embedded Ethernet modules

Compact consumer devices

LINK-PP SMT RJ45 Example

📌 Model: LPJ19325AHNL

A compact Surface-Mount RJ45 Jacks, designed for Digital Camera and Router.

🔍 Download datasheet

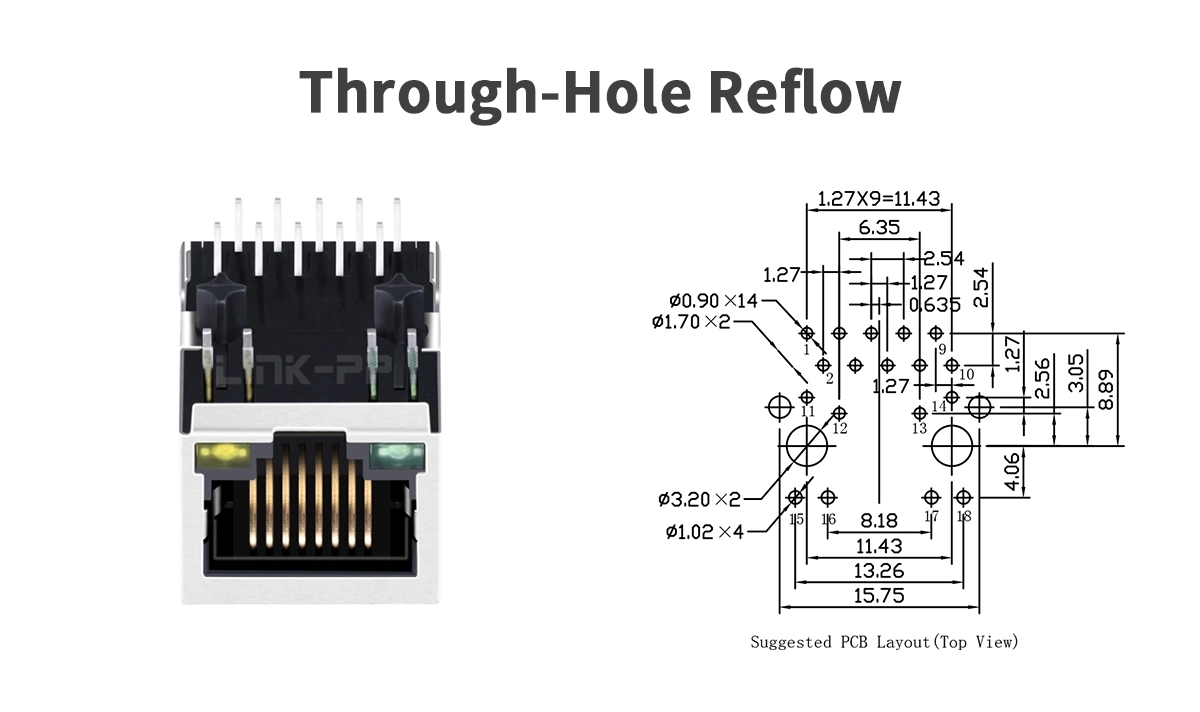

3. THR (Through-Hole Reflow)

Overview

THR combines the mechanical benefits of THT with the automation compatibility of SMT. The connector’s leads pass through holes in the PCB and are soldered via reflow, not wave soldering. This hybrid approach simplifies production without sacrificing strength.

Advantages

High mechanical strength similar to THT

Streamlined with SMT reflow processes

Compatible with double-sided reflow assembly

Limitations

Requires heat-resistant materials

Slightly more complex PCB pad and stencil design

Common Applications

Automotive Ethernet systems

High-reliability embedded systems

Industrial IoT devices

LINK-PP THR RJ45 Example

📌 Model: LPJG0926HENLS4R

An advanced THR RJ45 with integrated magnetics, shielded body, and enhanced EMI protection—ideal for PoE+ and gigabit Ethernet systems.

🔍 Download datasheet

📘 How to Choose the Right Mounting Method for RJ45 Connectors

Selecting the best mounting style isn’t just about preference — it depends on the application’s mechanical, electrical, and manufacturing requirements. Below are some practical guidelines:

★ Prioritize Mechanical Strength?

Use THT for robust industrial deployments, especially in environments prone to vibration or mechanical stress.

★ Need Compact, High-Density PCB Layout?

Go with SMT RJ45 connectors. They are surface-mountable and compatible with automated reflow soldering processes.

★ Looking for Reflow Compatibility + Mechanical Strength?

THR offers the best of both worlds. It enables reflow soldering while maintaining the mechanical stability of through-hole components — LPJG0926HENLS4R is a reliable option.

★ Design for Automated Assembly?

Both SMT and THR connectors are compatible with automated pick-and-place and reflow lines, reducing labor cost and improving consistency.

★ Cost vs. Reliability Trade-Off?

THT may increase cost due to drilling but enhances durability.

SMT is cost-effective for large-scale, compact designs.

THR balances both, especially where wave soldering is not feasible.

🔎 Also See

Enhance your understanding of PCB mounting and soldering technologies with these related resources from LINK-PP:

What is THT (Through-Hole Technology)?

Understand the fundamentals of traditional THT and its role in PCB assembly.What Does SMT (Surface Mount Technology) Mean?

Learn how SMT revolutionized automated electronics production.Through-Hole Reflow (THR) Soldering Process Explained

A deeper look into how THR works and why it matters in modern assembly lines.Wave Soldering vs Reflow Soldering: Key Differences & Applications

Compare the two dominant soldering methods and discover their ideal use cases.