In modern industrial automation, the link between programmable logic controllers (PLCs) and supervisory control and data acquisition (SCADA) hosts hinges upon reliable Ethernet connectivity. At the heart of that connectivity lies the RJ45 Magjack—an Ethernet connector that integrates magnetics and shielding to ensure signal integrity, noise immunity, and system robustness. This article reviews the key role of Magjack connectors in the PLC-to-SCADA communication path, dissects their technical features, and explains how they contribute to industrial Ethernet reliability.

🔁 Why the Connection Between PLC and SCADA Host Matters

In a typical automation architecture, a PLC (or remote terminal unit, RTU) aggregates field-device data and exchanges it with the SCADA host for monitoring, control, and analytics. For example, sensors relay measurements to the PLC, the PLC sends data and receives control commands via Ethernet to the SCADA server or master station. Within this chain, the Ethernet interface must provide:

High-speed, low-latency data transfer so that SCADA operators have real-time visibility and control.

Robust physical and signal integrity in harsh industrial environments (electromagnetic interference (EMI), ground potentials, vibration, temperature extremes).

Galvanic isolation and protection from transient surges or ground loops between distributed devices.

Space-efficient board layout to fit compact PLC modules and control network cards.

Because that interface often uses an RJ45 connector mounted on the PCB, choosing the right connector becomes critical to the overall system reliability.

🔁 What Is an RJ45 Magjack?

An RJ45 Magjack is a modular Ethernet jack (8P8C) with integrated magnetics (isolation transformers, common-mode chokes, sometimes status LEDs, and shielded housing) built into the connector module itself.

Key advantages include:

Signal conditioning and isolation: The built-in magnetics (transformer + chokes) help suppress noise, reduce reflections and crosstalk, and provide galvanic isolation (typically 1.5 kVrms or higher) between the device and network.

EMI/EMC performance: Shielded housing plus internal magnetics deliver better immunity in industrial environments with high electrical noise (motors, drives, switching power supplies).

Board-space efficiency and simplified design: Because discrete magnetic components are already embedded inside the Magjack, PCB layout becomes simpler and smaller, important for PLC modules and compact network cards.

Versatility for industrial Ethernet: Many Magjacks support 10/100 Base-T and 1 Gigabit Ethernet, PoE/PoE+ compatibility, and industrial-grade mounting.

Thus, for linking a PLC to a SCADA host over Ethernet, the Magjack ensures that the physical layer does not become a weak link.

🔁 How Magjacks Serve the PLC ↔ SCADA Path

1. Physical Interface on the PLC Side

On the PLC module or embedded automation controller, the Integrated RJ45 Connector provides the Ethernet port that connects to network switches or directly to SCADA server hubs. At this stage, the Magjack ensures that the PLC’s Ethernet PHY sees a clean, isolated interface, immune to ground-loop differentials or large EMI impulses from the factory floor.

2. Network Connectivity & Transmission Integrity

Between the PLC and SCADA host, Ethernet cables (Cat5e/Cat6), switches, or industrial Ethernet switches transmit data frames. A Magjack’s built-in magnetics and shielding help maintain signal integrity across these cables and through electromagnetic harsh zones. This reduces packet loss, minimizes retries, and keeps deterministic communication stable—critical for SCADA control loops.

3. Host/SCADA Side and Full-System Reliability

On the SCADA host or master station side, the RJ45 Magjack again serves as the physical link. Any degradation in the interface (poor isolation, EMI susceptibility) may cause data omissions, erroneous alarms, or control delays. By using Magjacks, system designers bolster the reliability of the entire PLC ↔ SCADA architecture.

4. Industrial Automation Demands

In industrial automation settings (e.g., manufacturing plants, power substations, water treatment plants), the Ethernet interface must survive mechanical stress, dust, vibration, high humidity, and frequent cable changes. Magjack modules designed for through-hole mounting, strong mechanical retention, and LED-based diagnostics help meet these demands.

🔁 Key Selection Criteria for RJ45 Magjacks in PLC/SCADA Systems

When specifying a Magjack for a PLC-to-SCADA link, consider the following attributes:

Ethernet speed and standard: Ensure support for required data rates (10/100 Mb/s or 5 Gb/s) and auto-MDIX capability.

Integrated magnetics: Transformers and chokes should be built in, rated for isolation (e.g., 1500 Vrms), minimizing external components.

EMI/EMC rating, shielded housing: For industrial environments, look for certification or tests like IEC61000-4-2/−4-3, etc.

Mechanical mounting: Through-hole versions offer better vibration/resilience than surface-mount for PLC boards in harsh environments.

PoE/PoE+ compatibility: If the PLC or edge node requires power via Ethernet, ensure the Magjack supports IEEE 802.3af/at/bt.

Diagnostics (LEDs): Link/activity LEDs provide quick field diagnostics—valuable for SCADA network maintenance.

Vendor ecosystem & lifecycle: For industrial automation, choose connectors from reliable vendors with long product-life support.

🔁 Tips for Integration in PLC–SCADA Ethernet Interfaces

Segregate Ethernet network traffic: For SCADA links, keep control traffic separate from office traffic; use VLANs or physically separate switches to reduce latency and avoid interference.

Cable routing and grounding: Avoid running Ethernet cables parallel to high-voltage or high-current lines. Use shielded cables and bonding of chassis ground to minimize ground loops.

Use industrial-rated Magjacks: Select Magjack connectors designed for industrial grade (temperature, vibration, board retention) to avoid failure in harsh environments.

Regular diagnostics & monitoring: Use link/activity LEDs and network monitoring to detect degraded physical layers (increased packet retry, link drops) before they impact SCADA performance.

Redundancy and fail-safe design: In critical PLC↔SCADA links, consider redundant network paths or dual Magjack ports to ensure continuity in case of connector or cable failure.

Proactive maintenance: Replace aged connectors, inspect cable terminations, and check for signs of corrosion or mechanical looseness—this attention to the physical layer enhances the overall SCADA system’s reliability.

🔁 How LINK-PP Supports Reliable PLC ↔ SCADA Ethernet Interfaces

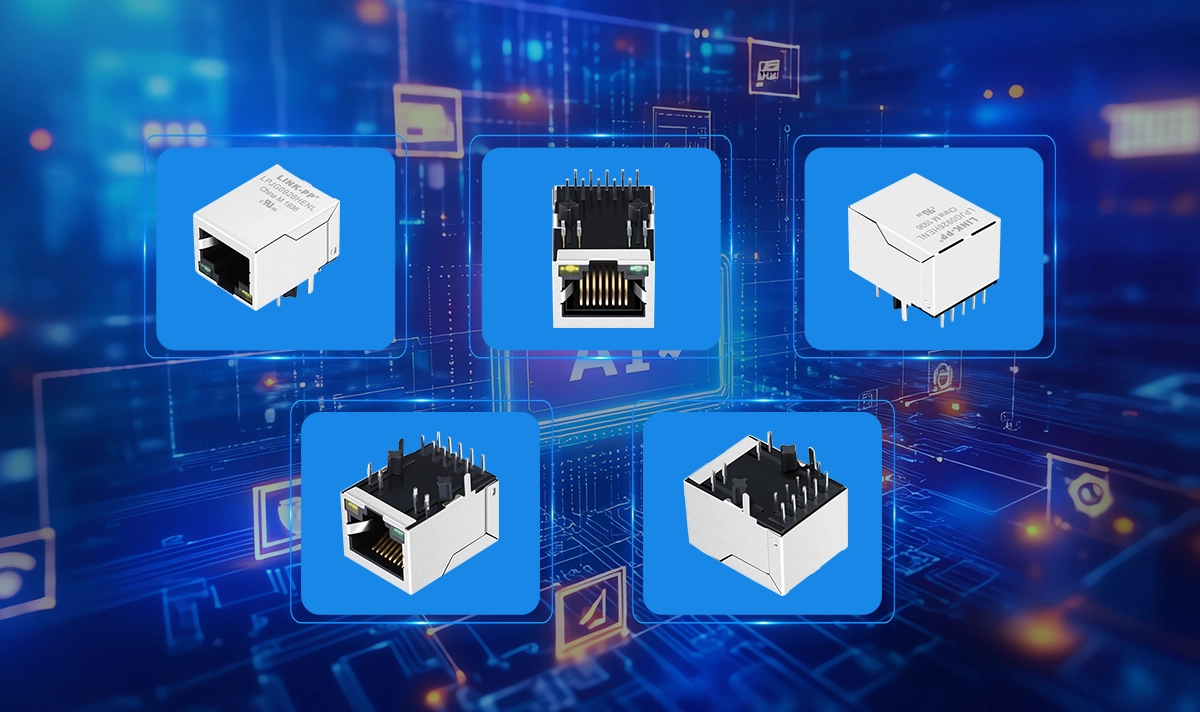

At LINK-PP, we provide a broad portfolio of high-performance RJ45 Magjacks tailored for industrial automation, including models with integrated magnetics, PoE/PoE+ support, strong mechanical retention, and industrial temperature ratings. For example, the LPJG0926HENL is specifically highlighted for its suitability in industrial automation and IoT gateway applications.

By selecting the right Magjack from LINK-PP, system designers can ensure that their PLC-to-SCADA communication path remains robust, interference-resilient, and future-proof—supporting the long lifecycles typical in automation systems.

🔁 Conclusion

In summary, while the software and protocols of PLC ↔ SCADA communication often receive much attention, the physical interface is equally critical. The RJ45 Magjack plays a foundational role by providing an Ethernet interface that ensures signal integrity, isolation, and resilience in challenging industrial environments. When properly selected and integrated, Magjacks contribute directly to the reliability, uptime, and performance of SCADA systems and automation networks.

For designers and engineers working in industrial automation, specifying the right Magjack is not just a component choice—it’s a strategic decision that impacts long-term operational success. With LINK-PP’s industrial-grade Magjacks, you can build smarter, more connected, and more reliable PLC-to-SCADA Ethernet links.