In today’s industrial automation landscape, the distributed control system (DCS) is a foundational architecture that ensures reliable, scalable, and real-time process control. This article explains DCS architecture, applications, benefits, and modern trends, highlighting how LINK‑PP connectivity solutions support DCS implementations.

⚙️ What is a Distributed Control System (DCS)?

Definition and Core Concept

A distributed control system (DCS) is a computerized automation system designed to control industrial processes with multiple control loops through decentralized controllers. Unlike a single central controller, a DCS distributes control nodes across the plant, improving reliability and real-time responsiveness.

Why “Distributed”?

Control functions are spread across multiple nodes near field devices (sensors and actuators). This decentralisation reduces single-point failures and ensures faster local responses, making DCS ideal for large-scale, continuous, or batch process industries.

⚙️Key Components and Architecture of a DCS

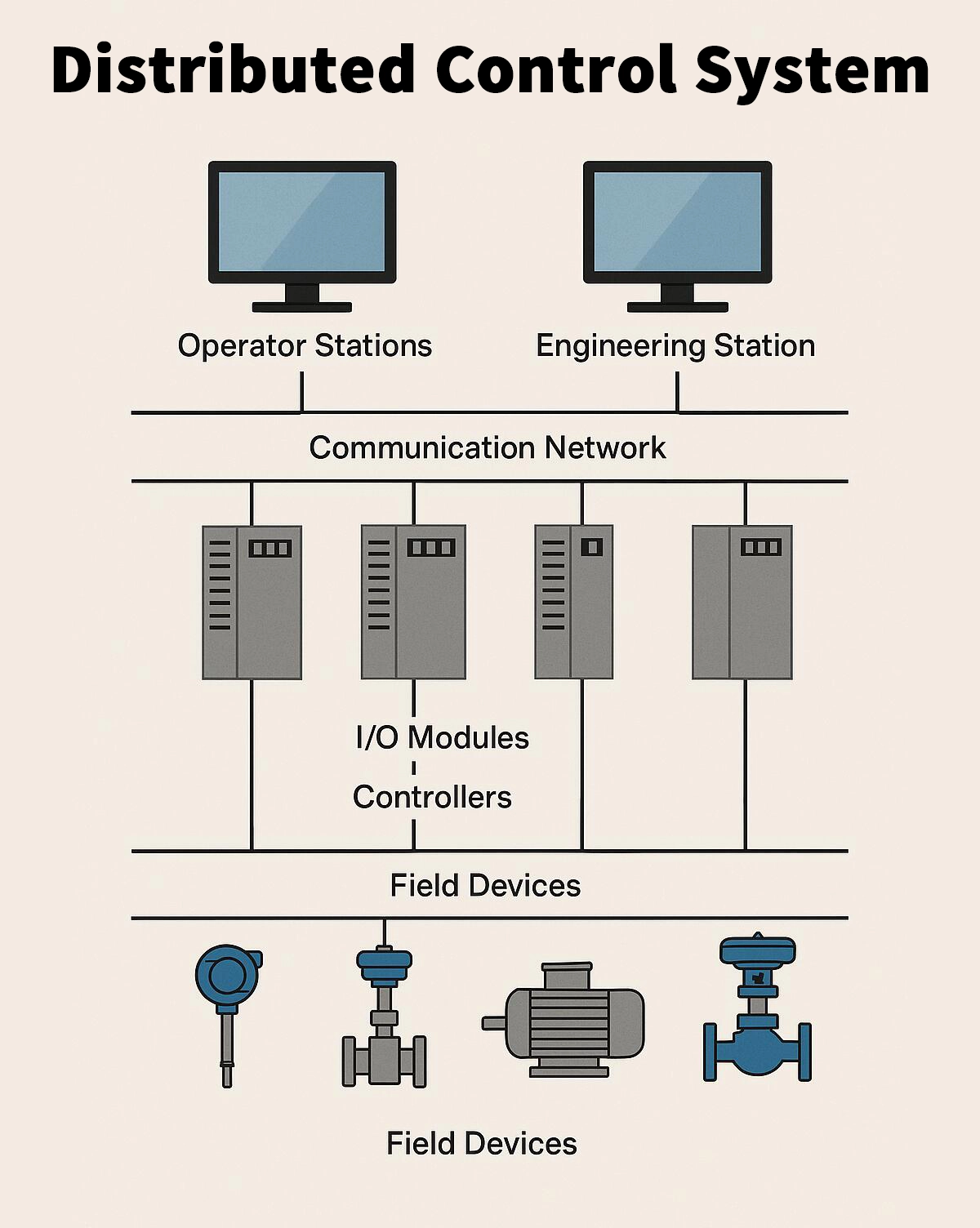

Typical Layers

Field devices (Level 0): Sensors, transmitters, and actuators that measure and act on process variables.

I/O modules and local controllers (Level 1): Execute control logic and interface with field devices.

Supervisory computers/operator stations (Level 2): Provide Human-Machine Interface (HMI) for monitoring, alarms, and manual intervention.

Engineering station & historian: For configuration, programming, data logging, and analytics.

Communication network: High-speed, redundant plant networks (Ethernet, Profibus, Modbus) linking all layers.

Functional Modules

Control nodes/controllers: PID loops, logic execution, alarm handling.

HMI/operator interface: Visualisation and operator controls.

Alarming and event management: Alerting for threshold breaches.

Data logging/historian: Historical process data for analysis.

Engineering environment: Configuration, updates, and optimisation.

Modern Integration

DCS now integrates with IIoT, cloud analytics, and open protocols for data-driven process optimisation and predictive maintenance.

⚙️Use Cases and Industries

Typical Industries

Chemical, petrochemical, and refinery plants

Power generation and utilities

Water and wastewater treatment

Pharmaceutical, food & beverage, pulp & paper

Mining and metals processing

Why DCS Fits

DCS is ideal where:

Thousands of control loops operate simultaneously

High availability is essential

Continuous or batch processes require precise real-time control

⚙️Benefits of Implementing a DCS

Reliability & Fault Tolerance

Distributed nodes reduce the risk of a full system shutdown.

Scalability & Flexibility

Easily add new control loops or expand the system without redesigning a central controller.

Process Efficiency & Data-Driven Optimisation

Integrated data logging and analytics improve yields, energy efficiency, and reduce downtime.

Operator Experience

Modern HMI displays, alarms, and trend analytics provide better control and visibility.

Safety & Cybersecurity

Central oversight of distributed units supports safety instrumentation and cybersecurity strategies.

⚙️DCS vs PLC vs SCADA

DCS vs PLC: PLCs control individual machines; DCS controls entire plants with thousands of interlinked loops.

DCS vs SCADA: SCADA focuses on remote monitoring; DCS provides real-time control with integrated process loops.

Selecting the right system depends on process size, number of loops, uptime requirements, and scalability.

⚙️Key Considerations for Deployment

♦ Network & Communication: High-speed, low-latency networks with redundancy are essential.

♦ Connectivity Hardware: Industrial-grade RJ45 connectors and USB/RJ45 combo connectors from LINK‑PP ensure reliable field-to-controller communication.

♦ Cybersecurity: Secure architecture, segmentation, and intrusion detection are critical in connected DCS systems.

♦ Operator Training: Staff must effectively use HMI, alarms, and trends.

♦ Vendor Choice & Open Architecture: Multi-vendor interoperability and open standards support future-proof systems.

⚙️Future Trends in DCS

IIoT & Edge Computing: Controllers integrate edge analytics and cloud connectivity.

AI & Machine Learning: Real-time data enables predictive maintenance and process optimisation.

Cybersecurity & Open Systems: Increased connectivity requires secure, open architectures.

Digital Twins & Sustainability: DCS interfaces with simulation models to optimise energy and processes.

⚙️How LINK‑PP Supports DCS Deployments

LINK‑PP’s RJ45 connectors, USB/RJ45 combo connectors, and other industrial connectivity products offer:

Durable, industrial-grade design for harsh environments

Compatibility with high-speed Ethernet networks used in DCS systems

Reliable, low-latency connections for field-to-controller communication

Streamlined global supply for automation integrators

⚙️Summary

DCS distributes control across multiple nodes, improving reliability and real-time performance.

Suited for large-scale continuous and batch process industries.

Benefits include scalability, efficiency, operator visibility, safety, and optimisation.

DCS differs from PLCs (machine-level control) and SCADA (remote monitoring).

Deployment requires attention to network architecture, connectivity, cybersecurity, training, and vendor strategy.

Future DCS trends include IIoT integration, AI-driven optimisation, open architectures, digital twins, and sustainability.

LINK‑PP connectivity solutions provide the reliable infrastructure DCS systems need for modern industrial automation.