I/O modules are essential components in modern automation, networking, and industrial control infrastructure. They collect sensor data, interface with field devices, and communicate with controllers or network equipment. At the heart of this communication lies the RJ45 connector—the primary physical interface enabling Ethernet-based data exchange.

This article provides a technical overview of how RJ45 connectors support I/O module performance, reliability, and integration within industrial Ethernet architectures.

1. RJ45 as the Primary Ethernet Interface for I/O Modules

In both networking and industrial control systems, RJ45 connectors serve as the standard physical port for:

10/100/1000Mbps Ethernet

Full-duplex and auto-negotiation

Protocols such as Modbus TCP, EtherNet/IP, PROFINET, CC-Link IE, and general TCP/IP traffic

By linking I/O modules to PLCs, IPCs, industrial switches, and SCADA servers, RJ45 interfaces enable simple, standardized, and universally interoperable Ethernet communication.

In essence, the RJ45 port transforms an I/O module from a standalone device into a fully networked system component.

2. Stable Upstream and Downstream Communication

I/O modules rely on RJ45 interfaces to handle two major communication paths:

Upstream (I/O → Controller)

Sensor measurements

Device status

Time-sensitive industrial data

Downstream (Controller → I/O)

Control commands

Configuration data

Firmware updates

This bi-directional data flow forms the backbone of industrial automation networks, where real-time responsiveness and packet integrity directly impact system performance.

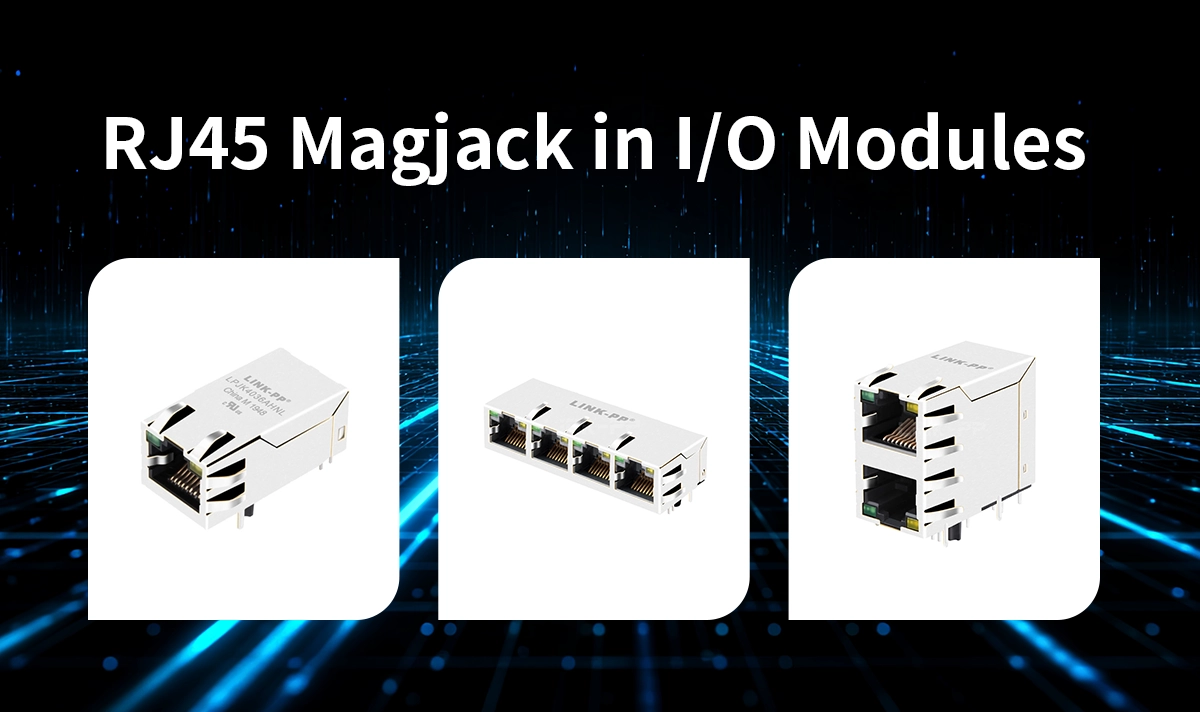

3. Enhanced Signal Integrity Through Integrated Magnetics

Many industrial I/O modules use integrated RJ45 connectors (Magjack) to improve electrical performance. These components incorporate:

Isolation transformers

Common-mode chokes

EMI/EMC filtering structures

Advantages include:

1.5–2.5 kV isolation between PHY and external network

Reduced noise coupling in high-interference environments

Improved signal integrity across longer cable distances

In factory automation scenarios involving motors, drives, and switching equipment, this magnetic isolation is essential for maintaining stable Ethernet links.

4. Power Over Ethernet (PoE) Capability

A growing number of I/O modules support Power over Ethernet, enabling both data and power to be delivered through the same RJ45 connector. This offers several benefits:

Eliminates separate power wiring

Simplifies installation for remote or distributed I/O

Reduces system cost and physical footprint

Supports devices in hard-to-reach locations

PoE makes RJ45 particularly attractive for IIoT edge nodes, compact measurement modules, and distributed factory sensors.

5. Modularity, Maintainability, and Field Serviceability

RJ45 connectors bring mechanical advantages crucial for industrial environments:

Hot-swappable in many Ethernet-based I/O systems

Fast and clean installation

Tool-free replacement

High durability with shielded metal shells

This allows technicians to replace I/O modules or cables quickly—minimizing downtime and easing system expansion.

6. Why Industrial Devices Prefer Shielded RJ45 Connectors

Shielded and EMI-hardened RJ45 connectors are widely used in I/O modules because they help:

Reduce electromagnetic susceptibility

Maintain signal stability near motors or high-voltage equipment

Support grounding paths for improved noise protection

This is why high-EMC industrial designs almost always specify shielded RJ45 Magjack components.

Conclusion

RJ45 connectors play a foundational role in how I/O modules interact within modern networked and industrial systems. From enabling Ethernet communication and PoE power delivery to improving electrical isolation and field serviceability, the RJ45 interface is far more than a simple port—it's a critical element determining the reliability and performance of industrial automation networks.

For engineers designing next-generation I/O modules, selecting a high-quality industrial RJ45 connector is essential for guaranteeing system stability and long-term operation.