Modern high-speed Ethernet—10G, 25G, 40G, 100G and beyond—relies on a layered architecture that ensures data can move reliably from the MAC layer to the physical transmission medium. Among these layers, PCS (Physical Coding Sublayer), PMA (Physical Medium Attachment), and PMD (Physical Medium Dependent) form the core of the physical-layer (PHY) stack.

Although closely related, each layer performs a distinct function. Understanding how they operate together is essential for network engineers, optical module designers, and anyone evaluating Ethernet transceivers or connectivity hardware.

1. What Each Layer Does

PCS — Physical Coding Sublayer

PCS handles data encoding, block alignment, lane distribution, and error detection.

Key responsibilities include:

Encoding schemes (8b/10b, 64b/66b, 256b/257b)

Lane striping and deskew (for multi-lane Ethernet)

Word alignment and frame delineation

Error monitoring (BER, block error)

PCS converts MAC-layer data into a coded bitstream suitable for high-speed serialization.

PMA — Physical Medium Attachment

PMA is responsible for serialization/deserialization, clock recovery, and electrical adaptation between PCS and PMD.

Its main functions:

SerDes (parallel-to-serial and serial-to-parallel conversion)

CDR (clock and data recovery)

Generating stable high-speed bit streams for transmission

Combining multiple lanes (e.g., 4×25G → 100G)

Handling the electrical PHY interface inside a transceiver

PMA ensures the signal is clean, synchronized, and ready for transmission over the medium.

PMD — Physical Medium Dependent

PMD is the layer that interacts directly with the actual transmission medium, such as fiber, copper, DAC, or AOC.

PMD includes:

Optical transmitters/receivers (e.g., lasers, photodiodes)

Electrical drivers and amplifiers

Wavelength selection

Launch power and sensitivity control

Medium-specific parameters (OM3/OM4 fiber, 100-ohm copper pairs, etc.)

PMD converts the electrical signal from PMA into optical or copper-based signals that travel over the physical link.

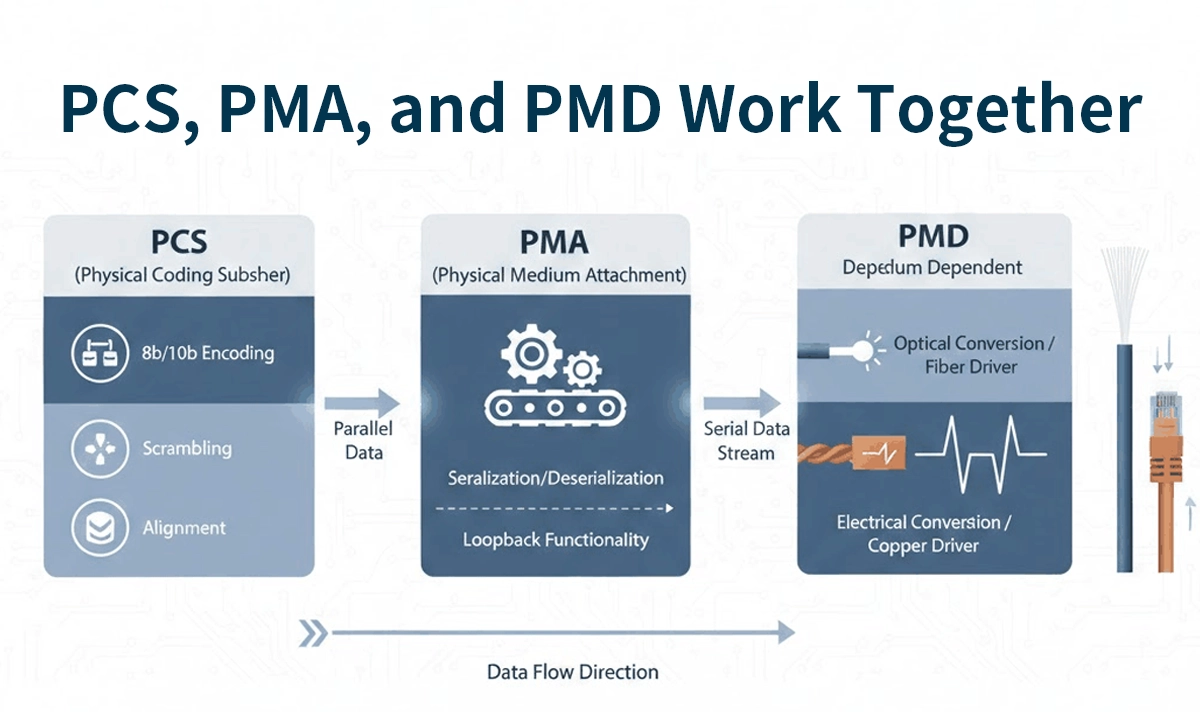

2. How PCS, PMA, and PMD Work Together

The flow of data through the PHY stack follows this pipeline:

Step 1: PCS Encodes and Organizes Data

Data from the MAC is:

Encoded (64b/66b or others)

Distributed into lanes (if multi-lane)

Aligned and block-locked

This prepares the data for high-speed serialization while maintaining signal integrity.

Step 2: PMA Converts and Synchronizes the Bitstream

PMA:

Serializes the PCS-coded data into a continuous bitstream

Recovers clock timing from incoming data

Applies SerDes equalization and retiming

Ensures lane bonding for multi-lane protocols (XLAUI, CAUI-4, etc.)

This stabilizes the signal before transmission.

Step 3: PMD Sends the Signal Through the Medium

The PMD layer:

Converts electrical signals into optical signals (via laser/photodiode)

Or adapts electrical outputs for copper (BASE-T, DAC)

On the receiving side, PMD reverses the process and passes clean electrical signals back to the PMA.

3. Why These Layers Matter

For optical transceiver performance

These layers determine:

Maximum data rate

Link distance capability

Error performance (BER)

Latency

Power efficiency

PMA and PMD are especially critical in 100G/200G/400G PAM4 transceivers, where clock recovery and optical modulation require advanced DSP.

For system integrators

A clear understanding of PCS-PMA-PMD interactions helps with:

Selecting compatible SFP/QSFP modules

Troubleshooting optical link issues

Ensuring correct lane mapping (e.g., breakouts)

Diagnosing coding or alignment errors

4. How LINK-PP Hardware Supports PCS/PMA/PMD Stability

LINK-PP provides Ethernet magnetic components, optical transceiver accessories, and high-performance connectivity parts engineered for:

Low insertion loss and high signal integrity (supports PMA SerDes performance)

EMI suppression for stable PCS/PMA operations

Robust electrical characteristics for long-distance links

Compatibility with major networking OEMs

High-quality connectors, RJ45 magnetics, and optical components help maintain signal clarity across all PHY sublayers, ensuring reliable operation from PCS encoding to PMD transmission.

Conclusion

PCS, PMA, and PMD work together as three synchronized layers of the Ethernet PHY, forming the essential pipeline that allows high-speed data to travel cleanly and reliably across fiber and copper networks.

PCS handles coding and alignment

PMA handles serialization and timing

PMD handles medium-specific transmission

Understanding their roles is fundamental when evaluating high-speed optical modules, network designs, or physical-layer performance.