▶ RTU Overview

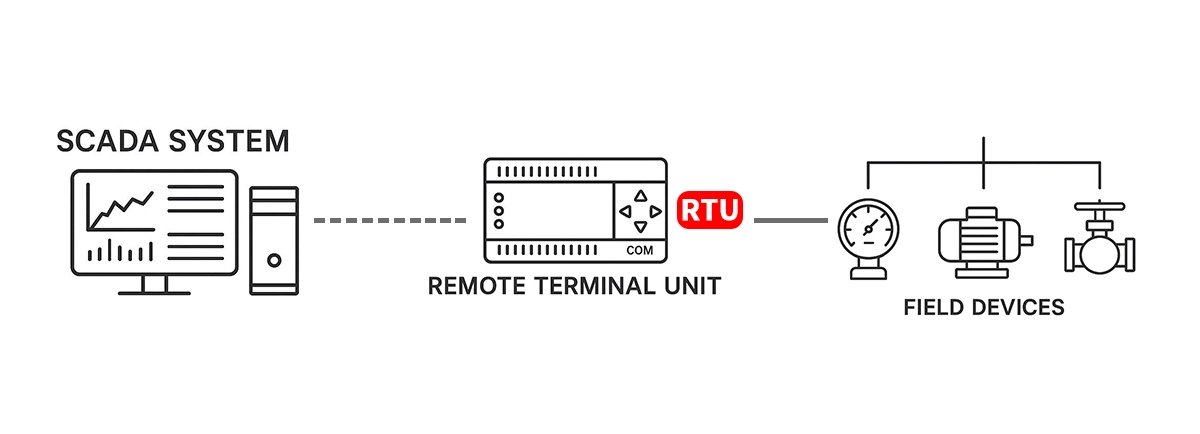

Remote Terminal Units (RTUs) are field-deployed, microprocessor-based devices designed to interface between field equipment and supervisory control systems. They collect measurement data, execute control logic, and transmit real-time status, alarms, and events to SCADA or DCS systems. RTUs are engineered for remote, rugged, and often unmanned environments, making them essential in electric utilities, oil & gas pipelines, water systems, transportation, and industrial energy networks.

▶ What an RTU Does

Core capabilities

Data acquisition: Analog and digital signal measurement from sensors, transmitters, meters

Local logic: Event triggers, basic control sequences, time-stamped alarms

Command execution: Operating relays, switches, pumps, and valves

Telecontrol communication: Sending telemetry to SCADA and receiving control commands

Event recording: Logging abnormal conditions and fault records

Cybersecurity features: Authentication, access control, encrypted sessions (in modern designs)

Typical interfaces

Digital Inputs (DI) — breaker status, alarms

Analog Inputs (AI) — 4–20 mA, 0–10 V, voltage/frequency signals

Digital Outputs (DO) — relays, contact closure

Analog Outputs (AO) — proportional control signals

Communication Ports — RS-232, RS-485, fiber, cellular, radio, industrial Ethernet

▶ RTU vs PLC

Item | RTU | PLC |

|---|---|---|

Primary role | Remote monitoring & telecontrol | Fast local automation & motion control |

Strength | Robust communications & remote reliability | Millisecond-level logic execution |

Deployment | Substations, pipelines, remote water sites | Manufacturing lines, machinery |

Power profile | Often low-power / solar-ready | Typically higher power |

Rule of thumb:

RTU = communications & telemetry in harsh/remote sites

PLC = fast industrial control in plant environments

In modern systems, RTUs and PLCs are often integrated, not competing.

▶ Communication Protocols Used by RTUs

Modbus (RTU / TCP)

A widely-adopted and simple request-response protocol for telemetry.

Modbus RTU — serial

Modbus TCP — Ethernet

DNP3

Designed for electric power automation and critical infrastructure; supports time-stamping, unsolicited events, and robust reporting.

IEC 60870-5 / IEC 60870-5-104

Common in European and global utility telecontrol applications; supports remote station-to-master communication in power systems.

IEC 61850 (in modern RTUs)

Used in substation automation with advanced messaging, including GOOSE and MMS services.

▶ Environmental & Reliability Considerations

RTUs must endure:

Wide temperature variation

Lightning/surge exposure

Unstable power or solar supply

Dust, humidity, vibration

Field devices often run for 10-20+ years without frequent site visits. Hardware ruggedness is not optional—it is mission-critical.

▶ RTU Cybersecurity Best Practices

Unique, role-based access credentials

Enforced encryption and secure protocols where supported

Network segmentation between OT and IT networks

Disable unused ports/services

VPN or encrypted tunnel for remote maintenance

Time sync for reliable logs (NTP / PTP)

Firmware update policy & trusted signing

▶ Hardware Connectivity: Why Ethernet Matters

Modern RTUs increasingly rely on Ethernet-based SCADA architectures and industrial IP networks. Reliable physical-layer design is key to availability.

Key Ethernet Interface Requirements

Integrated magnetics for signal integrity

PoE options for powering field devices

EMI/ESD protection

Industrial temperature rating

Mechanical durability for field cabinets

▶ LINK-PP Solutions for RTUs and Industrial Gateways

RTU and edge gateway manufacturers depend on rugged, high-performance connectors to maintain reliable data links.

Recommended LINK-PP features for RTU communication ports:

Integrated RJ45 MagJack with isolation transformers

10/100/1000Base-T support

Industrial temperature options

EMI shielding & surge protection

PoE / PoE+ capable variants for field devices

LINK-PP provides compatible RJ45 magnetics and Ethernet connector solutions used in industrial automation, power grid equipment, and remote telemetry platforms.

▶ Deployment Checklist

Define I/O count, scan rate, and protocol needs

Validate SCADA master/RTU protocol compatibility

Harden device credentials & disable unused services

Use industrial-grade Ethernet magnetics/ports

Implement surge and grounding design

Plan remote firmware & logging strategy

▶ Conclusion

Remote Terminal Units remain foundational to modern industrial control and SCADA systems. As utilities and critical infrastructure modernize toward Ethernet-based and cybersecurity-hardened architectures, RTUs must combine proven field durability with modern protocols and secure communication interfaces.

High-performance physical network components—such as LINK-PP industrial Ethernet connectors and MagJacks—help ensure reliable communication in demanding field environments, reduce maintenance cycles, and safeguard mission-critical telemetry operations.