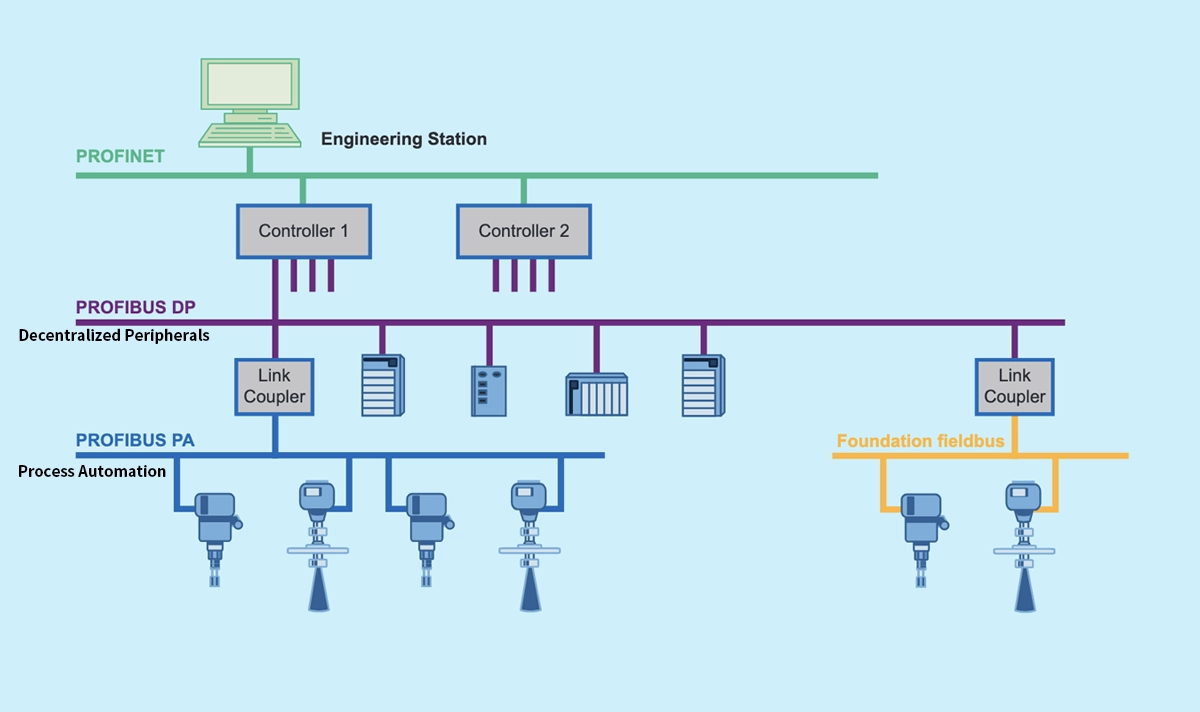

PROFIBUS (Process Field Bus) is one of the world’s most established fieldbus standards, widely used in industrial automation to connect controllers, sensors, actuators, and distributed I/O modules. Standardized under IEC 61158, it offers deterministic serial communication, long-distance coverage, and robust real-time performance. While Ethernet-based technologies such as PROFINET are increasingly adopted, PROFIBUS remains essential in many factories due to its maturity, reliability, and vast installed base.

This guide explains PROFIBUS terminology, protocol types, network architecture, and practical applications. It also highlights how LINK-PP industrial-grade RJ45 connectors support hybrid PROFIBUS–Ethernet systems in modern automation.

✅ What Is PROFIBUS?

PROFIBUS is an open, vendor-neutral fieldbus protocol designed for industrial communication between PLCs, field devices, and control systems. Unlike Ethernet, it uses serial communication—mainly over RS-485 or MBP—to provide deterministic and stable cyclic data exchange.

Key Characteristics

Deterministic real-time field communication

Cable distances up to 1,200 meters per RS-485 segment

Multi-drop bus topology for simple installation

Wide ecosystem of certified devices

Strong reliability in electromagnetic and harsh environments

✅ PROFIBUS Protocol Types

▶ PROFIBUS DP (Decentralized Peripherals)

PROFIBUS DP is the most commonly deployed version, optimized for factory automation and high-speed device communication.

1. Technical Features

Baud rates up to 12 Mbps

RS-485 physical layer

Cyclic and acyclic data exchange

Supports remote I/O, sensors, actuators, and drives

2. Typical Applications

Assembly lines

Material handling

CNC and robotics systems

High-speed machine control

▶ PROFIBUS PA (Process Automation)

Designed for hazardous and process-oriented environments, PROFIBUS PA is widely used in chemical, energy, and pharmaceutical industries.

1. Technical Features

Based on MBP (Manchester Bus Powered)

31.25 kbps baud rate

Power and data on the same pair of wires

Intrinsically safe variants for explosive environments

2. Typical Applications

Flow, pressure, and temperature instruments

Field measurement devices

Distributed control systems in process plants

✅ How PROFIBUS Communication Works

Master/Slave Architecture

PROFIBUS operates with master devices (PLCs, DCS controllers) managing communication cycles, while slave devices (sensors, actuators, I/O modules) respond within predefined time slots.

Deterministic Cyclic Data Exchange

The controller polls all devices cyclically, ensuring predictable timing critical for automation processes.

Token Passing

In multi-master networks, a token-passing mechanism ensures orderly network control between masters.

✅ Network Structure and Physical Layer

PROFIBUS DP Using RS-485

Linear bus topology

32 devices per segment directly (more with repeaters)

Shielded twisted-pair cable

Termination is required at both ends

PROFIBUS PA Using MBP

Two-wire system carrying both data and power

Long-distance capability

Supports intrinsically safe field devices

✅ Advantages of PROFIBUS

♦ Proven Reliability

Its robust physical layer makes PROFIBUS highly resistant to noise, interference, and harsh plant conditions.

♦ Cost Efficiency

Affordable device pricing and simple installation make PROFIBUS a cost-effective fieldbus option.

♦ Mature, Stable Technology

With decades of global adoption, it offers excellent long-term support and diagnostic tools.

♦ Easy Integration With Legacy Equipment

Ideal for plants requiring modern control upgrades without a complete network replacement.

✅ PROFIBUS vs. PROFINET

Feature | PROFIBUS | |

|---|---|---|

Technology | Serial RS-485/MBP | Industrial Ethernet |

Speed | Up to 12 Mbps | Up to Gigabit Ethernet |

Distance | Very long | Standard Ethernet limits |

Determinism | High | RT/IRT options |

Installation | Bus topology | Star/line/ring/tree |

Applications | Legacy and stable systems | Modern high-speed systems |

Many plants deploy both protocols—PROFIBUS at the field level and PROFINET or Ethernet upstream.

✅ Hardware Considerations in PROFIBUS Systems

PROFIBUS field devices typically use RS-485 or MBP connectors such as DB9, terminal blocks, or PA couplers. However, many hybrid PLCs, gateways, HMIs, and DCS modules also include Ethernet ports for management, engineering, diagnostics, or PROFINET connectivity.

When RJ45 Connectors Matter in PROFIBUS Environments

LINK-PP integrated RJ45 connectors play a key role in:

PROFIBUS–PROFINET gateways

PLCs featuring both serial and Ethernet ports

Industrial switches used in mixed-architecture networks

SCADA and engineering workstations connected via Ethernet

Benefits of LINK-PP Industrial RJ45 Connectors

Robust shielding for EMI-heavy industrial sites

Integrated magnetics for strong Ethernet PHY performance

Stable data transmission in automation panels

Compact, durable design for industrial controllers

▶ Product catalog:

LINK-PP Integrated RJ45 Connector Series

✅ Common PROFIBUS Use Cases

1. Factory Automation

Motors and drives

Conveyor systems

Packaging and handling machinery

2. Process Automation

Field sensors and transmitters

Valve positioners

Monitoring and control loops

3. Plant Modernization

PROFIBUS remains the preferred option for stable legacy systems requiring long-term reliability.

✅ Frequently Asked Questions (FAQ)

Q1: Is PROFIBUS still used today?

Yes. Despite the rise of Industrial Ethernet systems, PROFIBUS remains widely used, especially in process industries and legacy manufacturing facilities. Its long-term stability and extensive installed base keep it relevant.

Q2: What is the main difference between PROFIBUS DP and PA?

DP is designed for high-speed factory automation using RS-485, while PA is optimized for process environments, uses MBP cabling, and supports intrinsically safe devices.

Q3: How far can PROFIBUS signals travel?

RS-485 PROFIBUS DP supports up to 1,200 meters at lower baud rates. PROFIBUS PA allows even longer distances depending on power and topology.

Q4: Can PROFIBUS and PROFINET operate together?

Yes. Many systems use PROFIBUS at the field level and PROFINET for backbone communication. Gateways and hybrid PLCs bridge the two protocols.

Q5: Why are RJ45 connectors relevant if PROFIBUS does not use Ethernet?

Modern controllers and gateways often combine PROFIBUS ports with Ethernet interfaces for diagnostics, configuration, SCADA connectivity, or PROFINET communication. High-quality RJ45 connectors ensure stable Ethernet links in these mixed networks.

✅ Conclution

PROFIBUS is a robust and proven fieldbus protocol widely used for connecting industrial devices in both manufacturing and process automation. Its deterministic timing, long-distance capability, and strong reliability make it ideal for stable automation environments. As modern plants increasingly integrate fieldbus with Ethernet-based networks, LINK-PP’s industrial-grade RJ45 connectors provide reliable connectivity between controllers, gateways, and SCADA systems—ensuring long-term performance in demanding industrial applications.