PROFINET (Process Field Network) is one of the leading Industrial Ethernet standards defined by PROFIBUS & PROFINET International (PI). Designed for real-time communication, high reliability, and seamless integration with automation devices, PROFINET enables modern factories to connect controllers, sensors, actuators, and edge systems with deterministic performance.

This guide explains the terminology, architecture, communication mechanisms, and hardware considerations associated with PROFINET, while highlighting how LINK-PP integrated RJ45 connectors enhance industrial network reliability.

➡️ What Is PROFINET?

PROFINET is an open Industrial Ethernet protocol that supports real-time data exchange between industrial controllers (PLCs, DCS) and field devices. It is built on standard IEEE 802.3 Ethernet but adds deterministic communication, network diagnostics, and device configuration features required in automation environments.

Key Technical Characteristics

Real-Time Determinism: Essential for motion control and time-critical operations

Scalable Performance: Ranges from standard real-time to isochronous real-time

Flexible Topologies: Line, star, ring, tree, and mixed architectures

IT/OT Integration: Combines industrial field communication with standard IP protocols

High Reliability: Supports redundancy, fast recovery, and robust error detection

➡️ How PROFINET Communication Works

PROFINET defines three communication classes to meet different industrial requirements. Each level builds upon standard Ethernet, adding timing and determinism mechanisms.

PROFINET Communication Classes

1. PROFINET NRT — Non-Real Time

Based on standard TCP/IP

Used for configuration, parameterization, and diagnostics

Suitable for applications not requiring deterministic timing

2. PROFINET RT — Real Time

Bypasses TCP/IP to reduce latency

Cycle times typically 1–10 ms

Used for general automation tasks (I/O, sensors, drives)

3. PROFINET IRT — Isochronous Real Time

Uses time-scheduling and bandwidth reservation

Cycle times <1 ms with jitter <1 µs

Required for multi-axis motion control and synchronized robotics

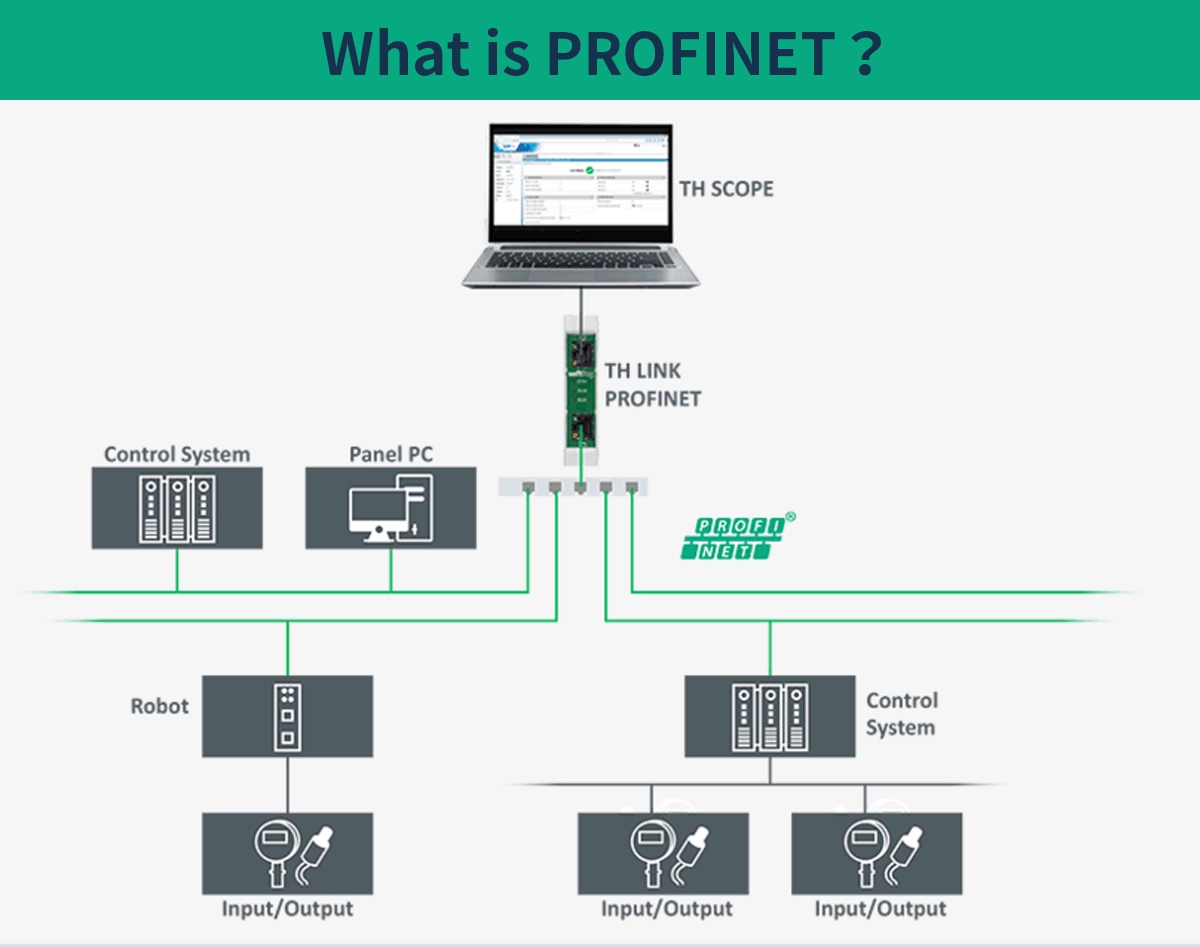

➡️ PROFINET Architecture and Device Classes

PROFINET organizes devices into functional roles to streamline configuration and communication.

▷ Device Classes

IO-Controller: Central controller, such as a PLC

IO-Device: Field devices (I/O modules, sensors, actuators)

IO-Supervisor: Engineering, monitoring, or diagnostic tools

▷ PROFINET Topologies

PROFINET supports multiple network layouts depending on installation design:

Star topology: Common with switches and modular network designs

Line topology: Cost-saving, used for daisy-chained field devices

Ring topology: Offers redundancy with Media Redundancy Protocol (MRP)

➡️ Technical Features and Advantages of PROFINET

▶ Robust Real-Time Performance

PROFINET achieves deterministic communication through traffic prioritization, dedicated real-time channels, and integrated synchronization (in IRT).

▶ Integration With Existing Systems

Because PROFINET runs over standard Ethernet hardware, it easily integrates with corporate networks, SCADA systems, and Industrial IoT platforms.

▶ High Scalability

Supports simple sensors, complex motion systems, and high-bandwidth applications all within the same network.

▶ Advanced Diagnostics

Device naming and identification

Asset management

Real-time status monitoring

Automatic device replacement without reconfiguration

➡️ Common PROFINET Use Cases

1. Factory Automation

Assembly lines, robotic control, packaging systems, and conveyor systems require real-time data exchange.

2. Process Automation

Chemical, pharmaceutical, and energy sectors use distributed I/O modules and safety-critical devices.

3. Motion Control Systems (PROFINET IRT)

Precision robotics, CNC machines, and synchronized multi-axis equipment.

4. Industrial IoT & Smart Manufacturing

Connecting field devices to edge gateways and analytics platforms.

➡️ Hardware Requirements for Reliable PROFINET Networks

While PROFINET uses standard Ethernet physical layers, industrial environments demand reinforced connectors, magnetics, and EMI-hardened components.

Key Hardware Considerations

Shielded twisted-pair cabling with industrial-grade insulation

Robust RJ45 connectors with enhanced EMI protection

High-quality integrated magnetics supporting 10/100/1000Base-T

Mechanical durability against vibration, shock, and temperature fluctuations

How LINK-PP Integrated RJ45 Connectors Support PROFINET Performance

High-reliability connectors are critical in industrial automation networks. LINK-PP’s RJ45 Magjack solutions provide stable, low-noise Ethernet performance suitable for PROFINET RT and NRT environments.

Optimized Magnetics: Ensures stable signal integrity for 10/100/1000 Mbps PROFINET communication

Excellent EMI Suppression: Reduces common-mode noise in harsh industrial conditions

Industry-Grade Shielding: Metal shell structures protect against electromagnetic interference

Long Service Life: Suitable for industrial PLCs, I/O modules, HMIs, and embedded PROFINET devices

Compact Integration: Saves PCB space and improves thermal performance

These connectors provide the physical reliability needed for PROFINET networks to operate at peak performance, especially in environments prone to vibration, electrical noise, or extreme temperatures.

➡️ PROFINET vs. Other Industrial Ethernet Protocols

PROFINET vs. EtherNet/IP

Feature | PROFINET | EtherNet/IP |

|---|---|---|

Real-time class | RT, IRT | CIP Sync (less deterministic) |

Motion control | Strong (IRT) | Moderate |

Determinism | Very high | Medium |

Topologies | Flexible | Star-centric |

Adoption | Strong in EU/Asia | Strong in North America |

PROFINET vs. EtherCAT

EtherCAT is faster for motion applications

PROFINET offers broader interoperability and easier integration

Hardware requirements for EtherCAT are more specialized

➡️ Summary

PROFINET is a powerful and flexible Industrial Ethernet standard designed for automation environments requiring reliability, determinism, and scalable performance. Its real-time communication classes (RT and IRT), expansive device ecosystem, and diagnostic features make it a cornerstone of modern industrial networking.

By pairing PROFINET systems with high-quality hardware—such as LINK-PP integrated RJ45 connectors—engineers can achieve improved signal integrity, long-term reliability, and stable network performance.

LINK-PP’s products help ensure smooth operation across industrial controllers, I/O systems, sensors, and networking modules, supporting the full potential of PROFINET-enabled automation.

➡️ Also SEE

Enhance your understanding of industrial networking with these related technical resources from LINK-PP:

Distributed Control Systems (DCS) in Industrial Automation

A quick guide to DCS architecture, redundancy, and industrial use cases.PLC (Programmable Logic Controller) Guide for Industrial Automation

Key concepts of PLC operation, programming, and communication interfaces

What Is Electromagnetic Interference (EMI)?

A clear explanation of EMI sources and suppression methods in electronic systems.What Are SCADA Systems?

A concise overview of Supervisory Control and Data Acquisition architectures and applications.Understanding I/O Modules in Automation and Networking

A practical guide to digital, analog, and networked I/O modules used in industrial control.TCP/IP Model: Network Communication Layers and Data Exchange Explained

A complete breakdown of the TCP/IP stack and how data moves across modern networks.IEEE 802.3 Ethernet Standard Explained

A technical introduction to Ethernet physical layers, MAC functions, and frame structures.