PROFINET and PROFIBUS are two of the most widely used industrial communication protocols in factory automation, process control, and machine networking. Though both originate from PROFIBUS & PROFINET International (PI), they serve different technical needs, architectures, and performance requirements. Understanding their differences helps engineers design scalable, reliable, and future-ready automation systems.

LINK-PP supports both communication ecosystems with industrial-grade RJ45 magnetic jacks and related Ethernet connectivity components widely used in PLCs, controllers, robots, and industrial I/O systems.

🔁 What Is PROFINET?

PROFINET (Process Field Network) is an Ethernet-based industrial communication protocol designed for high-speed, real-time data exchange. Built on IEEE 802.3 Ethernet standards, it supports deterministic communication for critical automation tasks.

Key Characteristics of PROFINET

Runs on standard Industrial Ethernet (100/1000 Mbps).

Supports Real-Time (RT) and Isochronous Real-Time (IRT) communication.

Highly scalable for Industry 4.0 applications.

Integrates seamlessly with IP-based protocols (TCP/IP, HTTP, SNMP).

Ideal for motion control, robotics, and time-sensitive automation.

Physical Layer

PROFINET uses Ethernet PHY and commonly terminates with RJ45 Magjack connectors, such as LINK-PP integrated RJ45 modules built for EMC stability, low insertion loss, and high durability in industrial environments.

🔁 What Is PROFIBUS?

PROFIBUS (Process Field Bus) is a serial fieldbus protocol widely used in automation and process industries since the 1990s. It uses RS-485-based communication and offers deterministic data exchange for sensors, actuators, and controllers.

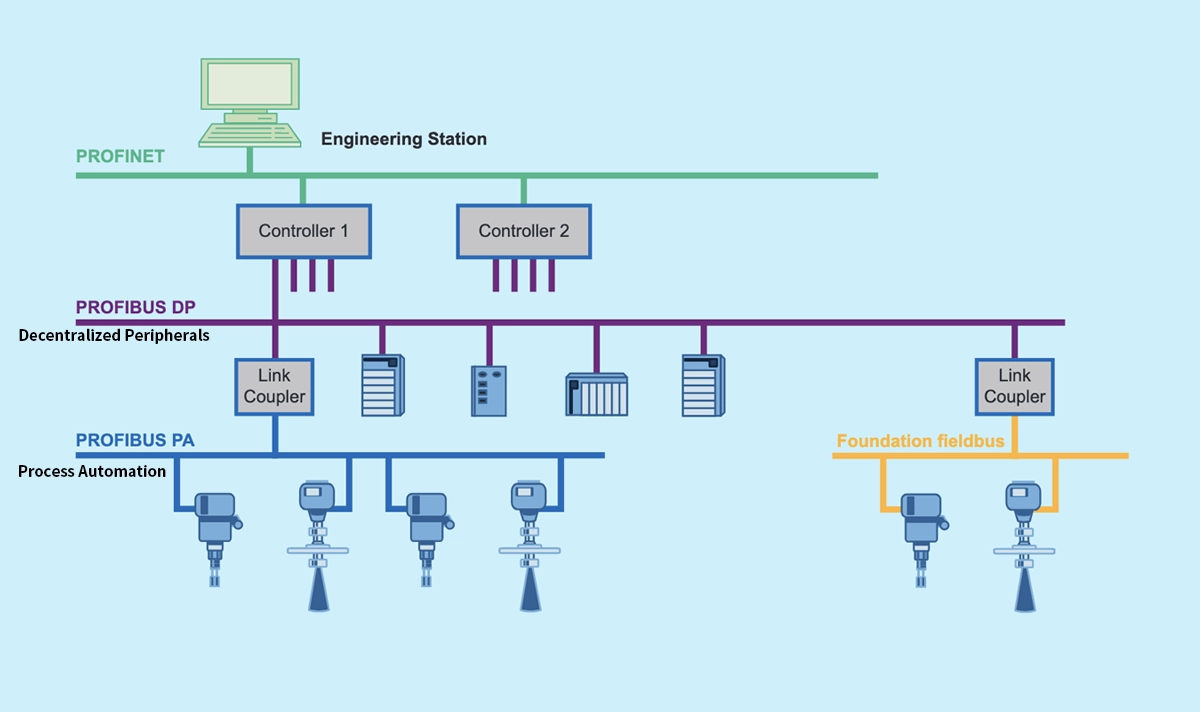

Main PROFIBUS Variants

PROFIBUS DP (Decentralized Peripherals): High-speed communication for factory automation.

PROFIBUS PA (Process Automation): Intrinsically safe communication for hazardous environments.

Physical Layer

PROFIBUS DP uses shielded twisted-pair cable (RS-485).

PROFIBUS PA uses MBP (Manchester Bus Powered).

Connectors include DB9, terminal blocks, or PROFIBUS field connectors.

🔁 PROFINET vs PROFIBUS: Core Differences

▶ Comparison Overview

Feature | PROFINET | PROFIBUS |

|---|---|---|

Communication Type | Ethernet-based | Serial RS-485 / MBP |

Data Rate | 100/1000 Mbps | 9.6 kbps – 12 Mbps |

Topology | Star, line, ring | Line |

Real-Time Capabilities | RT / IRT | Deterministic but slower |

Physical Medium | Cat5e/Cat6 & RJ45 | RS-485 cable / PA cable |

Best for | Robotics, motion control, high-speed automation | Sensors, actuators, stable process control |

Diagnostics | Advanced IT integration, web diagnostics | Limited but reliable |

Industry 4.0 Support | Strong | Moderate |

▶ When to Use PROFINET

PROFINET is the preferred choice when:

High-speed deterministic communication is required.

Systems need integration with industrial Ethernet networks.

Applications involve robotics, CNC machines, or synchronized drives.

You require easy integration with modern PLCs, SCADA, and MES systems.

LINK-PP’s PROFINET-compatible RJ45 integrated connectors provide enhanced EMI suppression, compact footprint, and stable transmission for Industrial Ethernet devices.

▶ When to Use PROFIBUS

Choose PROFIBUS when:

A mature, stable, long-distance fieldbus is needed.

Devices operate in hazardous or process-control environments.

You need a simple, deterministic, and proven communication setup.

Existing installations require incremental upgrades rather than full Ethernet migration.

🔁 Migration Trends — From PROFIBUS to PROFINET

Industrial networks are transitioning from serial fieldbus systems to Ethernet-based architectures. Key reasons include:

The rise of Industrial IoT (IIoT)

Need for higher bandwidth and real-time control

Better diagnostics and remote management

Compatibility with modern PLCs and industrial controllers

However, PROFIBUS remains widely used, especially in process industries where intrinsic safety and long cable distances are critical.

🔁 How LINK-PP Components Support PROFINET & PROFIBUS Systems

LINK-PP provides connectivity components used across automation ecosystems:

1. For PROFINET Systems

Industrial RJ45 integrated connectors (with magnetic modules)

Enhanced EMI suppression for reliable real-time Ethernet

Shielded PCB RJ45 jacks for switches, PLCs, and I/O modules

2. For PROFIBUS Systems

High-reliability isolation transformers and connectors in gateway or communication module designs

Custom PCB connectors used in PROFIBUS-to-PROFINET converters

🔁 FAQ

Q1: Is PROFINET replacing PROFIBUS?

Yes, in many new installations. However, PROFIBUS remains widely used in process and legacy systems.

Q2: Can PROFINET and PROFIBUS work together?

Yes. Gateways and PLCs with dual interfaces allow both protocols to coexist in hybrid networks.

Q3: Which protocol is better for motion control?

PROFINET IRT is superior due to precise synchronization and high-speed updates.

Q4: Which is easier to maintain?

PROFINET offers advanced diagnostics via web interfaces and standard Ethernet tools, making it easier for modern maintenance workflows.

Q5: What connectors are recommended for PROFINET devices?

Industrial-grade RJ45 integrated Magjack connectors, such as those offered by LINK-PP, ensure stable and EMI-resistant Ethernet communication.

🔁 Also See

What Is Electromagnetic Interference (EMI)?

Learn how EMI impacts industrial communication reliability.What Are SCADA Systems?

A quick overview of SCADA architecture and applications.Understanding I/O Modules in Automation and Networking

Explore how I/O modules connect sensors, actuators, and controllers.TCP/IP Model Explained

Understand the layered communication foundation behind PROFINET.IEEE 802.3 Ethernet Standard

Technical background on Ethernet, the basis for PROFINET systems.Distributed Control Systems (DCS)

Learn how DCS architectures shape industrial automation.PLC Guide for Industrial Automation

A complete introduction to PLC operations and communication.